Composite water-cooled wall, water-cooled flue and water-cooled furnace lid

A composite, water-cooled wall technology, applied in furnaces, furnace cooling, furnace components, etc., can solve the problems of high thermal conductivity, low thermal conductivity, large heat loss, etc. The effect of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

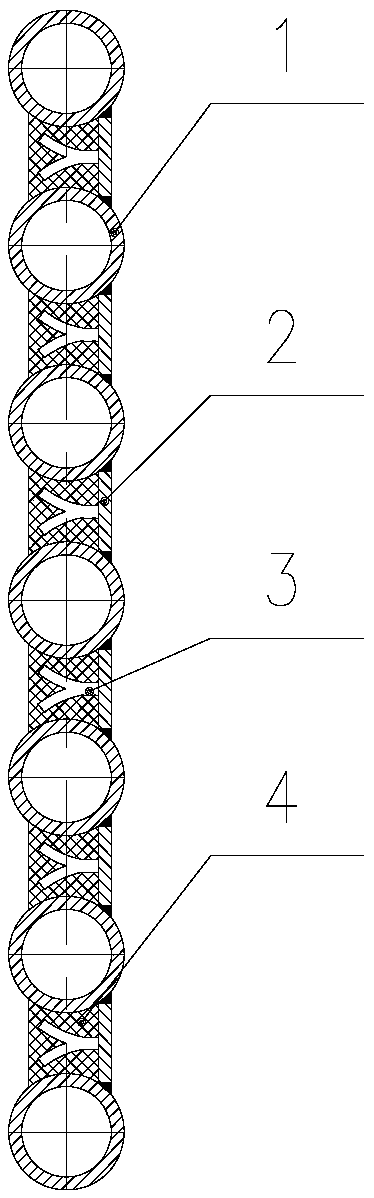

[0032] refer to figure 1 , 4 , the composite water-cooled wall of this embodiment is mainly composed of a water-cooled tube 1, a sealing plate 2, a slag-hanging nail 3, and a refractory material 4. The sealing plate 2 is arranged on the back side of the water-cooled tube 1 and is used for single-sided sealing and connection. The water-cooled pipe 1 of the circuitous structure, the circuitous structure adopts a serpentine spaced arrangement structure, of course, in different embodiments, a circuitous spaced structure can also be used, and the sealing plate adopts a block type, that is, the sealing plate includes multiple, and are respectively located in the detour interval area a of the water-cooling pipe, the sealing plate 2 is directly welded to the water-cooling pipe 1, and the sealing plate 2 is provided with several The slag-hanging nails 3 are arranged in a criss-cross arrangement on the sealing plate 2, and the two are connected by welding. The refractory material 4 is ...

Embodiment 2

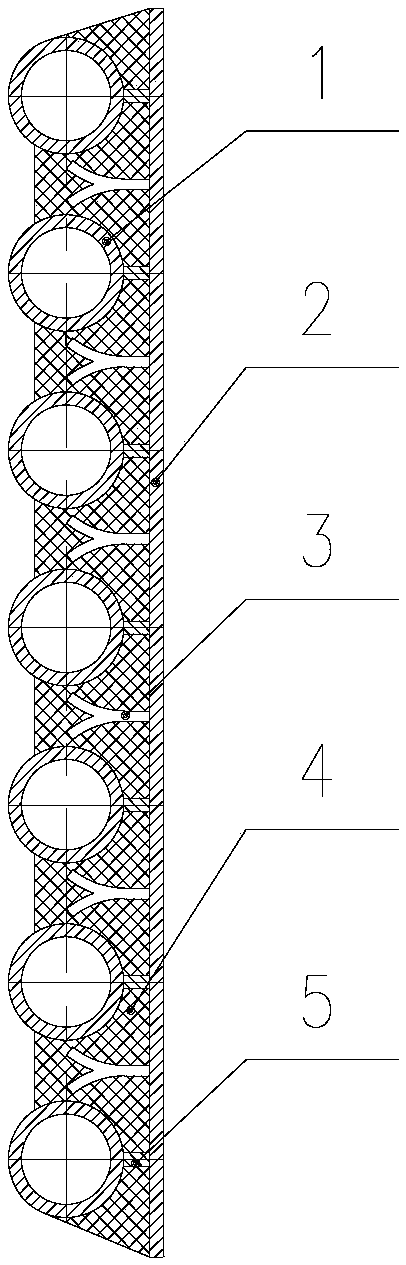

[0034] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that the sealing plate adopts a monolithic structure, and the sealing plate and the water-cooling tube are welded through stiffener plates. In this way, the amount of refractory material used in the detour interval area a of the water-cooled pipe 1 can be increased, and the high-temperature resistance performance of the composite water-cooled wall can be further improved.

Embodiment 3

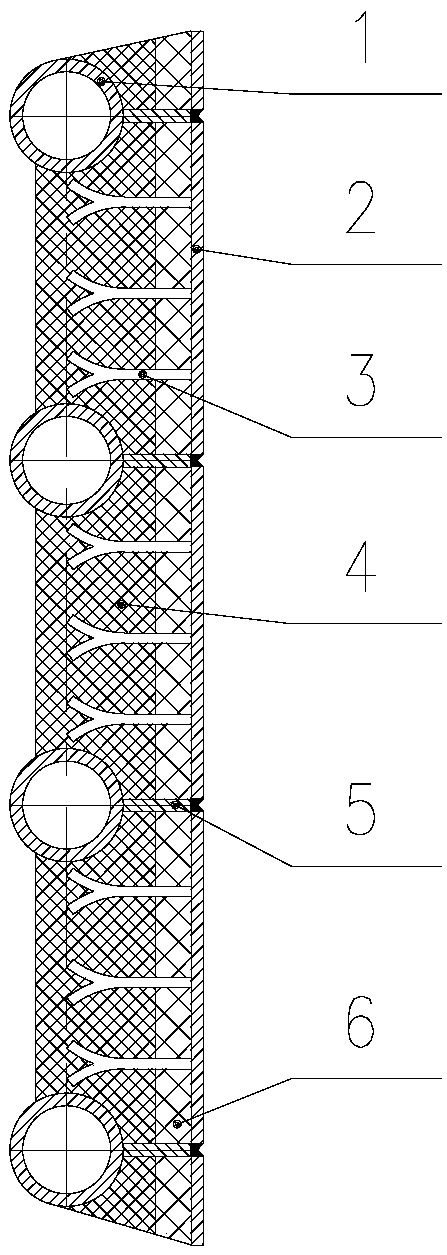

[0036] Such as image 3 As shown, the difference between this embodiment and the second embodiment is that a heat insulating layer 6 is added between the sealing plate 2 and the refractory material 4 . The high temperature resistance performance of the composite water wall can be further improved.

[0037] Additionally, if Figure 5 , 6 , 7, the present invention also provides a water-cooled flue, which is enclosed by the above-mentioned composite water-cooled wall, and its cross-sectional shape can be rectangular, circular or runway-shaped; or variable cross-section structures.

[0038] Additionally, if Figure 8 , 9 As shown, the present invention also provides a water-cooled furnace cover made of the above-mentioned composite water-cooled wall. It can be used for the furnace cover of electric arc furnace and LF furnace.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap