A method for erecting a cable-stayed suspension cable cooperative system bridge

A cable-stayed and suspended cable technology, applied in cable-stayed bridges, bridge construction, bridges, etc., can solve the problems of long side span cantilever, too large cable force difference of the main tower, prolonged construction period of beam erection, etc., saving construction period, Reduce the difficulty and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

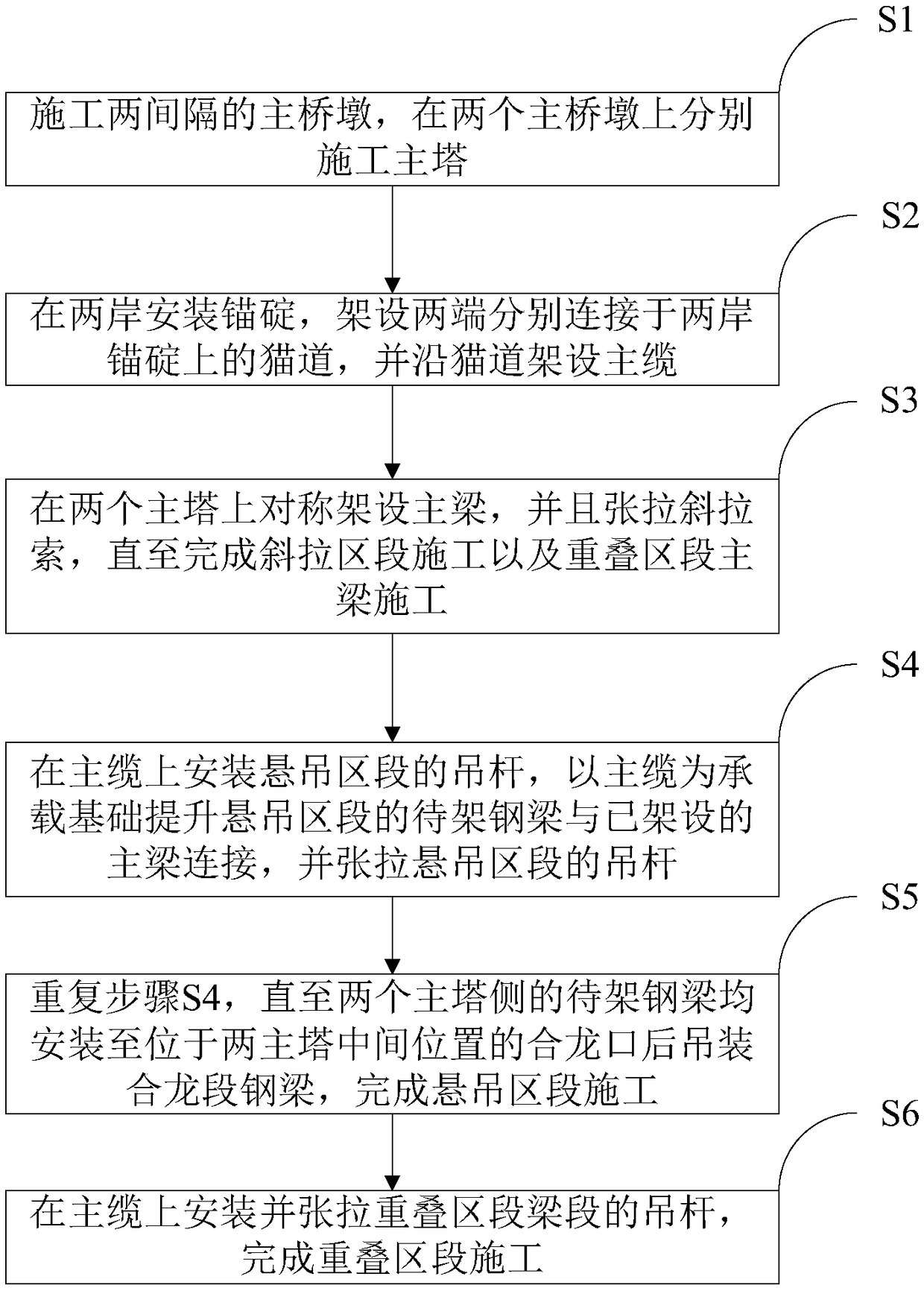

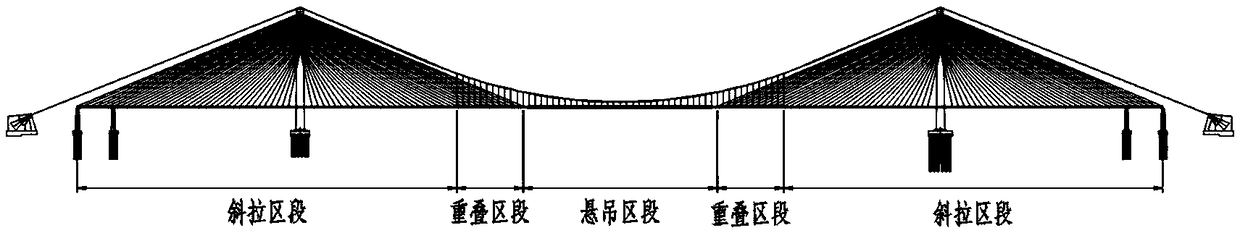

[0037] see figure 1 As shown, the embodiment of the present invention provides a bridge erection method of a cable-stayed and suspended cable cooperative system, comprising the following steps:

[0038] Step S1, see image 3 As shown, two main piers at intervals are constructed, and the main tower 7 is constructed respectively on the two main piers. Meanwhile, the side pier 8 between the main pier and the two sides can also be constructed, so as to improve the construction efficiency.

[0039] Step S2, see image 3 , Figure 4 As shown, the anchorage 9 is installed on both banks, and the catwalk 13 with two ends connected to the anchorage 9 on both sides of the bank is erected, and the main cable 1 is erected along the catwalk 13 .

[0040] Step S3, see Figure 4 , Figure 5 As shown, the main girder 4 is erected symmetrically on the two main towers 7, and the stay cables 2 are stretched until the construction of the cable-stayed section and the construction of the main b...

Embodiment 2

[0045] On the basis of Embodiment 1, preferably, the main cable 1 and the main beam 4 of the cable-stayed section are erected synchronously, which can save construction time and cost. The main beam 4 of the cable-stayed section is gradually erected from the main tower 7 to both sides, The main girder 4 can be put on the pier as soon as possible to ensure the symmetry in the erection process of the main girder 4 and reduce the safety risk in the construction process.

Embodiment 3

[0047] On the basis of Example 1, the suspender 3 in the overlapping section is not stretched first, and after the construction of the overlapping section, the suspender 3 in the overlapping section is stretched, and the cable force of the whole bridge is adjusted to make the structure linear , internal forces, etc. reach the designed bridge state. Adopting this construction method ensures the symmetry in the erection process of the main beam 4, reduces the bending moment of the main tower 7, improves the stress of the main tower in the erection process, and ensures construction safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com