Automatic translational electromagnetic shielding door

An electromagnetic shielded door, automatic technology, applied in the field of shielded doors, can solve the problems of inconsistent contact pressure of spring sheets, poor consistency, uniform wall thickness and accuracy of pneumatic tires, and it is difficult to ensure dimensional consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

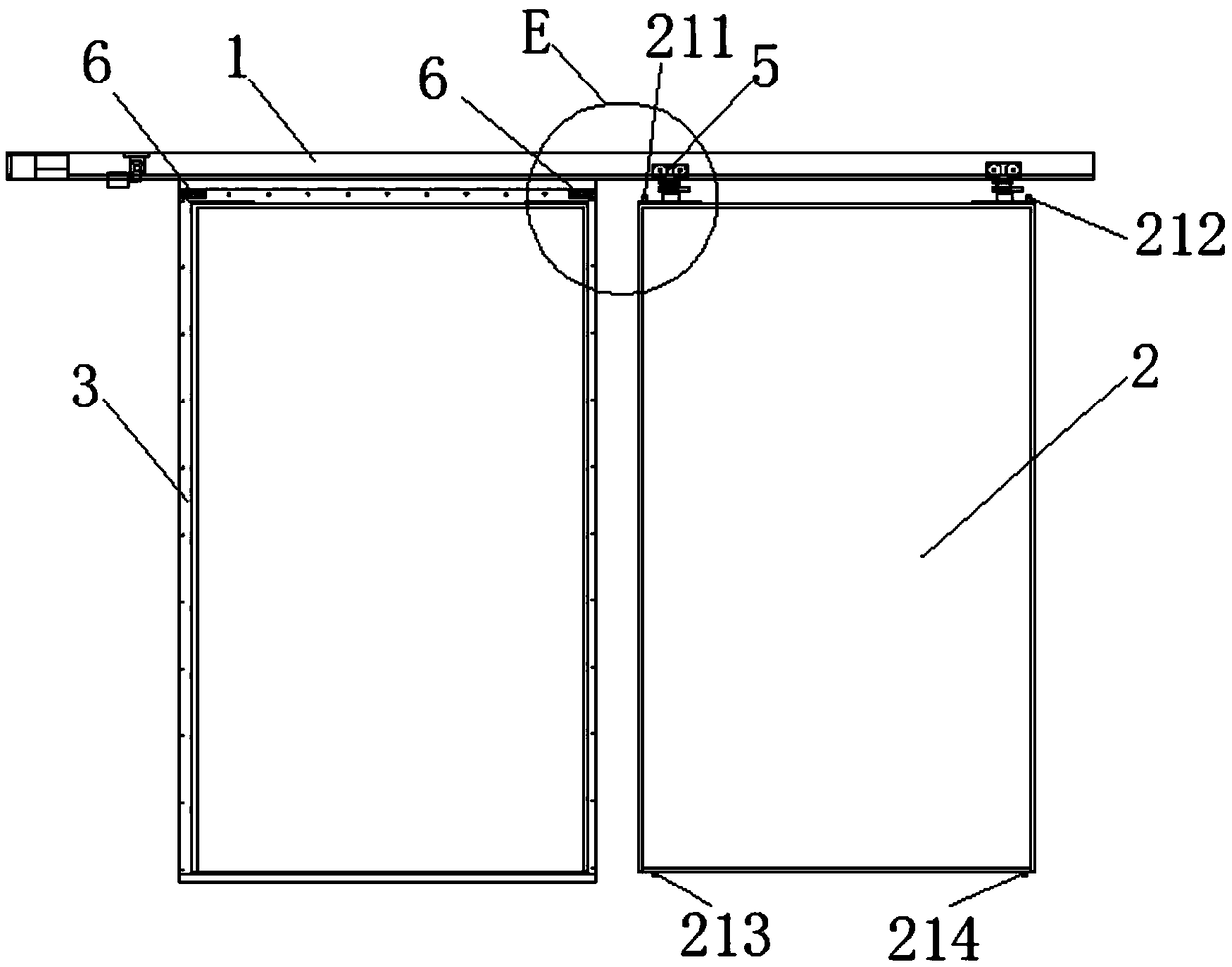

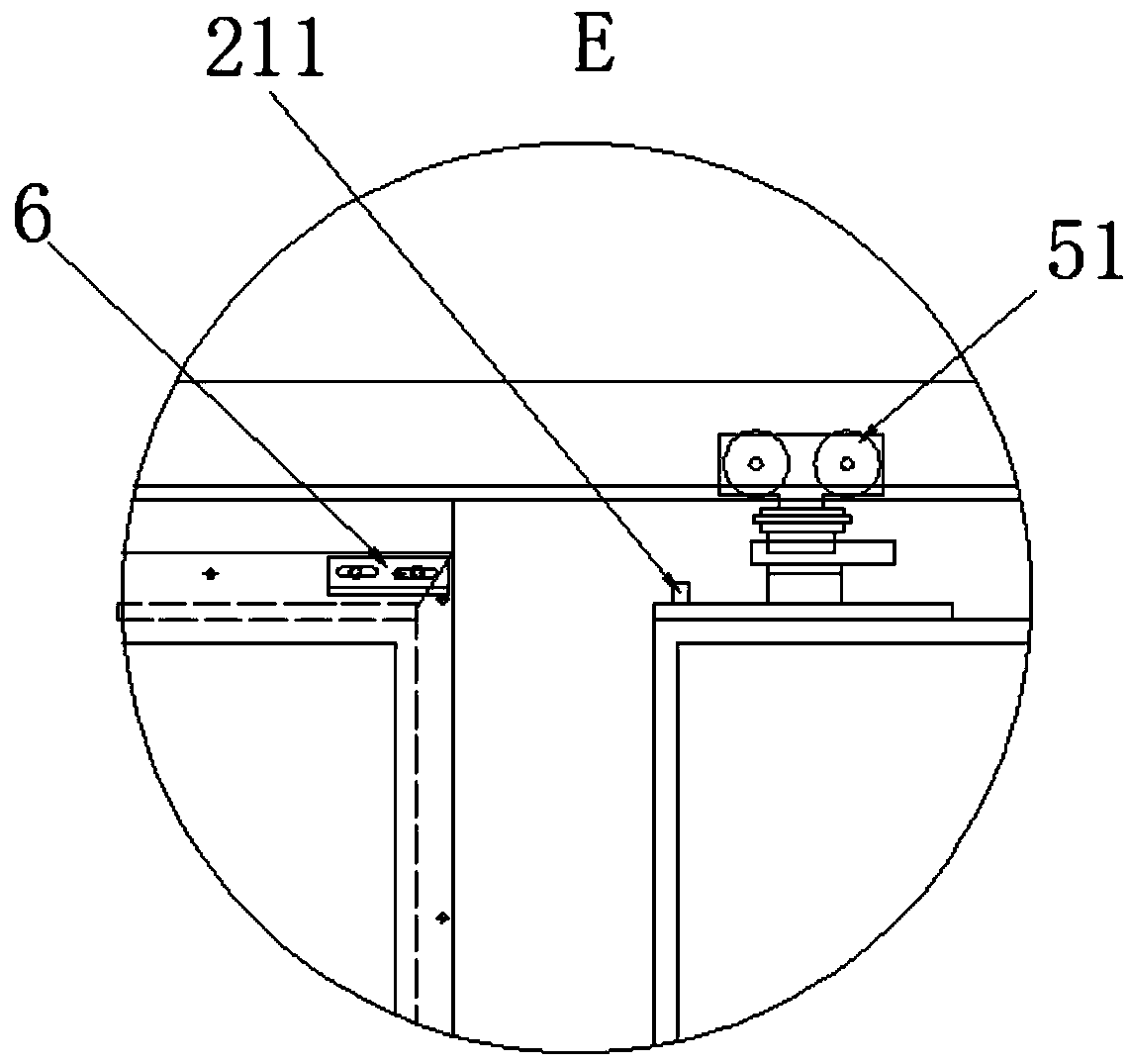

[0030] Such as Figure 1 to Figure 6 As shown, an automatic translational electromagnetic shielding door includes a door frame 3, a door leaf 2, a hanging assembly 5 and a motor unit.

