A Tempered Glass Homogenizing Furnace

A tempered glass and homogenizing furnace technology, applied in the field of tempered glass homogenizing furnace, can solve the problems of low processing efficiency in the tempered glass homogenizing process, achieve the effects of shortening the processing cycle time, increasing the homogenizing speed, and eliminating heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

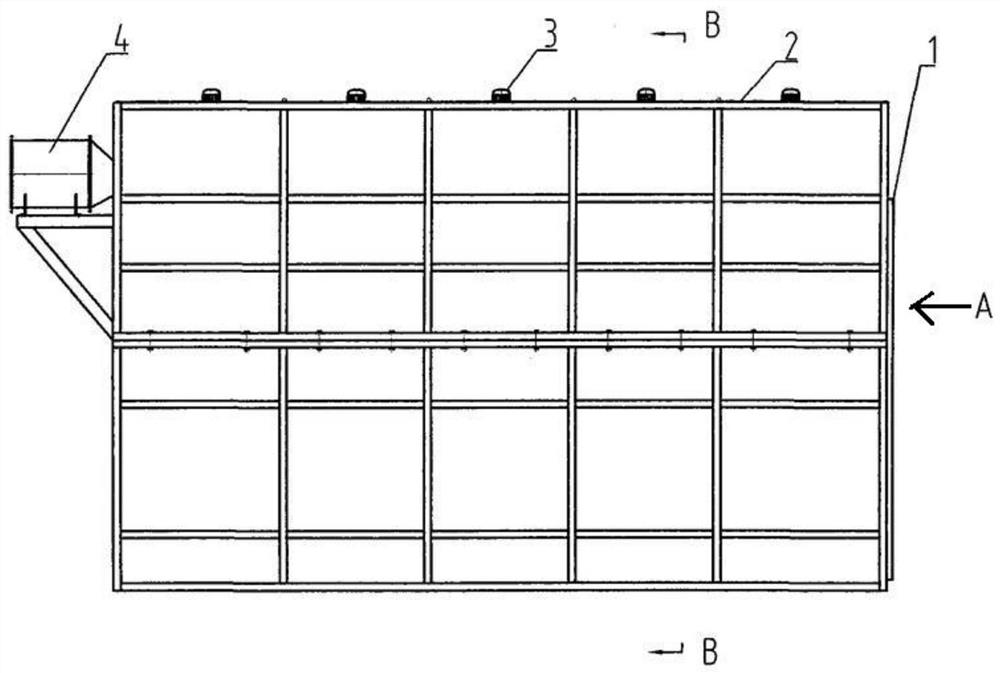

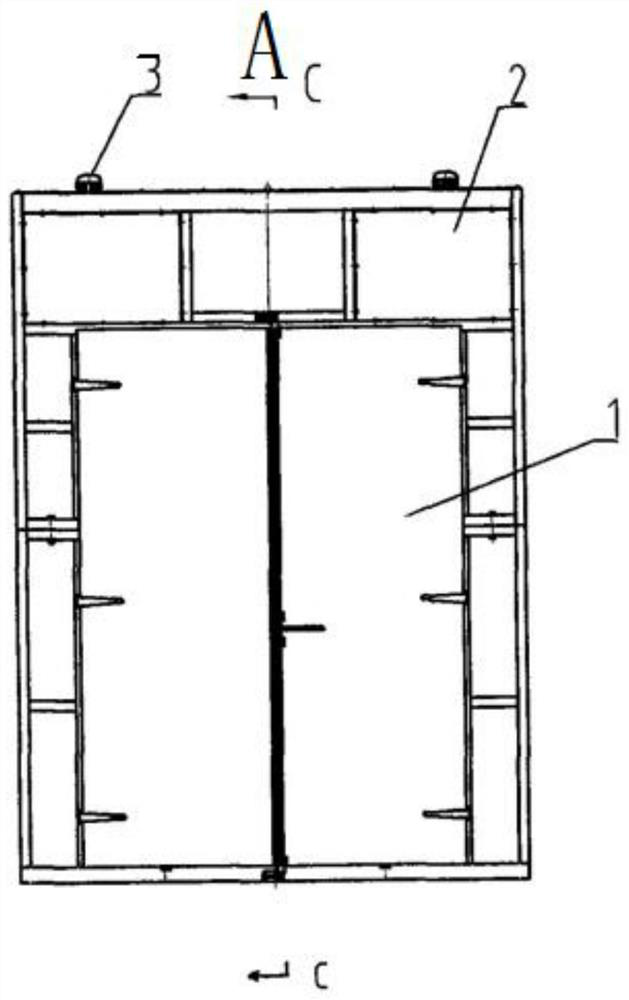

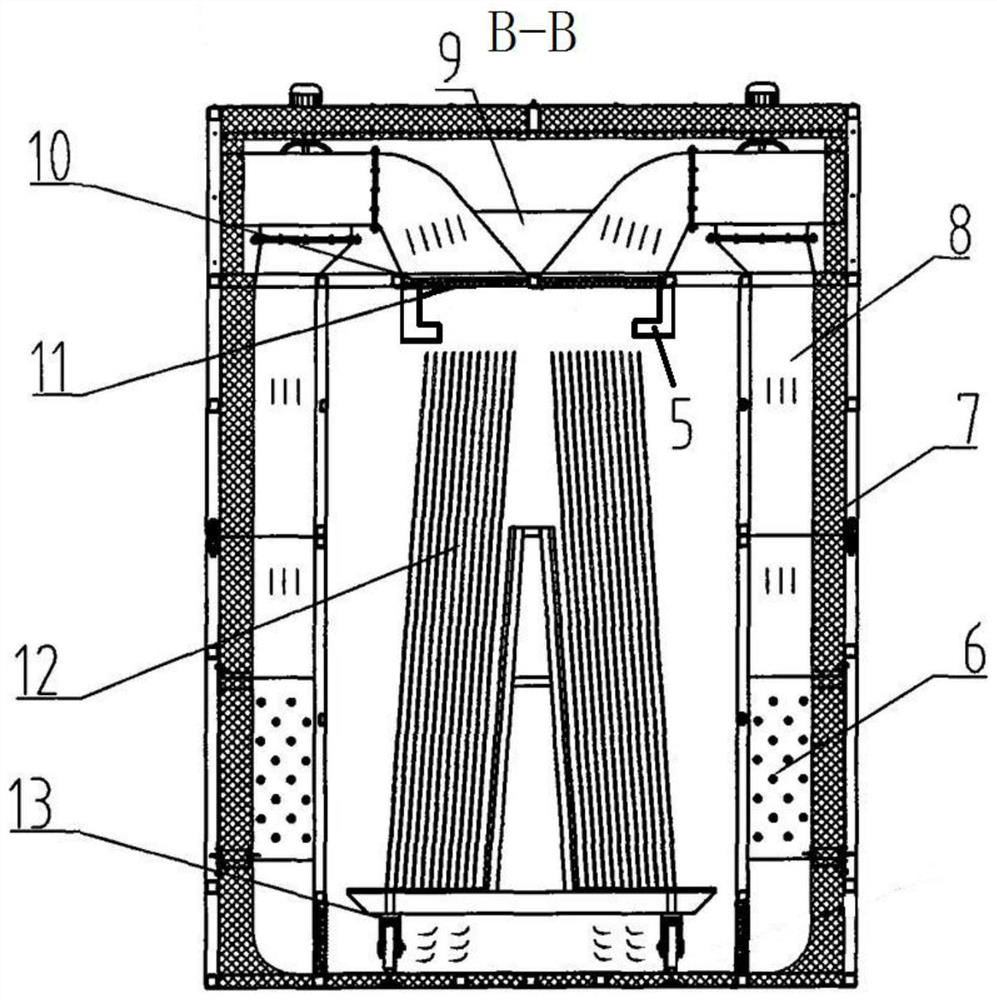

[0029] use as Figure 1-Figure 9 The structure of the tempered glass homogenization furnace according to one embodiment of the present invention will be described below.

[0030] Such as Figure 1 to Figure 7As shown, a tempered glass homogeneous furnace according to the present invention includes a furnace body 2, one end of the furnace body 2 is a furnace door 1, and the other end of the furnace body 2 is provided with a cooling fan 4, and the length direction of the furnace body 2 is divided into Five sections, each section is equipped with a heating control system and a heat balance system, an insulation layer 7 is provided around the furnace body 2, and a circulation fan 3 and a heat circulation air duct 8 are provided in the insulation layer 7 on both sides and the top of the furnace body 2; The bottom of the heat circulation air duct 8 is provided with a heater 6, and the top is provided with a circulation fan 3. The inlet and outlet of the heat circulation air duct 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com