A kind of preparation method of polyurethane-epoxy resin block copolymerization waterborne resin

A technology of epoxy resin and block copolymerization, which is applied in coatings, electrophoretic coatings, etc., can solve the problems of incomplete ring opening, affecting the storage stability of emulsions, and difficult control of the reaction process, and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 (comparative example)

[0038] Taking formula parameters Rt=1.10, H%=30w% as an example, the preparation method of polyurethane-epoxy resin block copolymerized waterborne resin is as follows:

[0039](1) Put 25.39 g of polycaprolactone diol (molecular weight Mn=2000) and 5.64 g of isophorone diisocyanate (IPDI) into the reaction bottle, the reaction temperature is 80 ℃, and react for 2 hours to prepare Obtain polyurethane prepolymer 31.03g;

[0040] The ratio of the oligomer dibasic alcohol and diisocyanate makes the ratio of the amount of substance of the isocyanate group in the diisocyanate to the ratio of the amount of substance of [OH] in the oligomer dibasic alcohol be 2:1;

[0041] (2) Add 10.00 g of epoxy E-44, 3.30 g of piperazine and 40.21 g of N,N-dimethylformamide to the polyurethane prepolymer obtained in step (1), stir evenly, heat up to 55°C, and react for 5 h ; Reaction until the epoxy value is 0, the mixture is obtained;

[0042] (3) Add ...

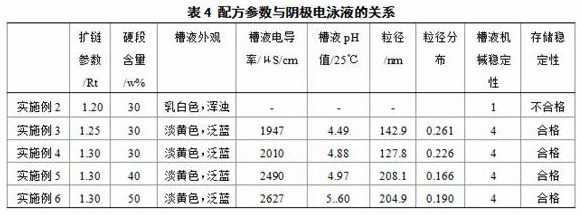

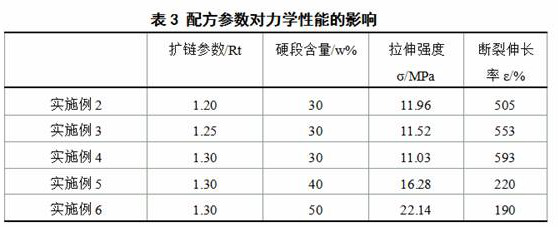

Embodiment 2

[0045] Taking formula parameters Rt=1.20, H%=30w% as an example, the preparation method of polyurethane-epoxy resin block copolymerized waterborne resin is as follows:

[0046] (1) Put 30.05 g of polycaprolactone diol (molecular weight Mn=2000) and 6.69 g of isophorone diisocyanate (IPDI) into the reaction bottle, the reaction temperature is 80 ℃, and react for 2 hours to prepare Obtain polyurethane prepolymer 36.74g;

[0047] The ratio of the oligomer dibasic alcohol and diisocyanate makes the ratio of the amount of substance of the isocyanate group in the diisocyanate to the ratio of the amount of substance of [OH] in the oligomer dibasic alcohol be 2:1;

[0048] (2) Add 11.59 g of epoxy E-44, 4.16 g of piperazine and 41.98 g of N,N-dimethylformamide to the polyurethane prepolymer obtained in step (1), stir evenly, heat up to 55°C, and react for 5 h ; Reaction until the epoxy value is 0, the mixture is obtained;

[0049] (3) Add deionized water of the same quality as the a...

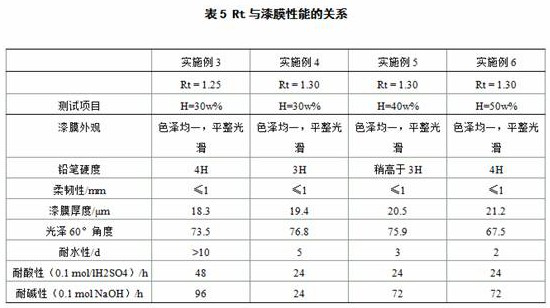

Embodiment 3

[0052] Taking formula parameters Rt=1.25, H%=30w% as an example, the preparation method of polyurethane-epoxy resin block copolymerized waterborne resin is as follows:

[0053] (1) Put 27.90 g of polycaprolactone diol (molecular weight Mn=2000) and 6.21 g of isophorone diisocyanate (IPDI) into the reaction bottle, the reaction temperature is 80 ℃, and react for 2 hours to prepare Obtain polyurethane prepolymer 34.11g;

[0054] The ratio of the oligomer dibasic alcohol and diisocyanate makes the ratio of the amount of substance of the isocyanate group in the diisocyanate to the ratio of the amount of substance of [OH] in the oligomer dibasic alcohol be 2:1;

[0055] (2) Add 10.63 g of epoxy E-44, 3.99 g of piperazine and 38.98 g of N,N-dimethylformamide to the polyurethane prepolymer obtained in step (1), stir evenly, heat up to 55°C, and react for 5 h ; Reaction until the epoxy value is 0, the mixture is obtained;

[0056] (3) Add deionized water of the same quality as the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com