Antenna and antenna packaging structure

An antenna and antenna radiator technology, which is applied to the connection of the antenna grounding switch structure, the antenna grounding device, the antenna, etc., can solve the problems of limited and no change in the working mode of the microstrip antenna, and achieve the effect of widening the antenna gain bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

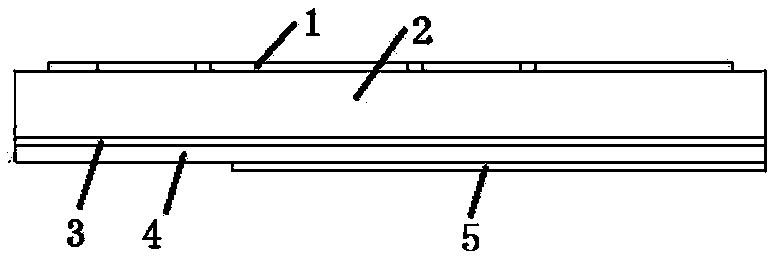

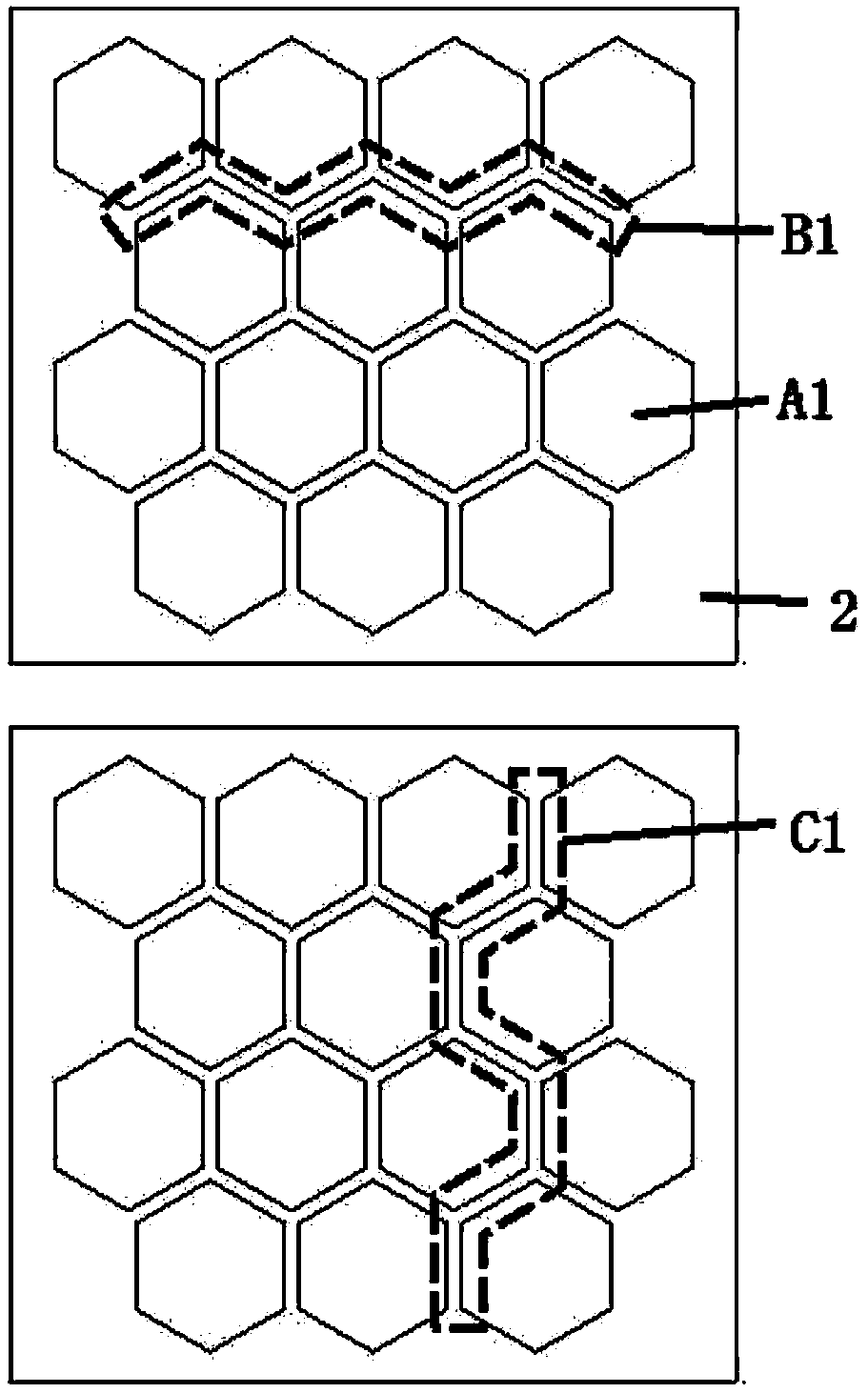

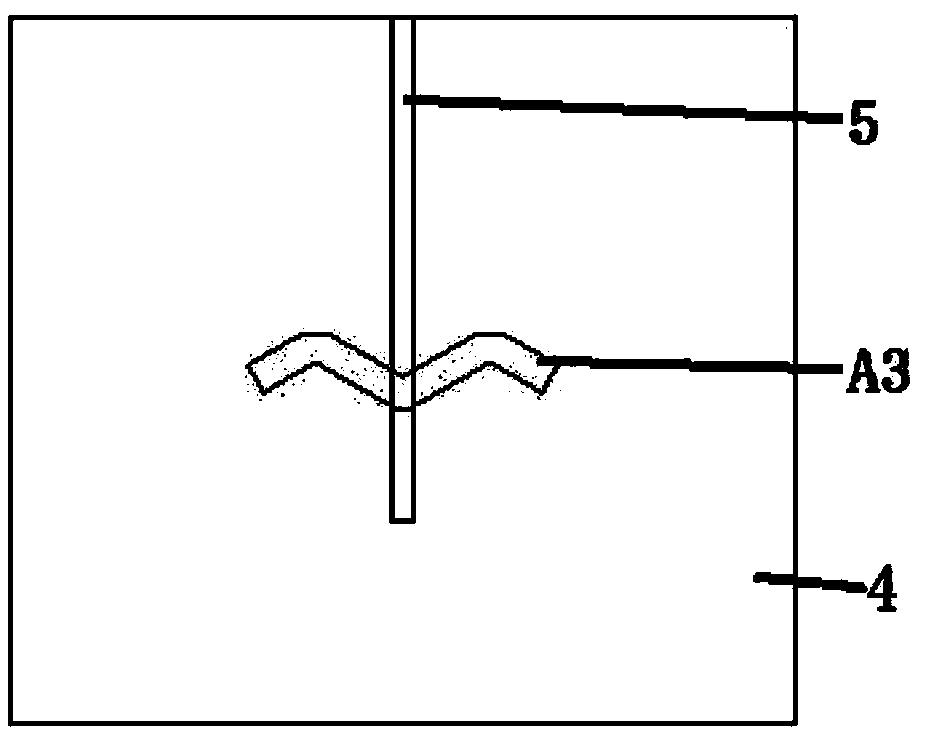

[0058] refer to Figure 1-3 , the antenna radiator is formed by a periodic array of 14 hexagonal metal sheet units A1, the radiation gap B1 formed between adjacent hexagonal metal sheet units in the non-radiation direction and the hexagonal hexagonal blocks in the radiation direction The non-radiative gap C1 formed between the hexagonal metal sheet units makes it form a periodic structure with 14 gaps capacitively loaded, changing the width of the radiation gap and the non-radiative gap formed between adjacent hexagonal metal sheet units can improve the performance of the antenna bandwidth. image 3 It is the schematic diagram of the back side of the antenna. The feeding form of the antenna adopts the slot coupling feeding form. There is a W-shaped feeding slot in the center of the grounded metal plate. The microstrip feeder couples the electromagnetic energy to the antenna radiator through the W-shaped feeding slot. By adjusting the micro With feeder stub length to improve i...

Embodiment 2

[0061] refer to Figure 4 , this embodiment is similar to Embodiment 1, but the arrangement of the antenna radiator is changed. The antenna radiator is composed of 10 hexagonal metal sheet units and 4 semi-hexagonal metal sheet units. Cut off half of the polygonal element, and the size of the non-radiating side of the antenna becomes smaller.

Embodiment 3

[0063] refer to Figure 5 , this embodiment is similar to Embodiment 1, the difference is that the center of each hexagonal metal sheet unit is loaded with a metal via D1 connected to the ground metal plate, the radiation slot and the non-radiation slot and the metal via hole make each Parallel capacitance and series inductance are formed between metal sheet units, and the gap formed between adjacent metal sheets along the direction of the feeder will generate electromagnetic radiation, which excites two modes, TM10 and TM20, to form broadband characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com