Hand-held multi-angle automatic travel quick-drying marking vehicle

A multi-angle, hand-held technology, used in roads, road repair, roads, etc., can solve problems such as limited width adjustment, complex structure, and poor comfort, avoiding paint precipitation, simplifying operating procedures, and stirring. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

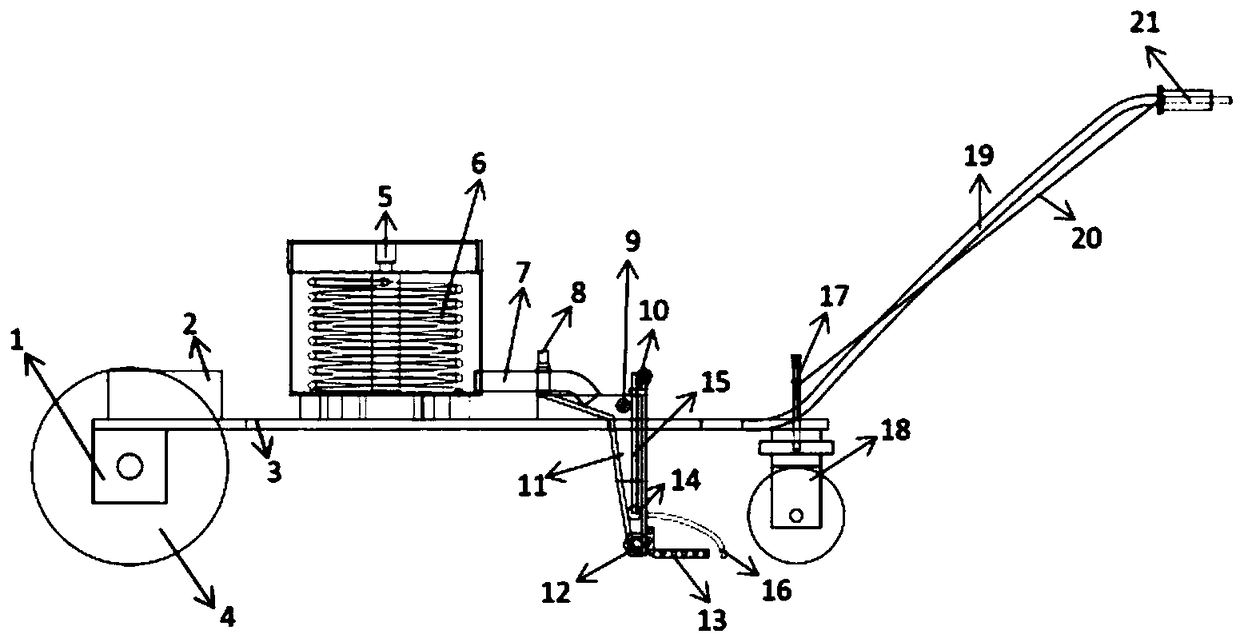

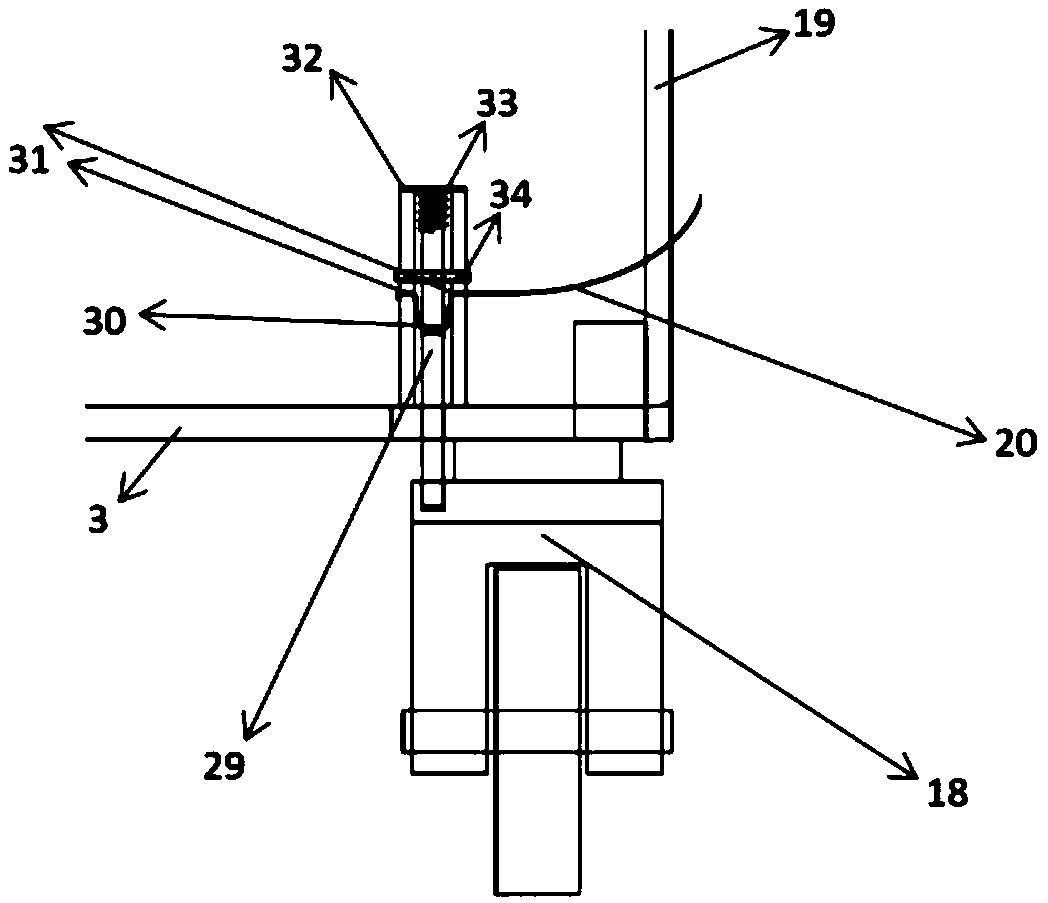

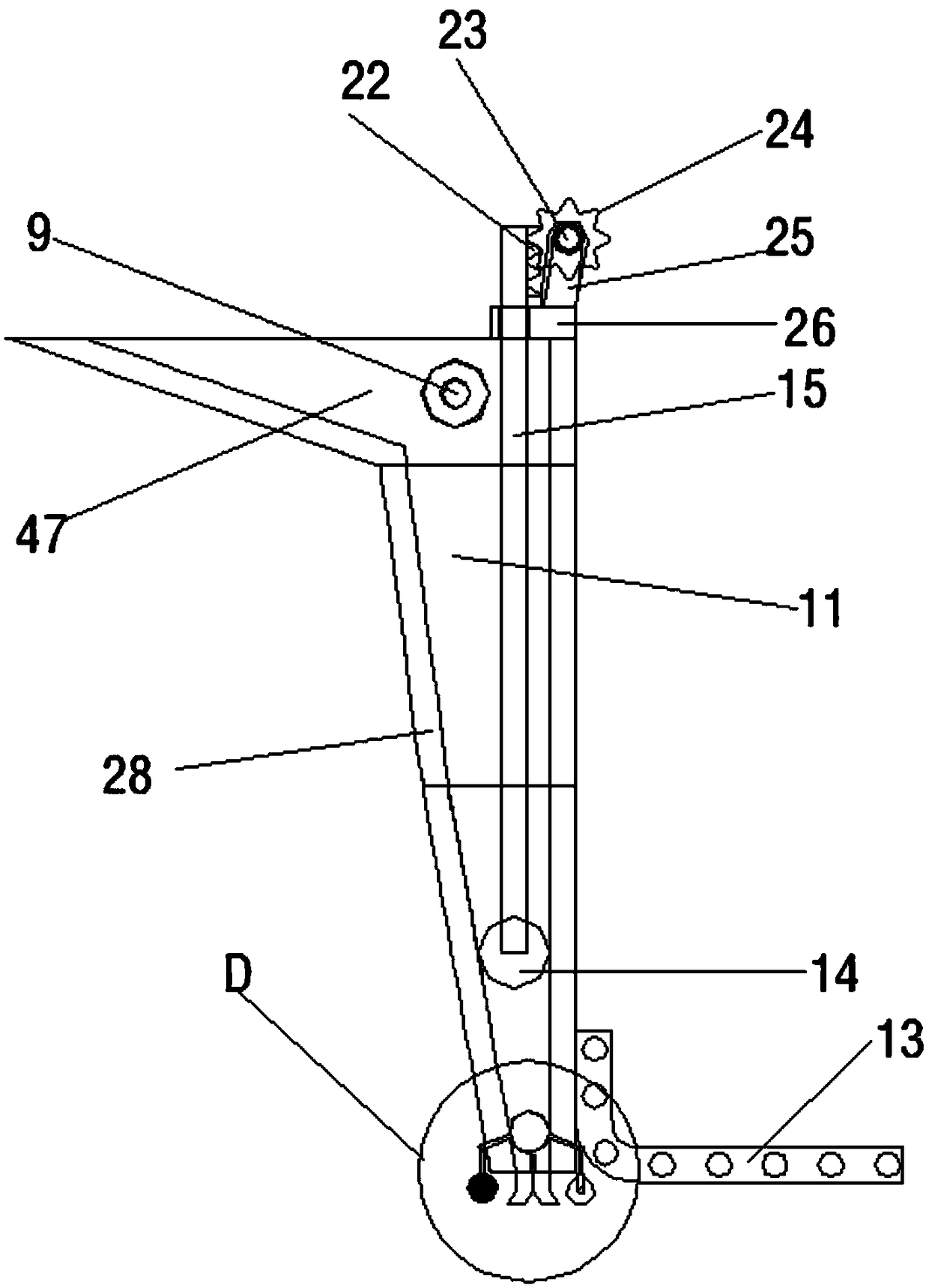

[0041] Refer to attached Figure 1-9 The walk-behind multi-angle automatic traveling fast-drying marking car shown is a hand-held multi-angle automatic traveling fast-drying marking car. The marking car includes a marking car body, a paint mixing mechanism, a material discharging and marking mechanism and A quick-drying mechanism, the paint stirring mechanism is arranged on the marking car body, the discharge and marking mechanism is arranged at the discharge end of the paint stirring mechanism, and the quick-drying mechanism is arranged on the discharging and marking The rear end of the wire mechanism, wherein;

[0042] The marking car body includes a base plate 3, two front moving wheels 4, two rear steering whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com