PCB secondary and multiple accurate punching method based on visual tracking

A PCB board and visual tracking technology, which is applied in the direction of circuit board tool positioning, electrical components, printed circuit manufacturing, etc., can solve the problems of insufficient precision of PCB board punching technology, unsuitable printed plugs, etc., to facilitate extraction and Positioning, image background interference is less, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0027] For some English abbreviations covered in the present invention, the next paragraph focuses on the meaning of these English abbreviations.

[0028] For example: the Mark point of the PCB board is the position recognition point of the PCB board applied to the automatic placement machine in the circuit board design, also called a mark point or a feature point; it is the overall shape of an image target, described by a high-order moment feature vector is the detail of the image target.

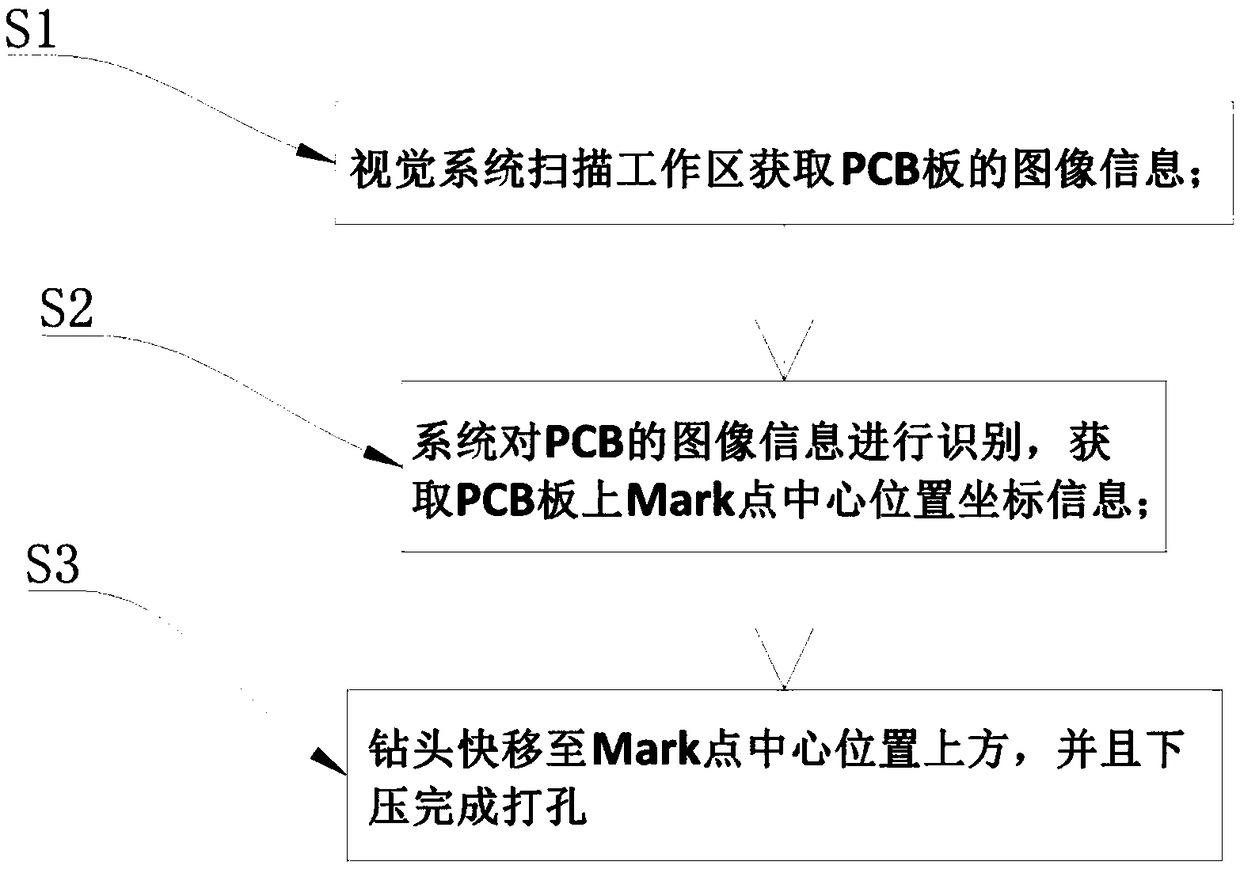

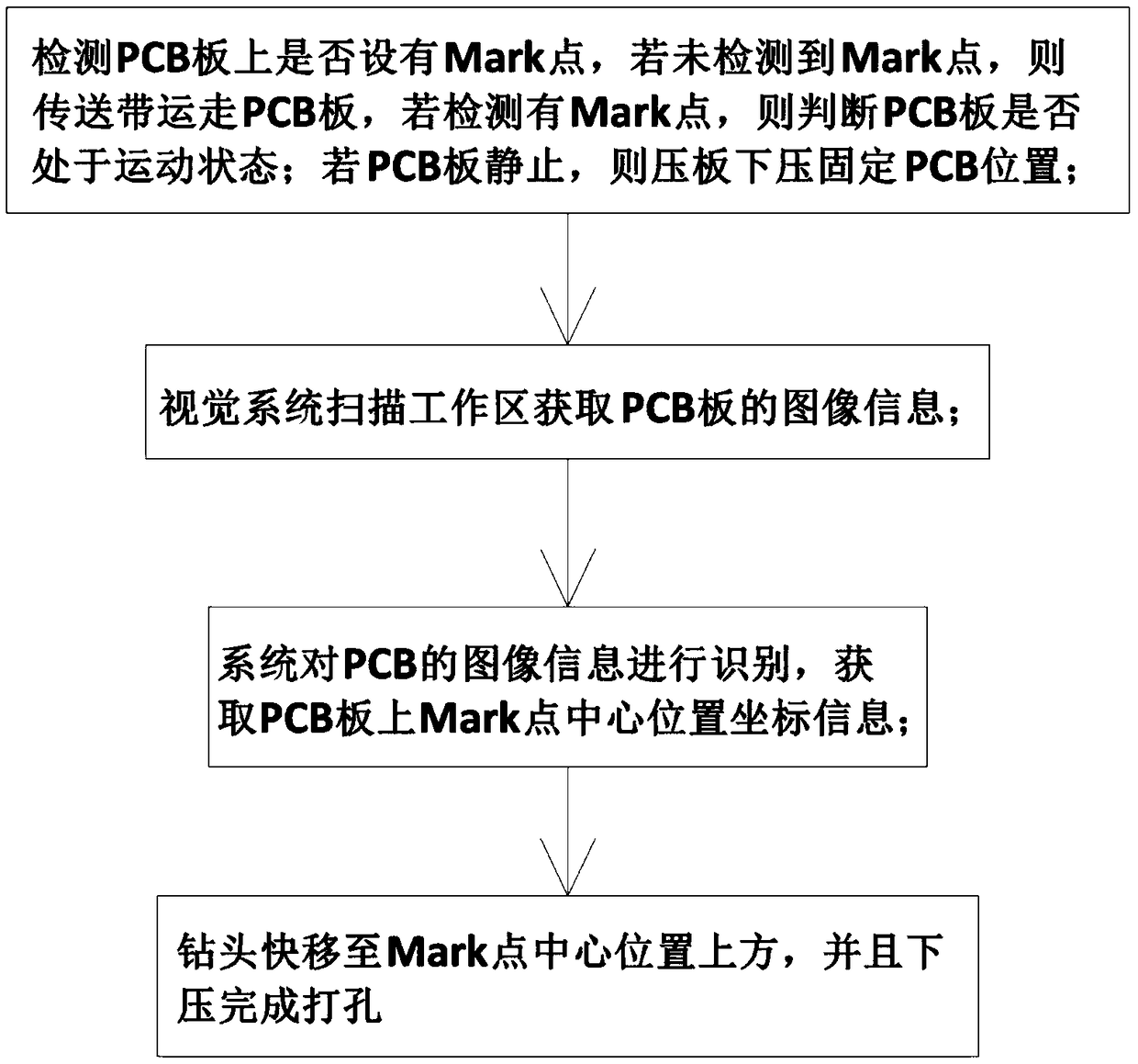

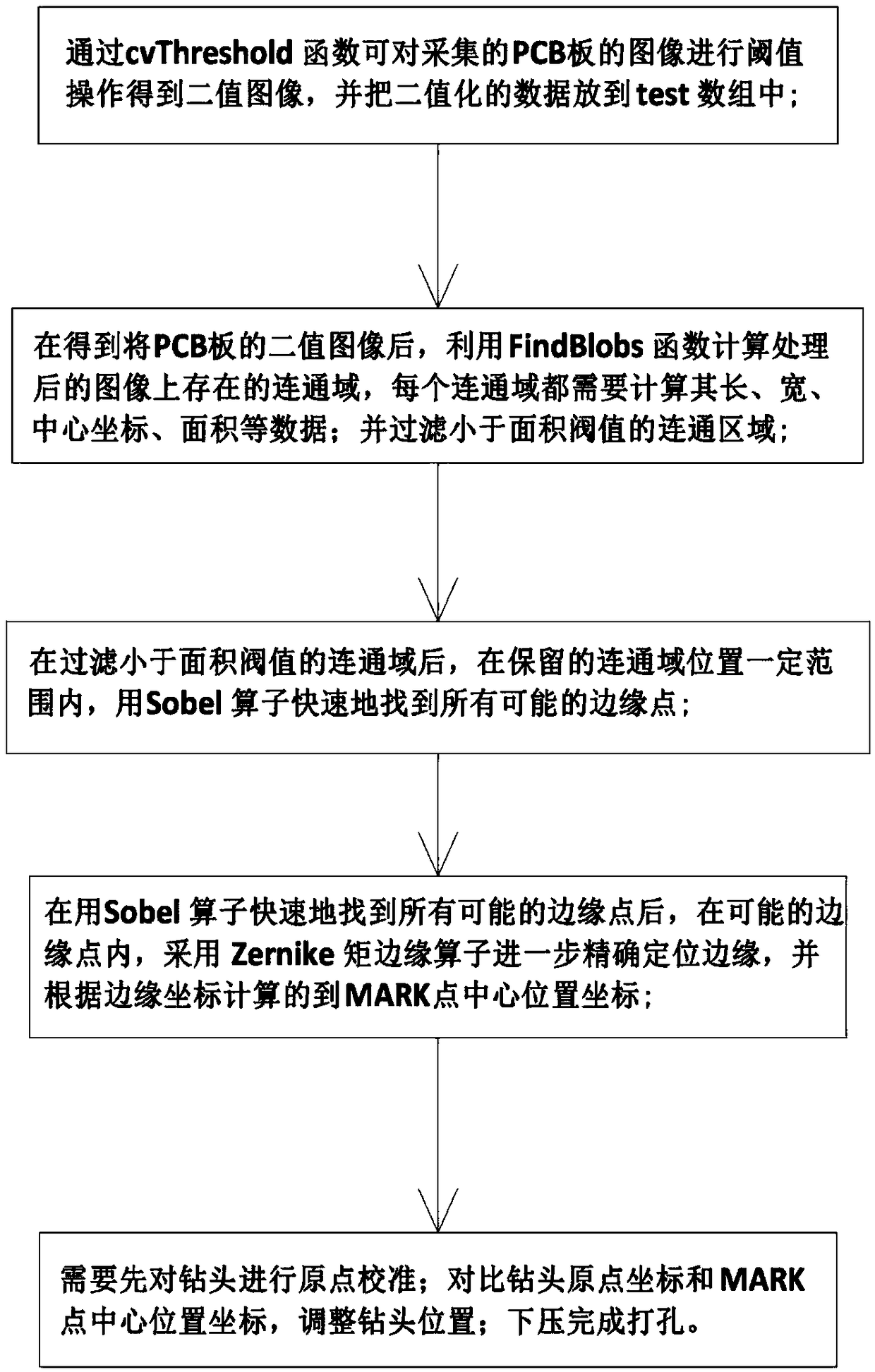

[0029] see figure 1 , the present invention takes the processing process as an example, and specifically illustrates the PCB board punching method utilizing Mark point positioning, specifically comprising the following steps:

[0030] S1: Put the PCB board to be tested on the acquisition surface of the vision system, select ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com