CNC online cleaning device

A technology for cleaning devices and dust suction ports, which is used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. and other problems, to avoid the inconvenience of processing, eliminate the pollution of the production environment, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

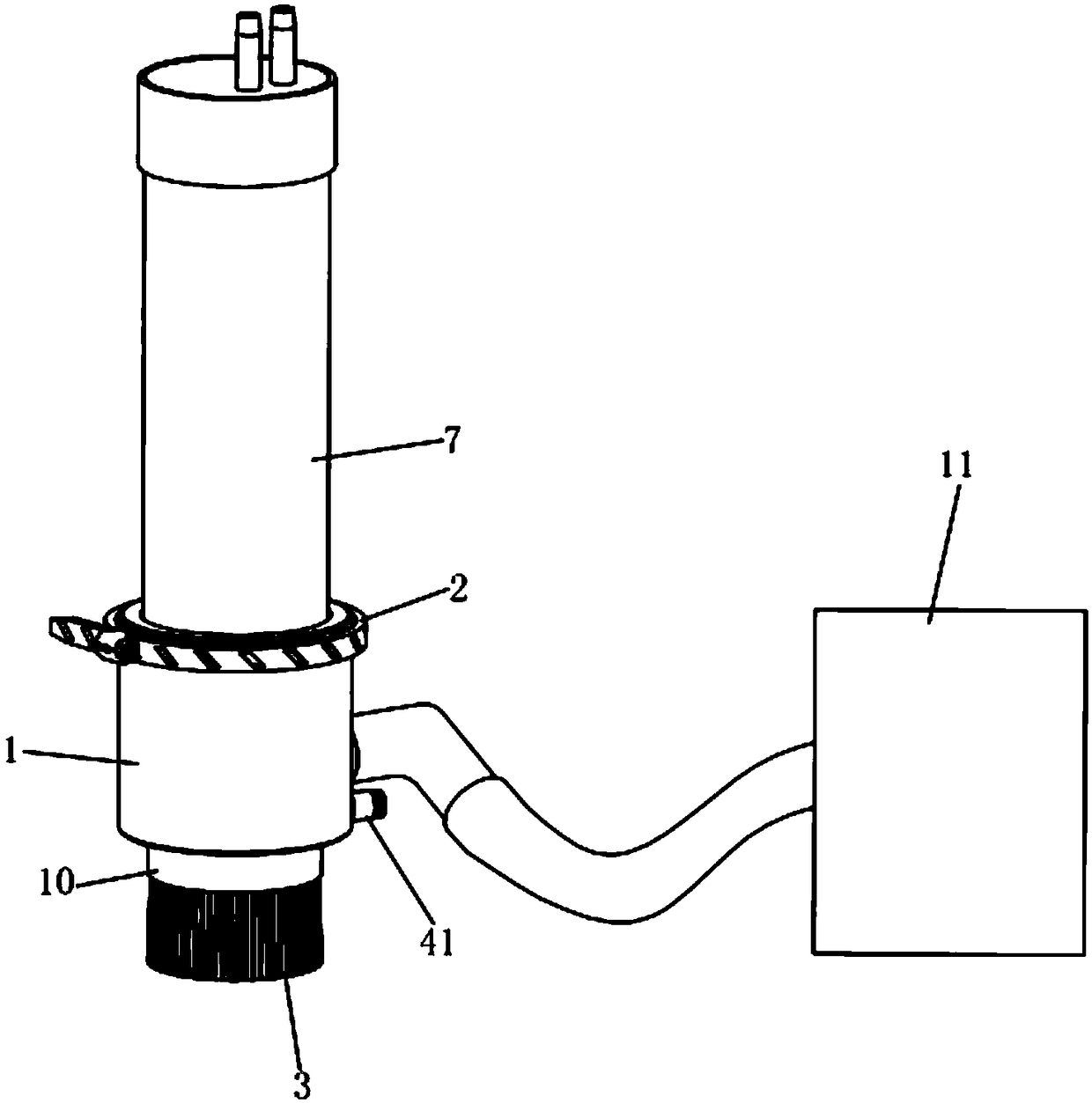

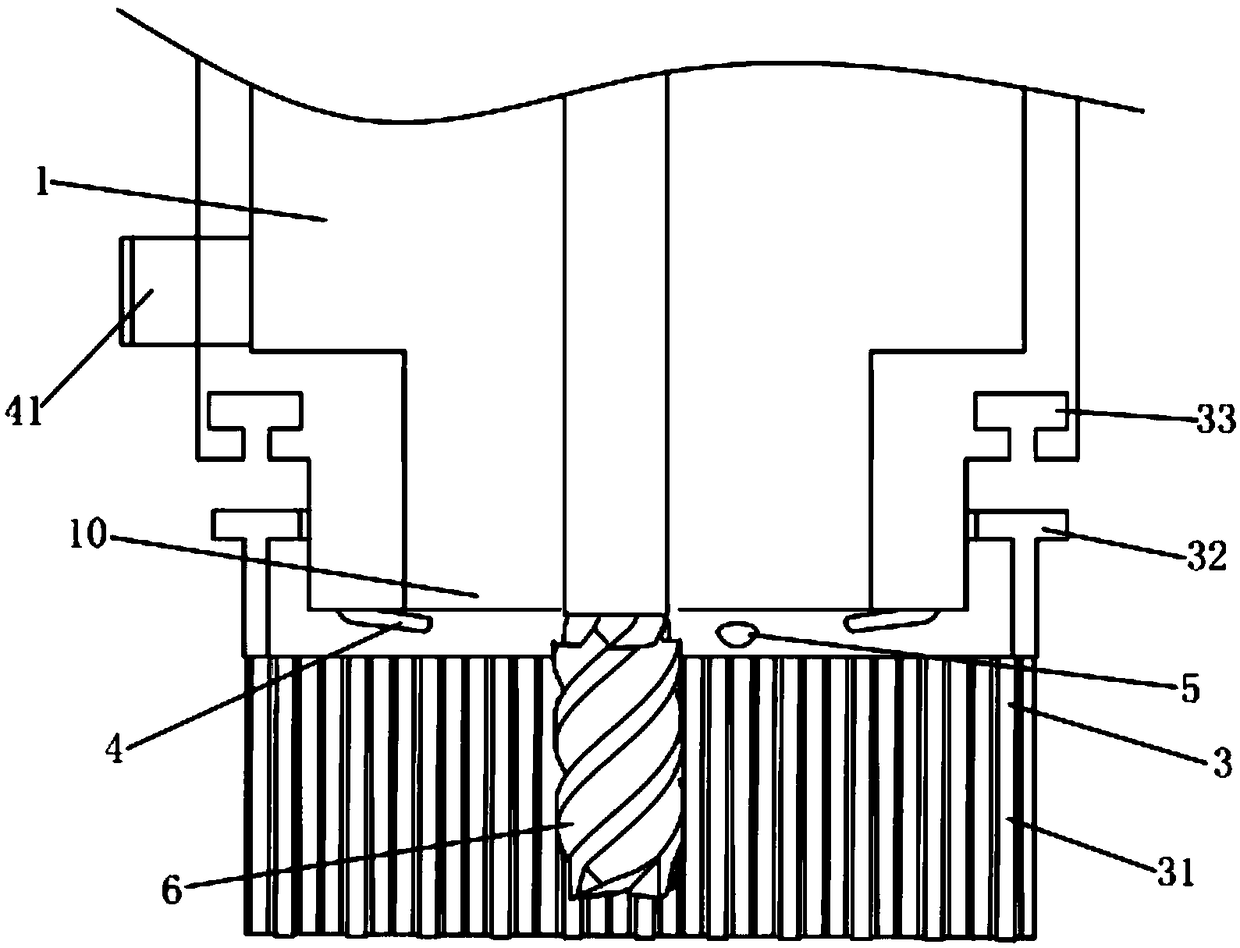

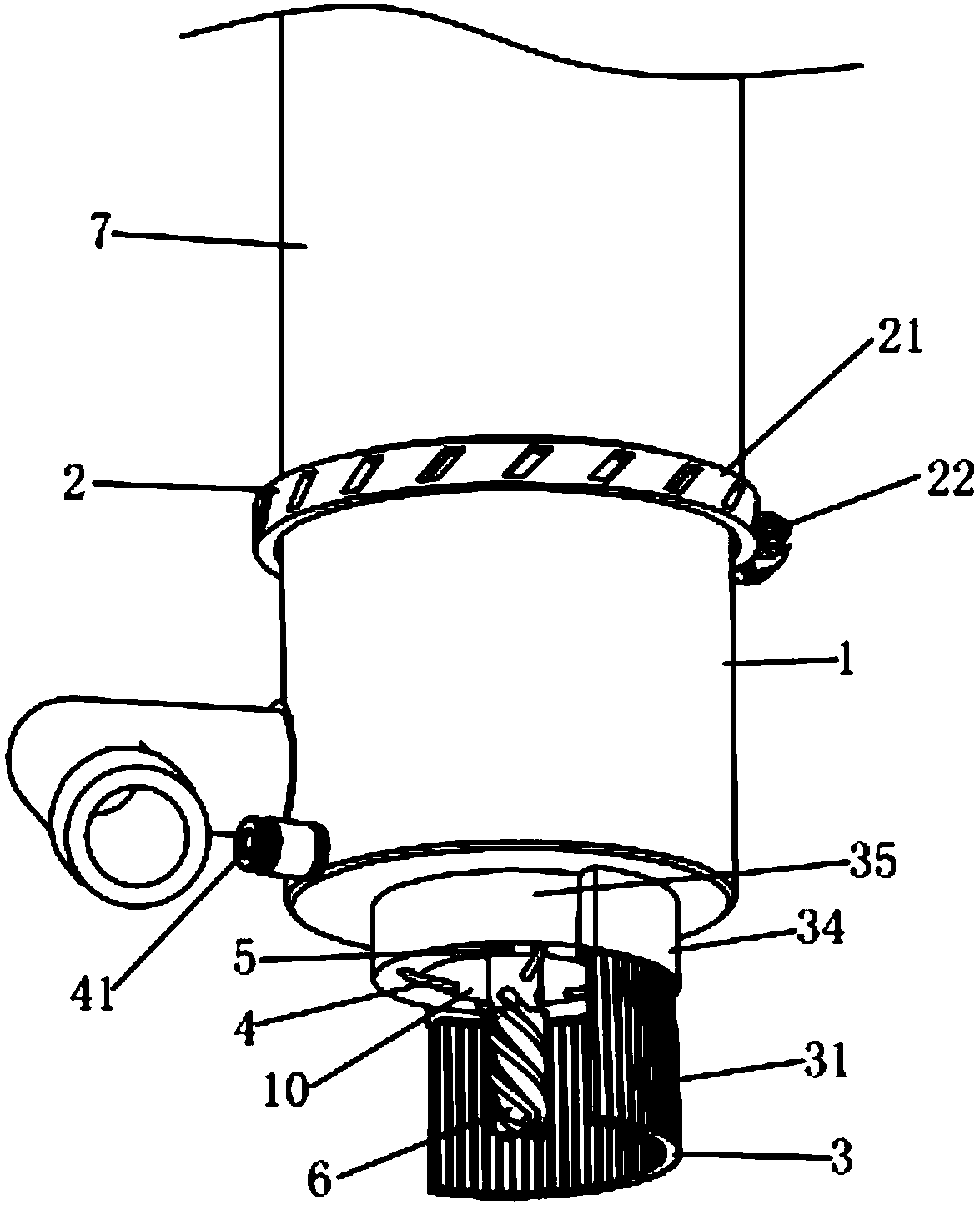

[0026] Embodiment one: if figure 1 and figure 2 As shown, a CNC online cleaning device includes: a high-speed dust suction chamber 1 arranged at the end of the high-speed motor 7 close to the processing cutter head 6; 10; an explosion-proof vacuum cleaner 11 connected to the high-speed dust collection chamber 1; a locking assembly 2 for connecting the high-speed dust collection chamber 1 to the high-speed motor 7; and a barrier assembly arranged on the side of the suction port 10 3. Under the action of the explosion-proof vacuum cleaner 11, the dust suction port 10 absorbs the dust generated at one end of the processing cutter head 6, and the absorbed dust is collected in the explosion-proof vacuum cleaner 11 