[0031] The motor unit includes a translational slide rail 1 and a motor assembly for driving the suspension assembly 5 to slide along the translational slide rail 1. The translational slide rail 1 is generally installed on the wall above the door frame 3, and its direction is parallel to the direction of the door frame. The translational slide rail plays a role in guiding the movement of the door leaf. The door leaf 2 moves along the translational slide rail 1 to the door frame 3 during the closing process. Swipe in the direction. The motor assembly preferably drives the suspension assembly 5 to move through a belt. The hanging assembly 5 can be fixedly connected to the belt. The belt is laid along the entire translational slide rail 1. The hanging assembly 5 is fixedly connected to the lower si...

Embodiment 2

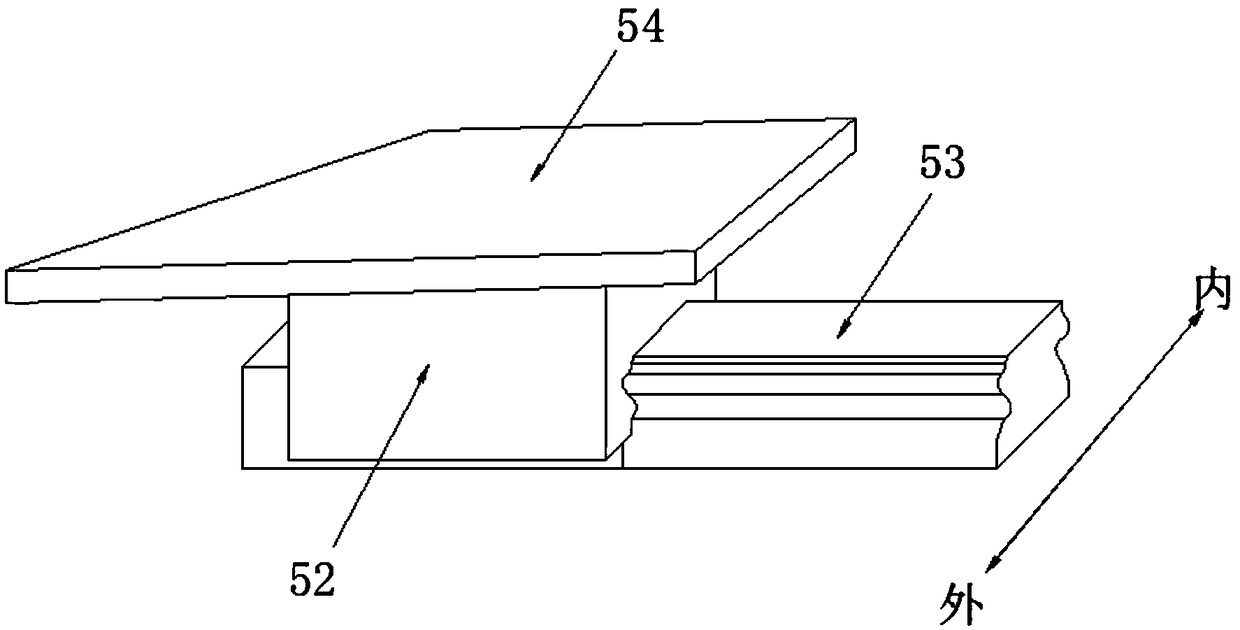

[0042] On the basis of embodiment 1, this embodiment 2 further improves the assembly structure of the inclined chute and the guide post. A connecting plate 6 is fixedly connected to the top of the door frame 3. Figure 5 The specific structure of the connecting plate 6 is shown. The connecting plate 6 is provided with the inclined sliding groove, which is called the first inclined sliding groove 41, and the bottom of the door frame 3 is directly opened with the inclined sliding groove, which is called the second inclined sliding groove 42. The first inclined chute is opened on the connecting plate 6 instead of directly on the top of the door frame, which increases the flexibility of the first inclined chute and the guide post on the top of the door leaf. The inclination angle of the first oblique sliding groove 41 and the second oblique sliding groove 42 is the same as that of the slider guide rail, which is also 45°.

[0043] figure 1 The setting positions of the four guide pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com