High current inductance

A technology of high current and inductance, applied in the field of inductance, can solve the problem of slow processing speed of inductance, and achieve the effect of improving processing speed and shortening assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

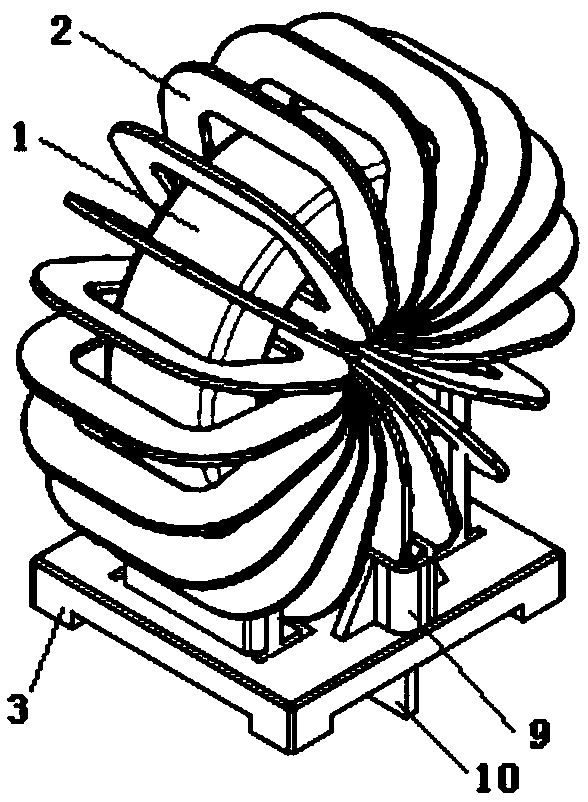

[0028] figure 1 It is the structure diagram of the inductor in Embodiment 1 of the large current inductor of the present invention.

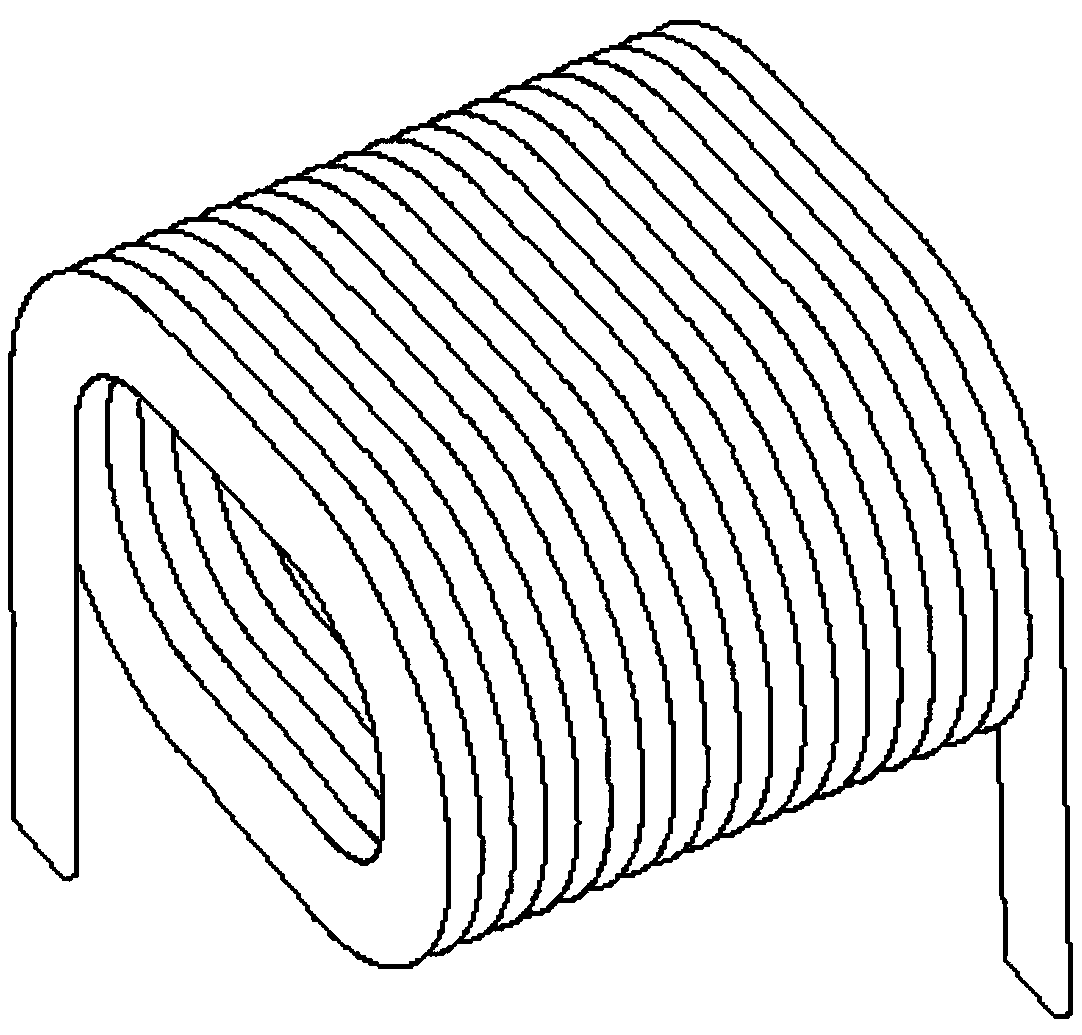

[0029] figure 2 It is a structural diagram of the inductance coil in Embodiment 1 of the large current inductance of the present invention.

