Temperature consistency control system and method for power battery of new-energy automobile

A new energy vehicle and power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of battery consistency and life, the lowest temperature of the battery, battery consistency and life, and avoid Uneven temperature distribution, maintain good consistency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

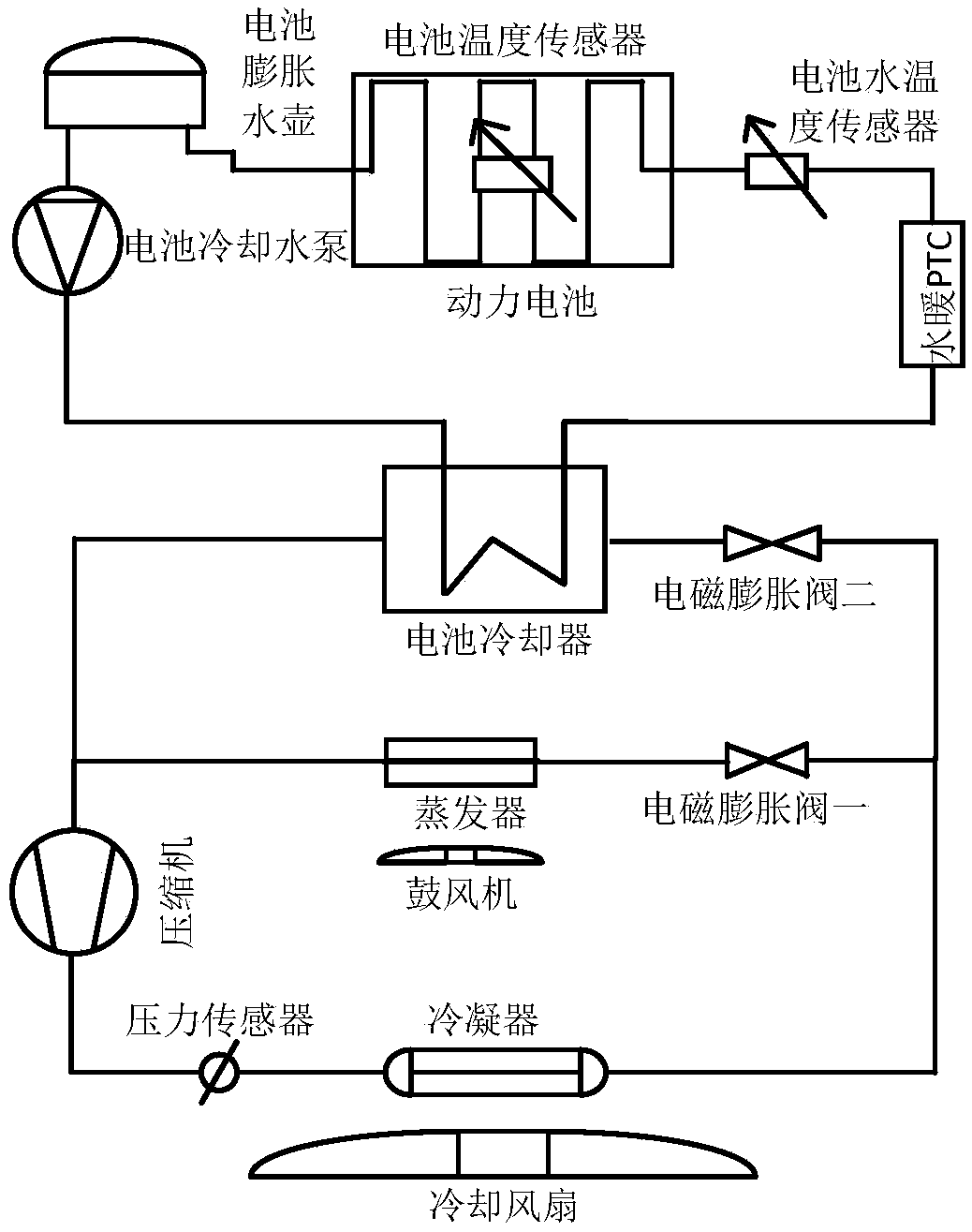

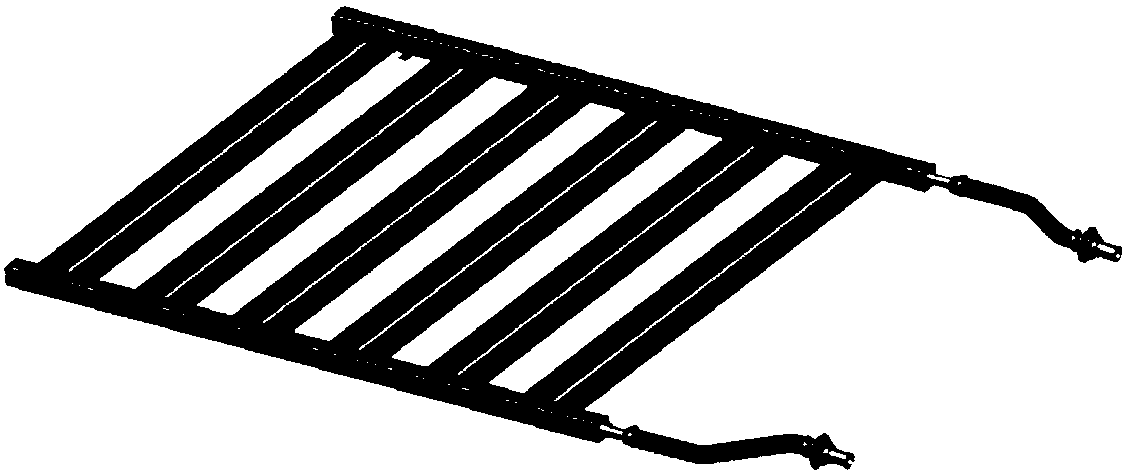

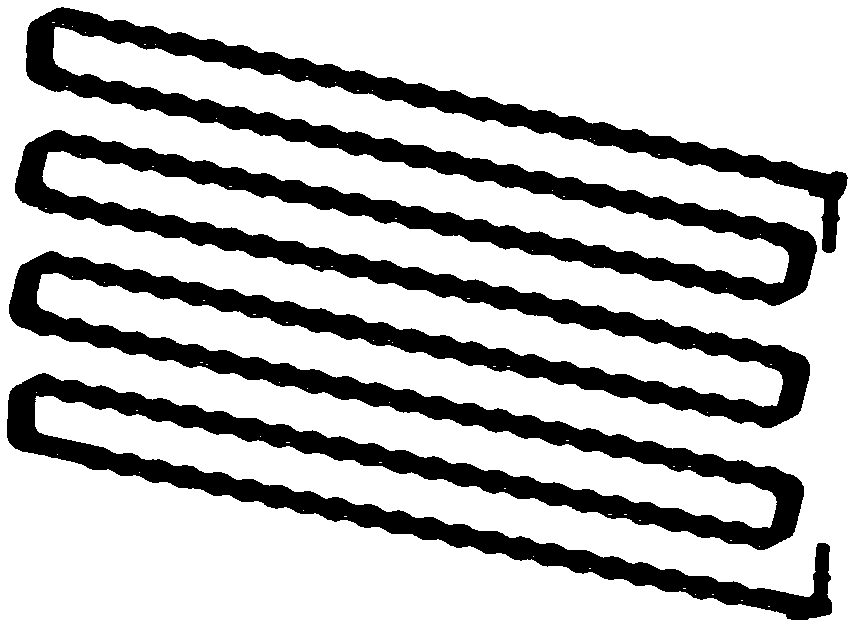

[0030] Such as Figure 5 As shown, a new energy vehicle power battery temperature consistency control system includes a first expansion kettle 5, a first water pump 6, a first three-way water valve 7, and a PTC water heating heater that are sequentially connected to form a battery heating / cooling water circulation loop. 8. The first cooling water temperature sensor 9, the battery cooling plate, the second cooling water temperature sensor 2, the battery cooler 3, the second three-way water valve 4, and the first expansion kettle 5. The battery cooling plate is arranged at the power battery 1 , and the power battery 1 is provided with a plurality of battery temperature sensors 10 respectively connected to the cells inside the power battery 1 . Between the first three-way water valve 7 and the second three-way water valve 4, there is also a circulation branch connected in parallel with the two ends of the series line of the first water pump 6 and the first expansion kettle 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com