Shaft voltage reduction structure and plastic packaging motor equipped with shaft voltage reduction structure

A shaft voltage and electrical connection technology, which is applied in structural connection, electrical components, electromechanical devices, etc., can solve problems such as voltage overshoot of the inner and outer rings of the bearing, electric corrosion of the inner and outer rings and balls, breakdown of the oil film of the bearing raceway, etc., to ensure The effect of motor life and reliability, reduction of electric corrosion risk, and wide application of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

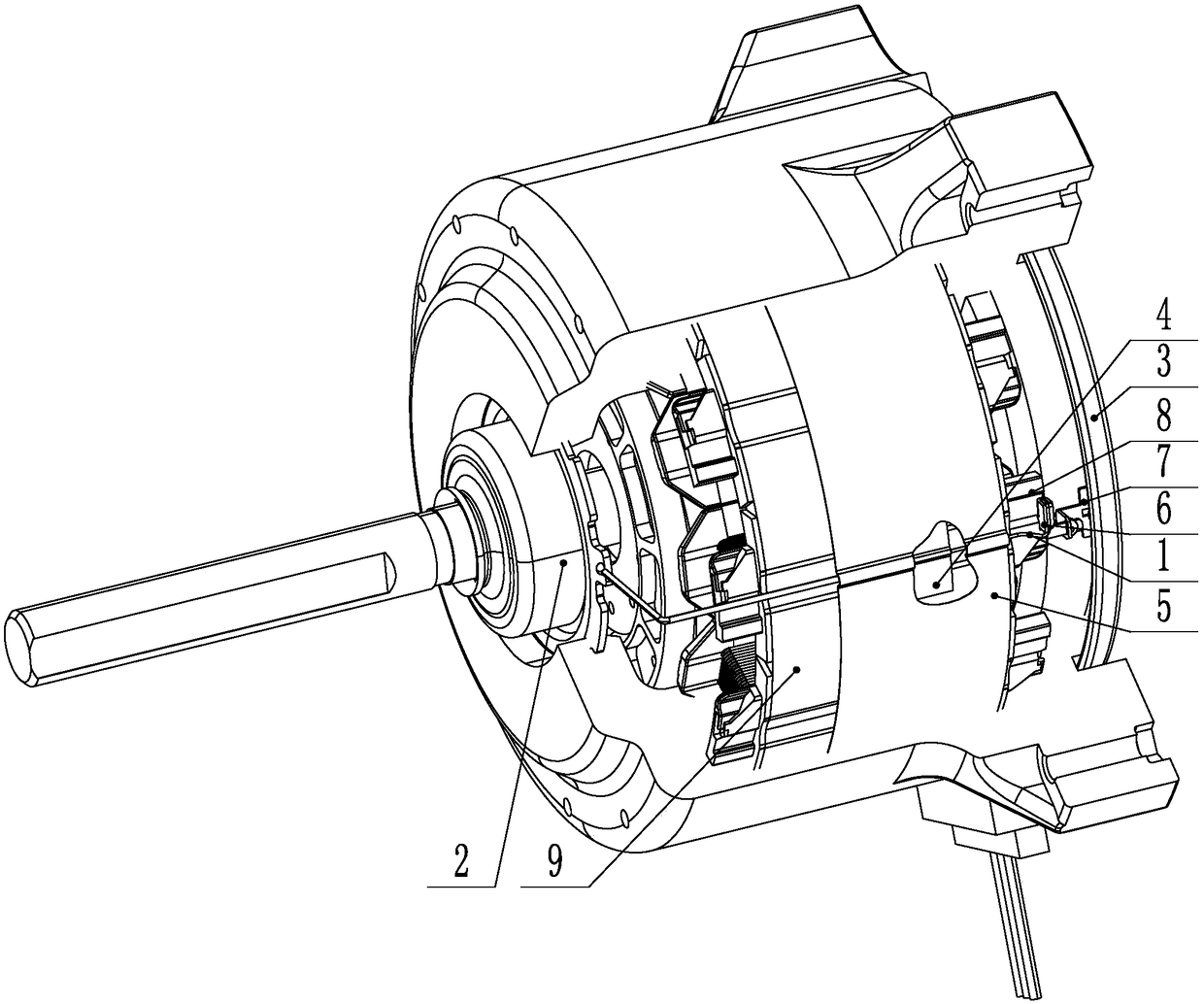

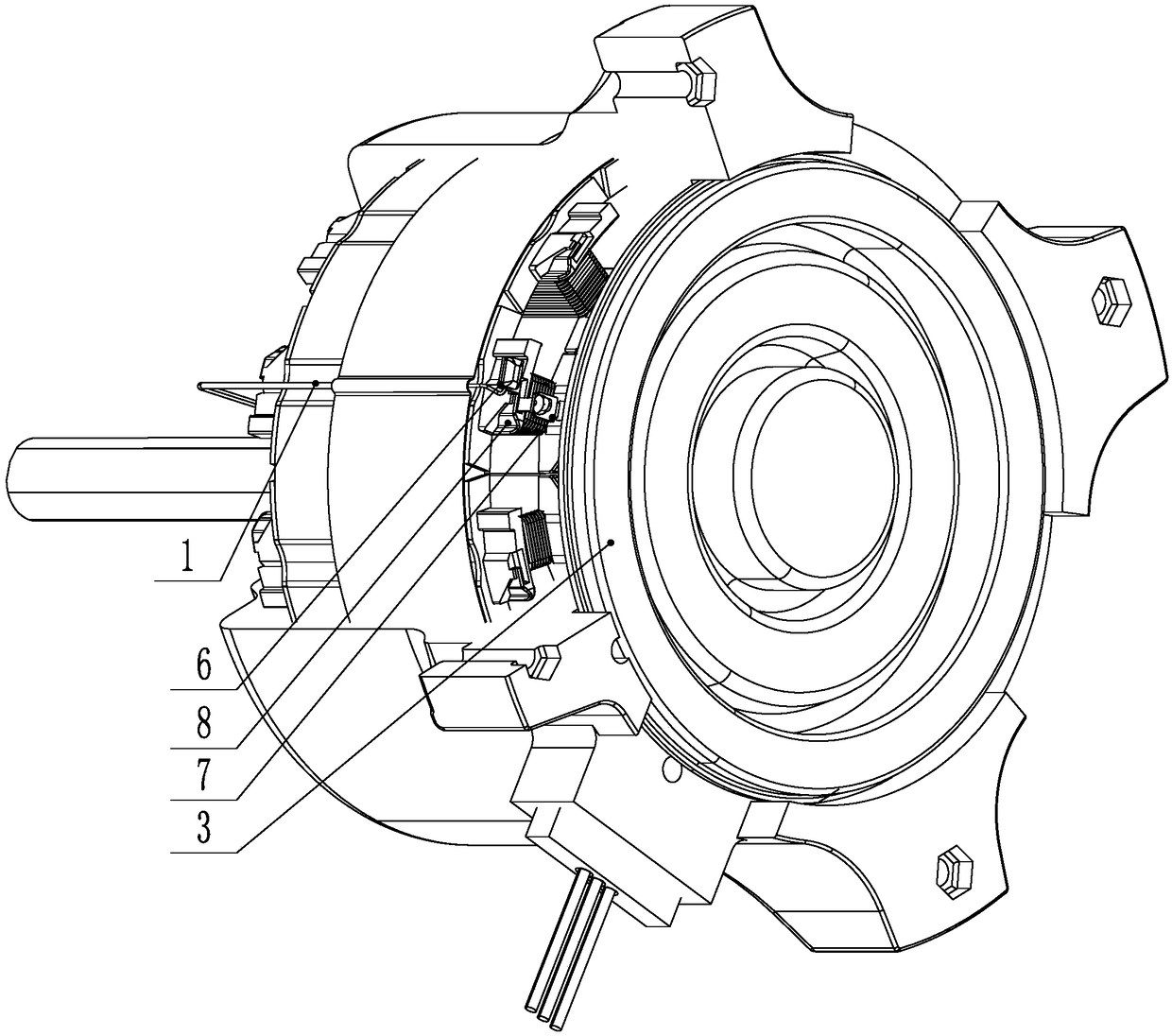

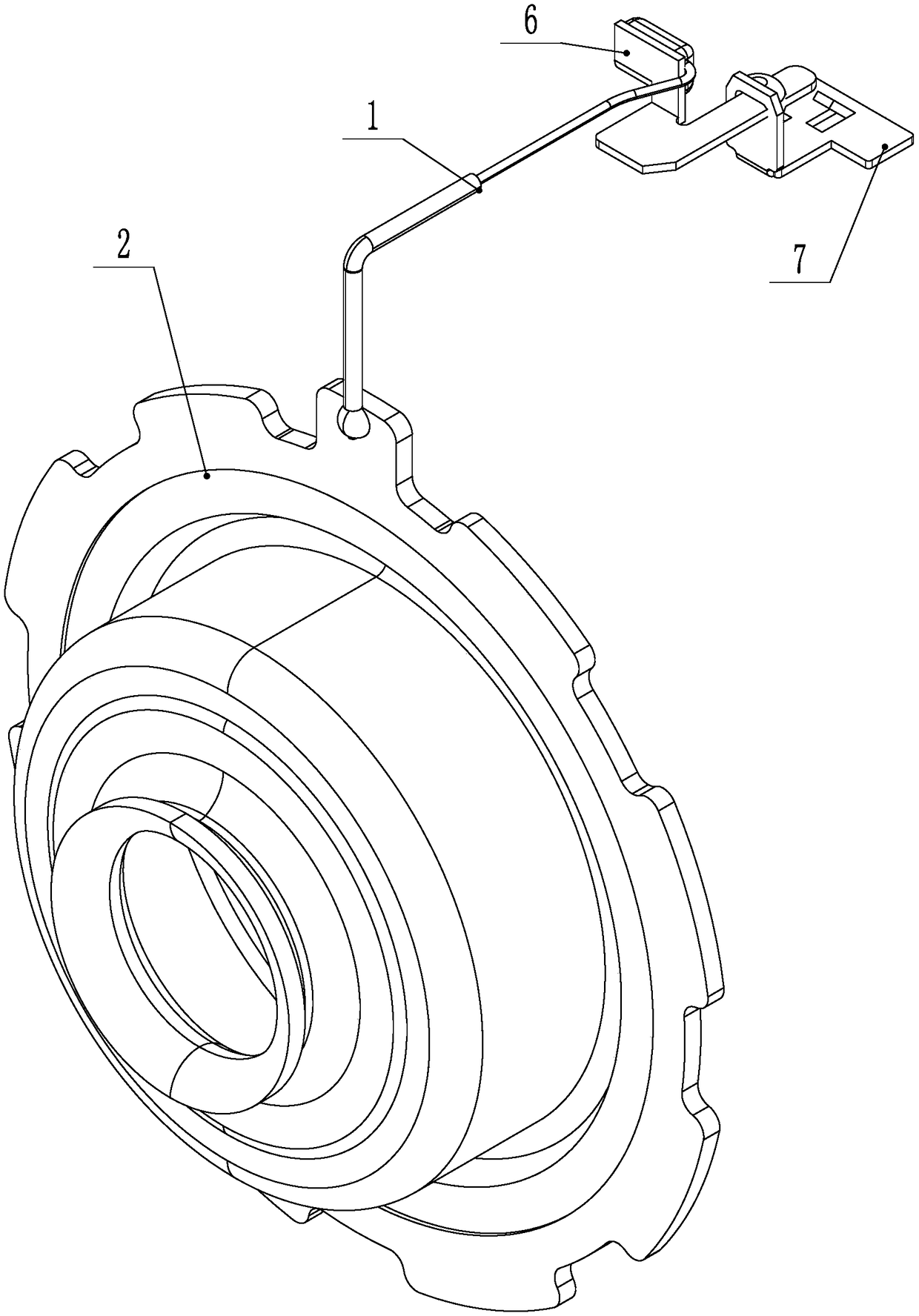

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] A structure for reducing shaft voltage, including a wire 1, a stator core electrical connector, and an end cover electrical connector; the first end of the wire 1 is electrically connected to the first end cover 2, and the wire 1 is electrically connected through the stator core The wire 1 is electrically connected with the stator core 9, and the second end of the wire 1 is electrically connected with the second end cover 3 through the end cover electrical connector arranged on the insulating frame 8, so that the first end cover 2, the stator iron core The core 9 and the second end cap 3 are in an equipotential state. Through the above-mentioned structure, this technical solution makes the end covers on both sides effectively conduct with the stator core 9, forms equipotentials, and greatly reduces the shaft voltage, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com