Real-time obstacle avoidance planning and grasping system of industrial manipulator based on kinect depth camera

A technology of depth camera and industrial machinery, which is applied in the field of real-time obstacle avoidance planning and grasping system of industrial manipulator, can solve the problems of low intelligence and low structural integration, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with specific examples.

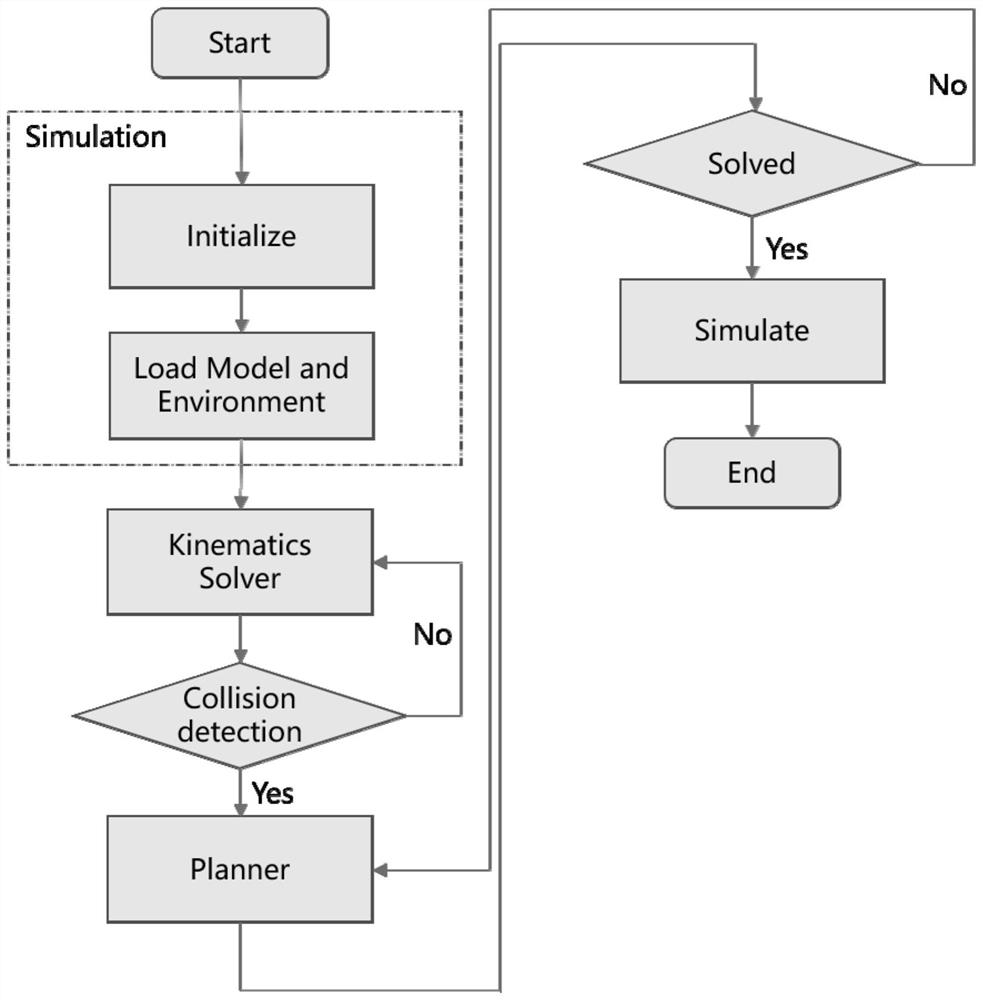

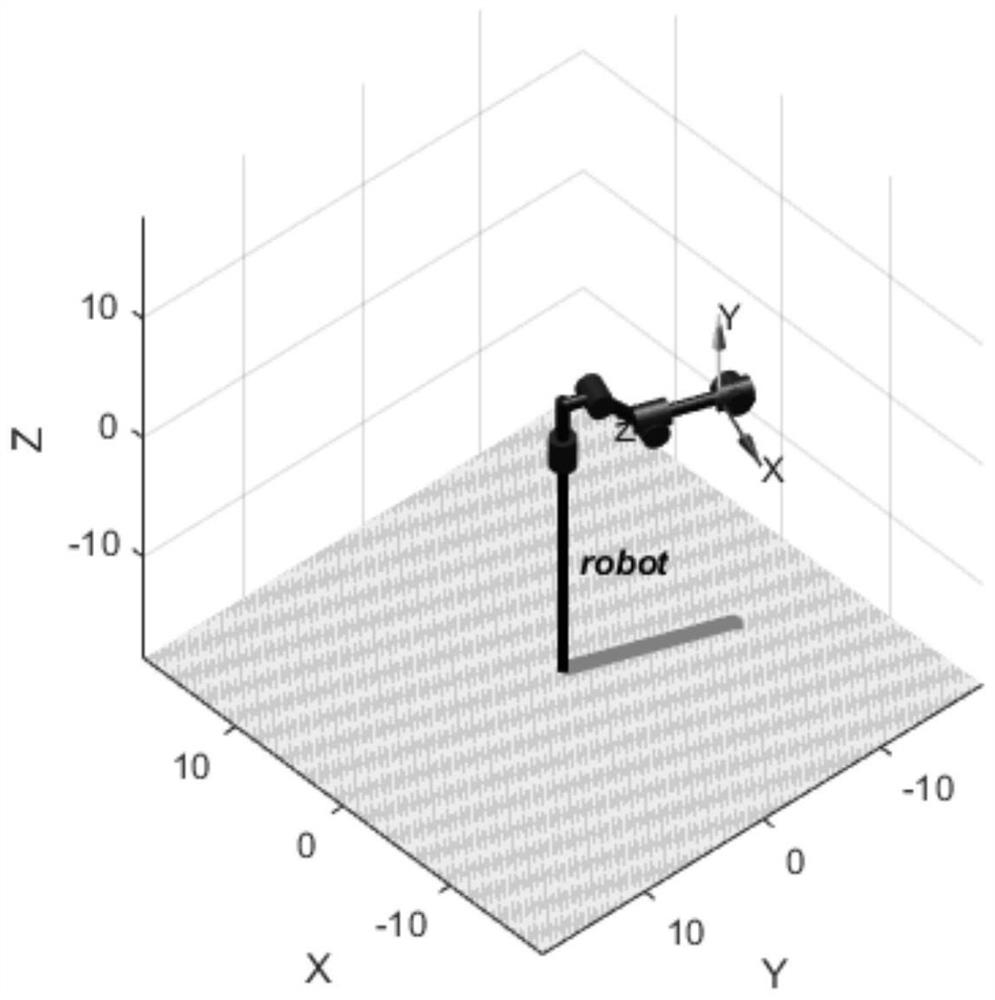

[0056] The real-time obstacle avoidance planning and grasping system of the industrial manipulator based on the Kinect depth camera provided by the present invention specifically combines computer vision and digital image processing