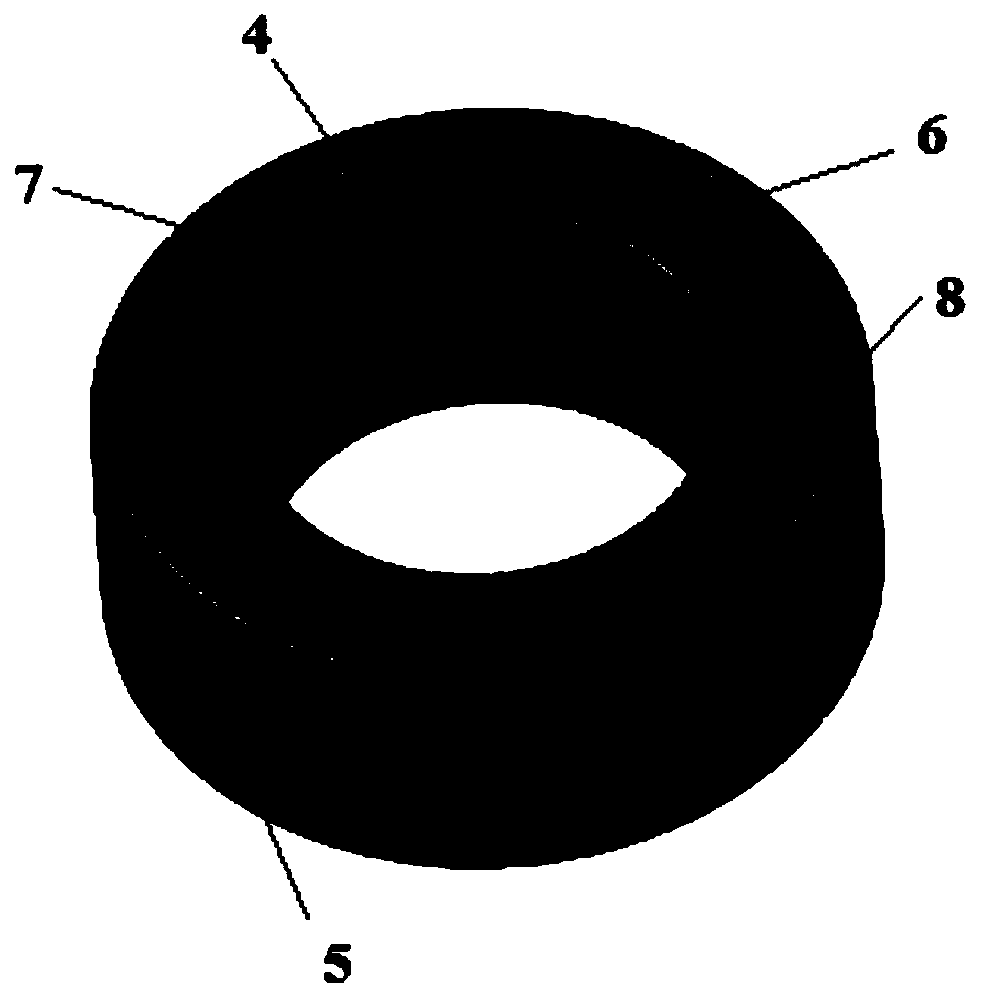

[0030] image 3 It is a structural diagram of the magnetic ring in Embodiment 1 of the large current inductor of the present invention.

[0031] Figure 4 It is a structural diagram of two semicircular magnetic rings in Embodiment 1 of the high-current inductor of the present invention.

[0032] Figure 5 It is an assembly structure diagram of the magnetic ring and the inductance coil in Embodiment 1 of the large current inductor of the present invention.

[0033] Image 6 It is a structural diagram of the fixed base in Embodiment 1 of the high-current inductor of the present invention.

[0034] see Figure 1 to Figure 6 , the high-current inductor includes a magnetic ring set 1 , an inductance c...

Embodiment 2

[0047] Figure 7 It is the structure diagram of the inductor in Embodiment 2 of the large current inductor of the present invention.

[0048] The difference between Embodiment 2 and Embodiment 1 is that the magnetic ring set 1 includes four magnetic rings 4 . The four magnetic rings 4 are arranged in sequence along the axial direction. Due to the increase in the number of magnetic rings 4 , the size of the corresponding inductance coil 2 also increases to match the magnetic ring set 1 . By adjusting the number of the magnetic rings 4, the magnetic rings can satisfy different current inductances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com