On-line detection system for train pantograph

A detection system and pantograph technology, applied in the detection field, can solve problems such as low detection accuracy, unstable operation, complex system, etc., and achieve the effects of meeting detection requirements, stable image acquisition, and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

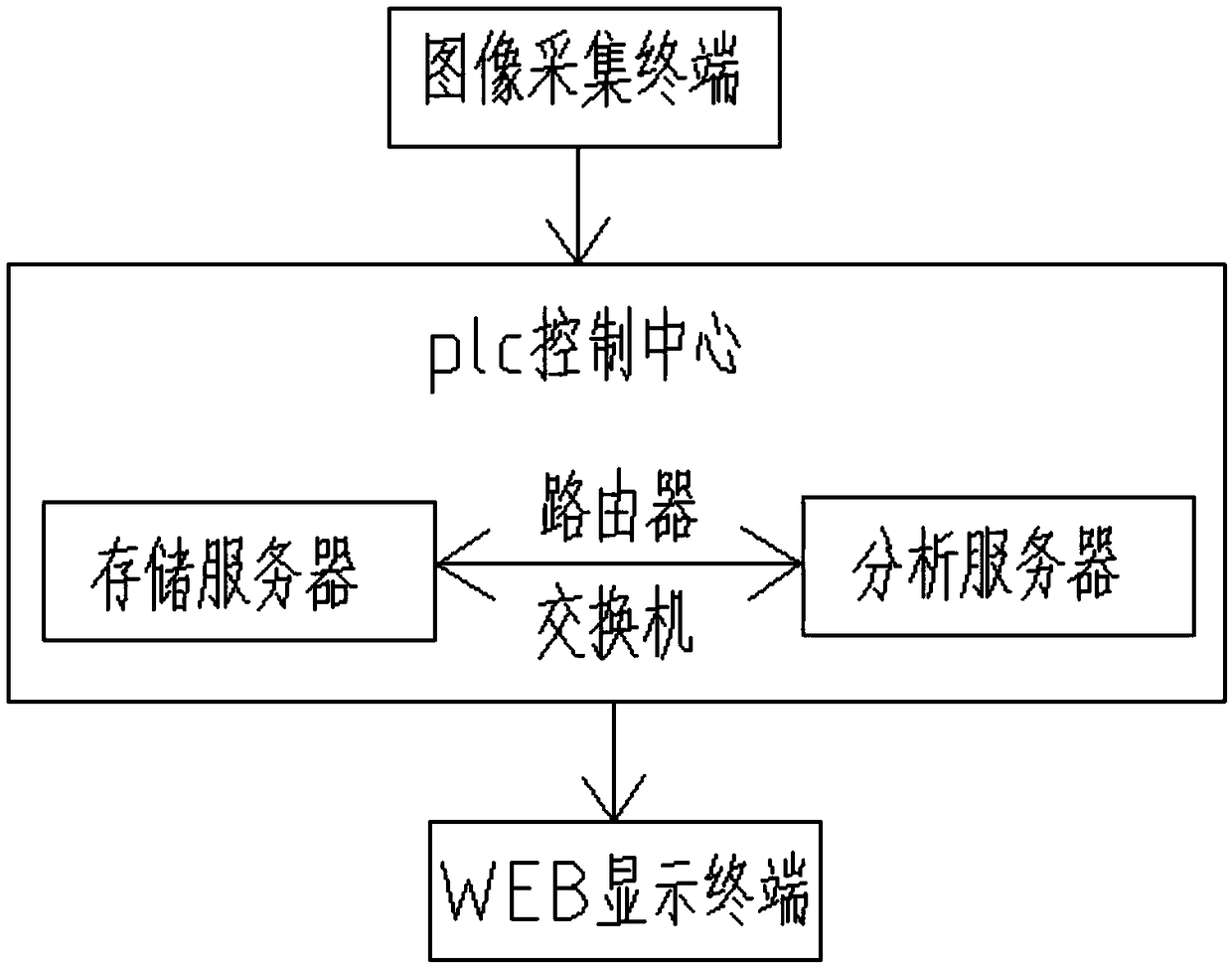

[0025] A train pantograph online detection system, such as figure 1 As shown, it includes image acquisition terminal, storage server, image analysis server, PLC control system and WEB display terminal.

