A touch panel and a manufacturing method thereof

A touch panel and manufacturing method technology, applied in the fields of instruments, computing, electrical digital data processing, etc., can solve problems such as insulation drop and short circuit, and achieve the effect of enhancing electrical insulation and reducing the risk of silver migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

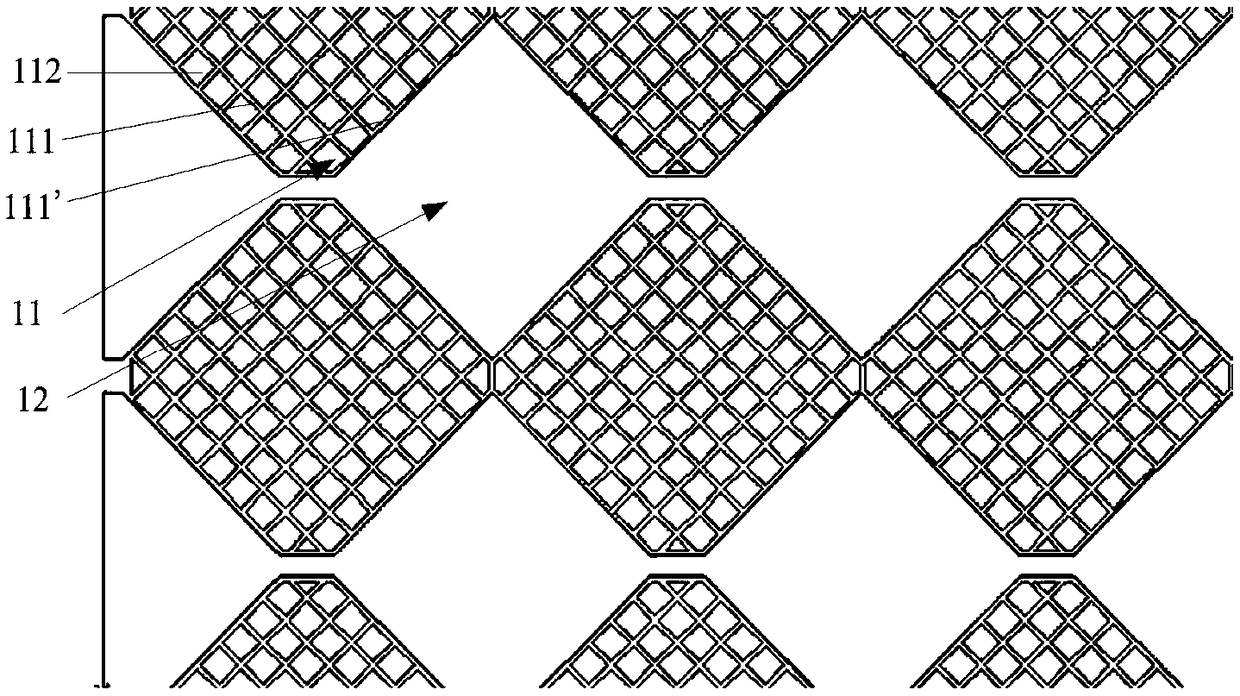

[0031] Such as figure 2 As shown, it is a top view of the conductive layer in the prior art, such as figure 2 As shown, the conductive layer includes a dummy wiring area (Dummy Pattern) 11 and a functional area 12 . Wherein the dummy wiring area 11 is distributed in an area outside the functional area 12 and is not electrically connected to the functional area 12 .

[0032] Please continue to refer figure 2 As shown, the dummy wiring area 11 is provided with a separation etching line 111 , and the separation etching line divides the dummy wiring area 11 into a plurality of independent floating blocks 112 . The dummy wiring area 11 and the functional area 12 are isolated by the separation etching line 111 ′. Under the conditions of high humidity environment and external electric field, water molecules penetrate into the surface of silver-containing conductor and electrolyze hydrogen ions (H +) and hydroxide ions (OH - ), the silver in the silver-containing conductor wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com