through the high-speed dust suction chamber 1, and at the same time, the components are blocked 3. It is used to prevent the dust generated at one end of the processing cutter head 6 from scattering, so as to ensure that the dust suction port 10 has a better dust absorp...

Embodiment 2

[0031]Embodiment 2: A CNC online cleaning device, comprising: a high-speed dust suction chamber 1 arranged at the end of the high-speed motor 7 close to the processing cutter head 6; Port 10; an explosion-proof vacuum cleaner 11 connected to the high-speed dust collection chamber 1; a locking assembly 2 for connecting the high-speed dust collection chamber 1 to the high-speed motor 7; and a barrier arranged on the side of the suction port 10 Component 3, under the action of the explosion-proof vacuum cleaner 11, the dust suction port 10 absorbs the dust generated at one end of the processing cutter head 6, and the absorbed dust is collected in the explosion-proof vacuum cleaner 11 through the high-speed dust suction chamber 1, and at the same time, the The component 3 is used to prevent the dust generated at one end of the processing cutter head 6 from spreading out, so as to ensure that the dust suction port 10 has a better dust absorption effect.

[0032] The difference betw...

Embodiment 3

[0033] Embodiment 3: A CNC online cleaning device, including: a high-speed dust collection chamber 1 arranged at the end of the high-speed motor 7 close to the processing cutter head 6; Port 10; an explosion-proof vacuum cleaner 11 connected to the high-speed dust collection chamber 1; a locking assembly 2 for connecting the high-speed dust collection chamber 1 to the high-speed motor 7; and a barrier arranged on the side of the suction port 10 Component 3, under the action of the explosion-proof vacuum cleaner 11, the dust suction port 10 absorbs the dust generated at one end of the processing cutter head 6, and the absorbed dust is collected in the explosion-proof vacuum cleaner 11 through the high-speed dust suction chamber 1, and at the same time, the The component 3 is used to prevent the dust generated at one end of the processing cutter head 6 from spreading out, so as to ensure that the dust suction port 10 has a better dust absorption effect.

[0034] The difference b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com