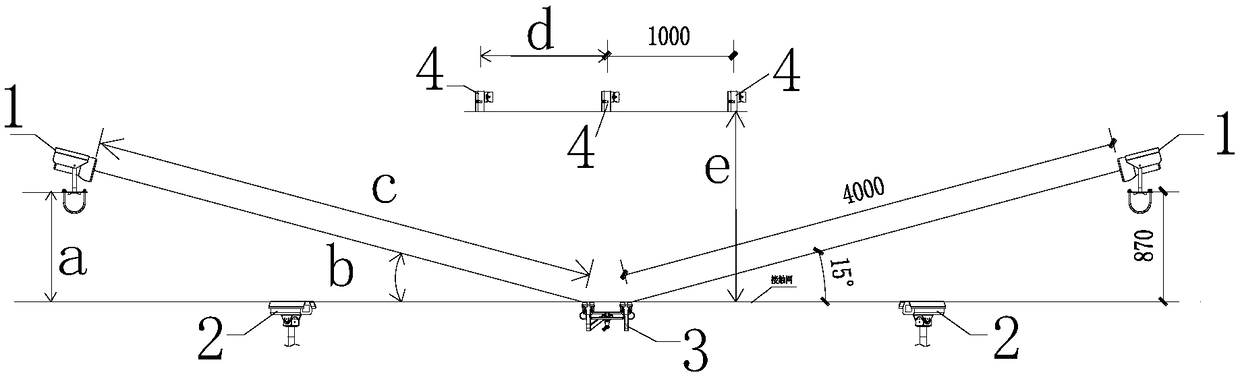

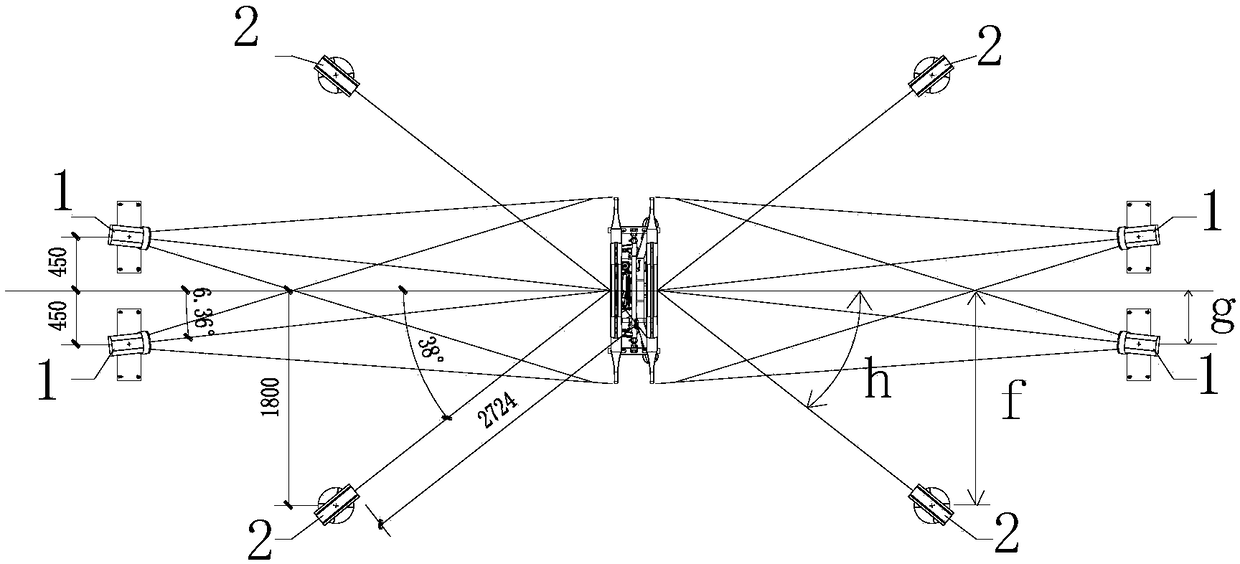

[0026] The image acquisition terminal includes two industrial cameras and a positioning sensor respectively arranged on the front and back sides of the detected pantograph, and is installed at the position below the catenary at the same height as the pantograph, and is installed on the side of the pantograph through the positioning sensor; when the train When passing, the positioning sensor signal is input to the PLC cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap