Multi-stage filter separated type air filter

An air filter, split technology, used in fuel air filter, combustion air/combustion-air treatment, machine/engine, etc., can solve the problem of single function of filtering air impurities, affecting the filtering effect and assembly of the filter efficiency and other issues, to achieve the effect of improving the overall quality, compact structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with reference to the drawings and embodiments.

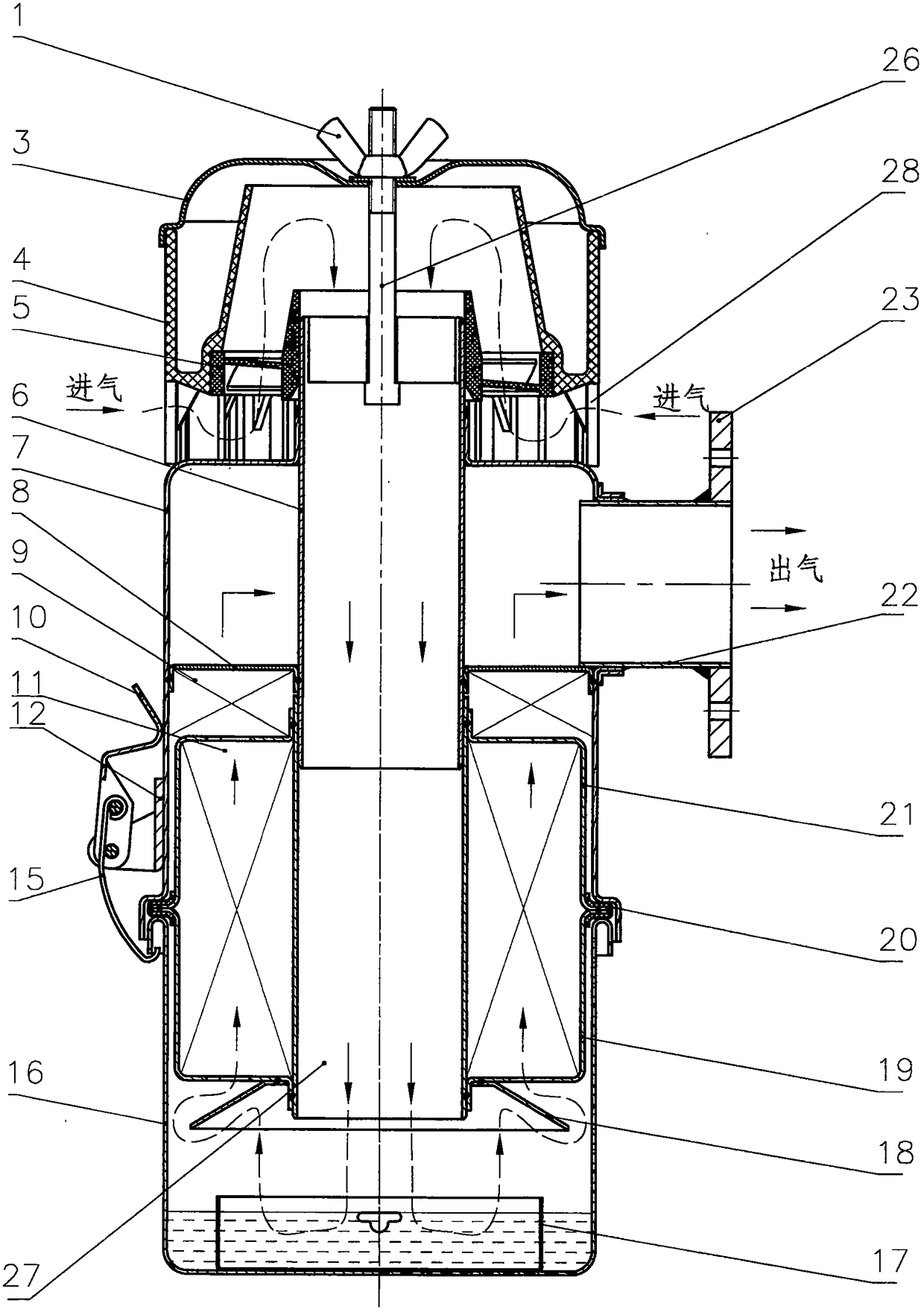

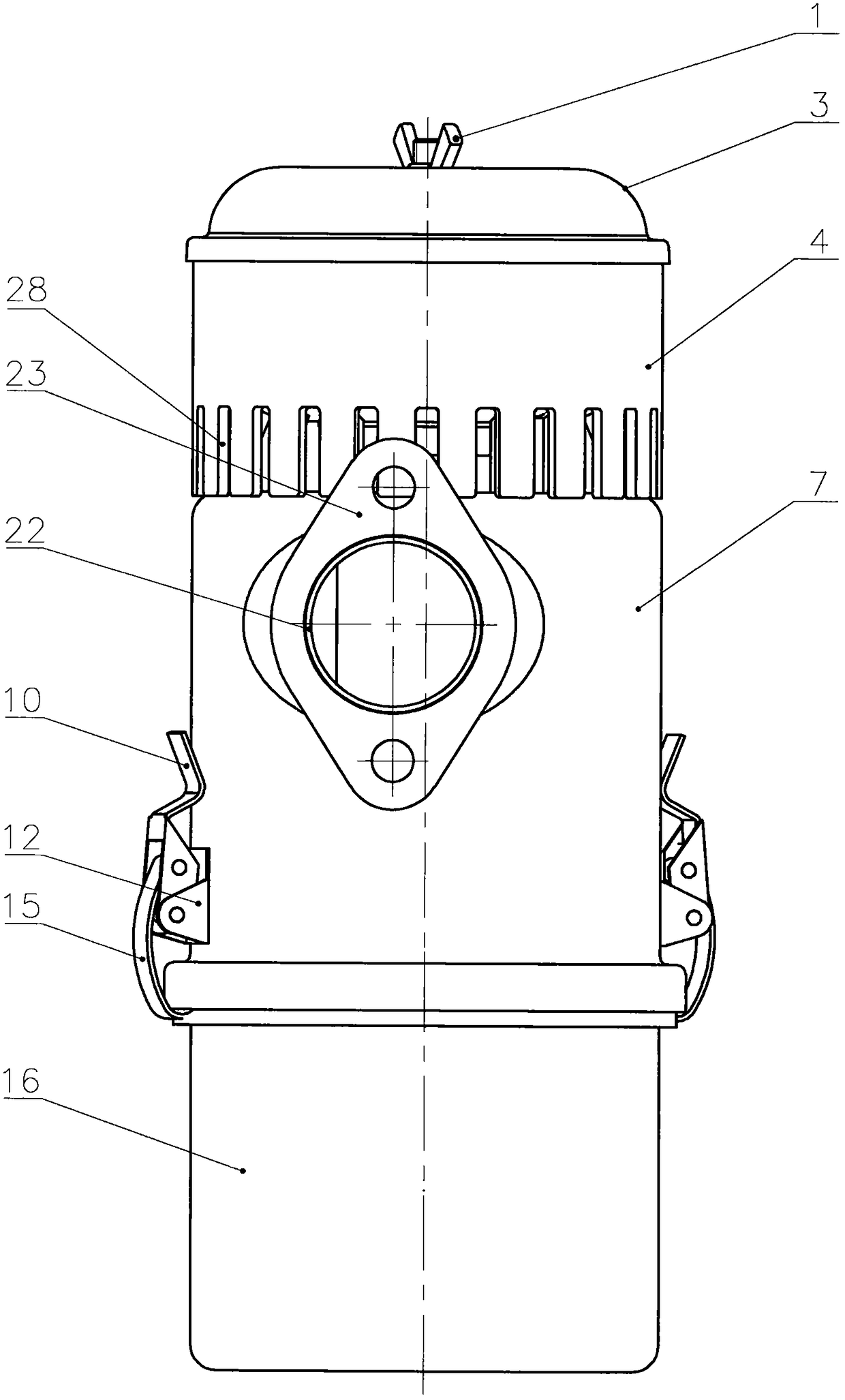

[0010] refer to figure 1 , figure 2 It can be seen that the multi-stage filter split air filter of the present invention includes an outer shell and a fine filter assembly, and the outer shell is sequentially composed of an upper cover 3, a middle shell 7, and a lower shell 16. In the middle shell 7 is equipped with an air intake pipe 6, the upper end of the air intake pipe 6 is equipped with a primary coarse filter assembly 5, between the upper cover 3 and the middle housing 7, and at the side of the primary coarse filter assembly 5 Dust cup 4; the fine filter assembly is installed in the middle casing 7 and the lower casing 16 and is fitted with the lower end of the air intake pipe 6, and the middle casing 7 is externally connected to the air outlet pipe 22. Between the dust cup 4 and the middle housing 7 , and at the side of the primary coarse filter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com