Upper feeding and covering device for color covered household appliance product paint covering and covering method thereof

A technology for home appliances and coating devices, which is applied to devices and coatings that apply liquid to surfaces, and can solve problems such as affecting production rhythm, increasing waste, and short strips, so as to prevent local bright or short strips. strips, improve uniformity and fineness, and ensure the effect of lateral uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

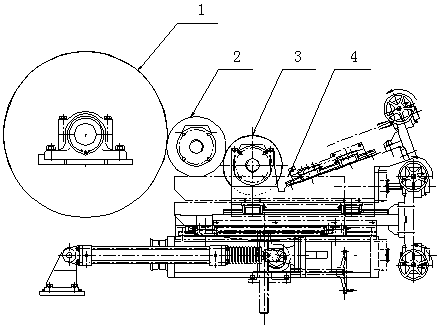

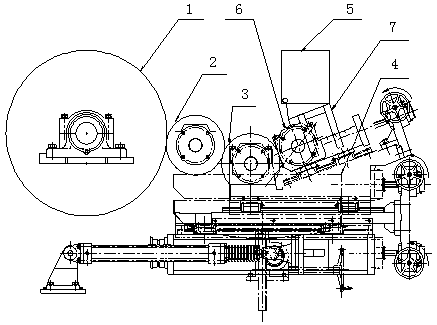

[0024] In this example, refer to the attached figure 2 , a feeding and coating device for color-coated household appliances, including a support roller 1, a coating roller 2, a dipping roller 3, a feeding tray 5, a metering roller 6 and a support frame 7, and the metering roller 6 is positioned at the dipping roller Obliquely above the roller 3, the height difference between the metering roller 6 and the dipping roller 3 is controlled at 15-18cm. The purpose is to prolong the leveling time of the paint on the metering roller 6 and ensure that the paint is evenly leveled on the metering roller 6. sex.

[0025] The feeding tray 5 above the metering roller 6 is made of stainless steel and has a size of 300*300*300mm. Both ends of the feeding tray 5 are provided with a discharge port, which is located directly above the metering roller 6. The feeding tray 5 is fixed on the support frame 7 .

[0026] The material used for the support frame 7 is 3# angle steel with a span of 2270...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com