technology to sense the position and size of dynamic obstacles in the working space of the industrial manipulator through the Kinect camera Information, and then use the path planning algorithm for path planning. After the optimal path is calculated, the robotic arm is driven to achieve the optimal grasping pose, and then the dexterous hand is controlled by the 5DT data glove to carry out the grasping operation.

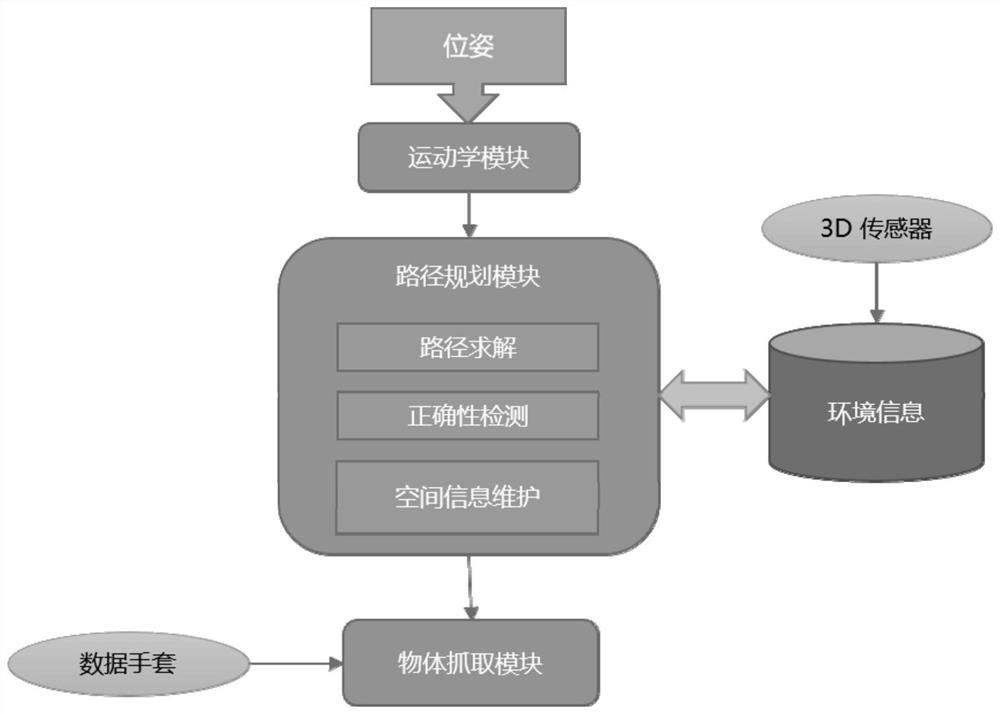

[0057] System architecture such as figure 1 As shown, it consists of five parts: kinematics module, path planning module, object grasping module, dynamic environment detection module and simulation module. The five modules complement ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com