Method for extruding and molding bimodal polyethylene product

A bimodal polyethylene extrusion molding technology, which is applied in the field of extrusion molding of high-strength branched bimodal polyethylene products, can solve the problems of insufficient mechanical properties of bimodal polyethylene products, so as to promote formation and increase stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

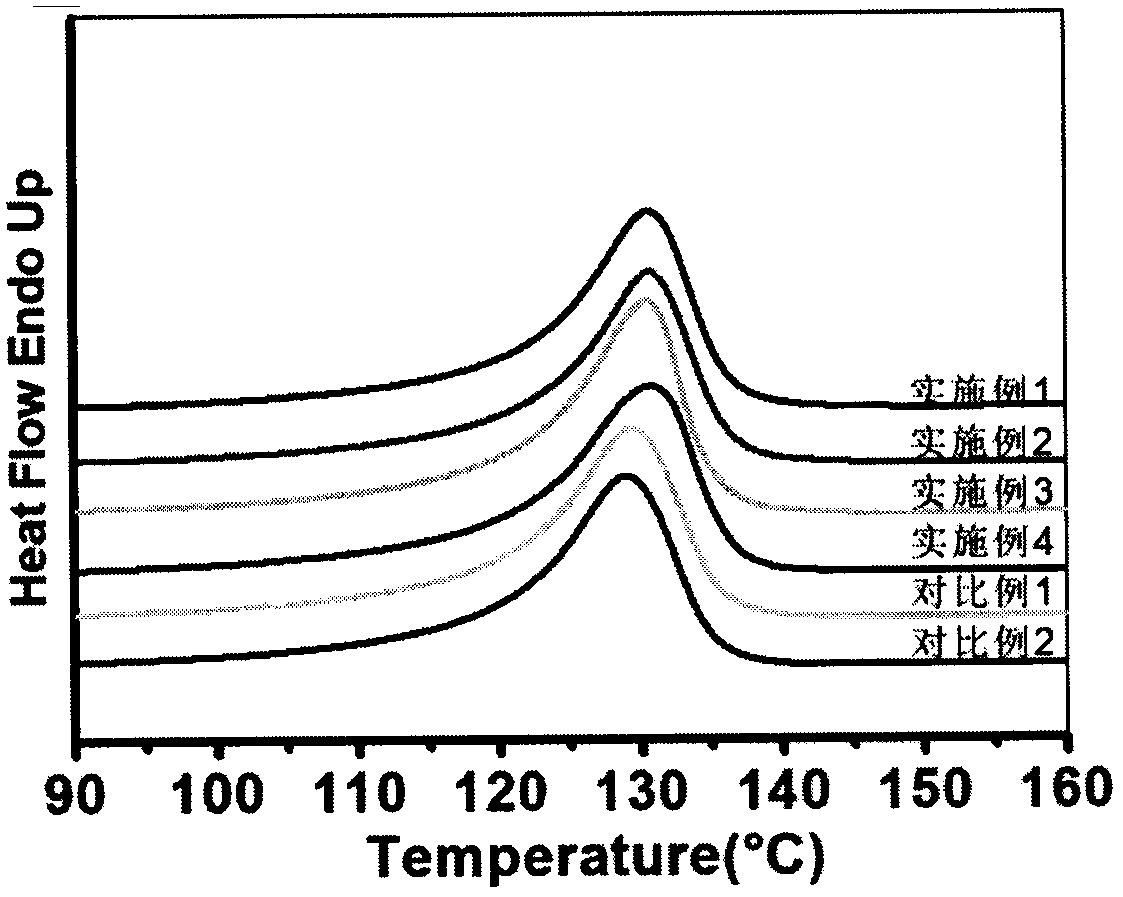

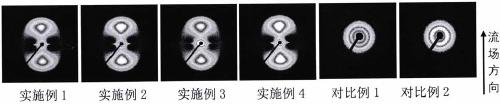

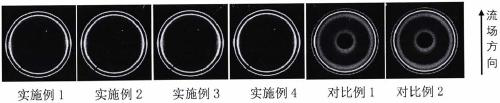

[0033] Add 1000g of bimodal polyethylene with a weight average molecular weight of 210000 and a molecular weight distribution of 24, 1250mg of antioxidant 1010, and 1000mg of lubricant into a single-screw extruder to obtain bimodal polyethylene products, wherein the bimodal polyethylene is high The mass content of the molecular weight part is 10%, the weight average molecular weight is 820,000, and the molecular weight distribution is 3. The high molecular weight part contains 60 ethyl branched chains for every 10,000 carbon atoms; the mass content of the low molecular weight part of bimodal polyethylene is 90%. The average molecular weight is 170,000, and the molecular weight distribution is 4; the temperature of the feed section of the extruder is 120°C, the temperature of the compression section is 165°C, the temperature of the homogenization section is 160°C, and the temperature of the die is 160°C. The section is conical, the speed of the material passing through the die i...

Embodiment 2

[0035] Add 1,000g of bimodal polyethylene with a weight average molecular weight of 350,000 and a molecular weight distribution of 35, 800mg of antioxidant 1076, and 600mg of flame retardant into a single-screw extruder to obtain bimodal polyethylene products, wherein bimodal polyethylene The mass content of the high molecular weight part is 30%, the weight average molecular weight is 1,000,000, and the molecular weight distribution is 5. The high molecular weight part contains 30 butyl branches per 10,000 carbon atoms; the mass content of the bimodal polyethylene low molecular weight part is 70%, The weight-average molecular weight is 60,000, and the molecular weight distribution is 5; the temperature of the feed section of the extruder is 130°C, the temperature of the compression section is 180°C, the temperature of the homogenization section is 180°C, and the temperature of the die is 200°C. The flow section is conical, the speed of the material passing through the die is 30...

Embodiment 3

[0037] Add 1,000g of bimodal polyethylene with a weight average molecular weight of 500,000 and a molecular weight distribution of 47 and 900mg of antioxidant 168 into a single-screw extruder and extrude to obtain a bimodal polyethylene product, wherein the high molecular weight part of bimodal polyethylene has a mass content of The weight average molecular weight is 1,200,000, the molecular weight distribution is 7, and the high molecular weight part contains 20 hexyl branched chains per 10,000 carbon atoms; the mass content of the bimodal polyethylene low molecular weight part is 58%, and the weight average molecular weight is 20,000, The molecular weight distribution is 8; the temperature of the feed section of the extruder is 140°C, the temperature of the compression section is 218°C, the temperature of the homogenization section is 216°C, and the temperature of the die is 220°C, and the diversion section of the extruder is a semi-single lobe Hyperboloid shape, the speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com