Protective element and circuit protective device thereof

A protection component and circuit protection technology, which is applied in the direction of emergency protection devices, components of protection switches, circuits, etc., can solve the problems that the cost of the protection component 100 is not easy to further reduce, the height of the outer cover 170 is not easy to be further reduced, and it does not conform to thinning, etc. , to achieve the effect of reducing the loss of defective product scrapping, overcoming inaccurate fusing time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the above and other technical contents, features and advantages of the present invention more comprehensible, the following specifically cites relevant embodiments, together with the accompanying drawings, for a detailed description as follows.

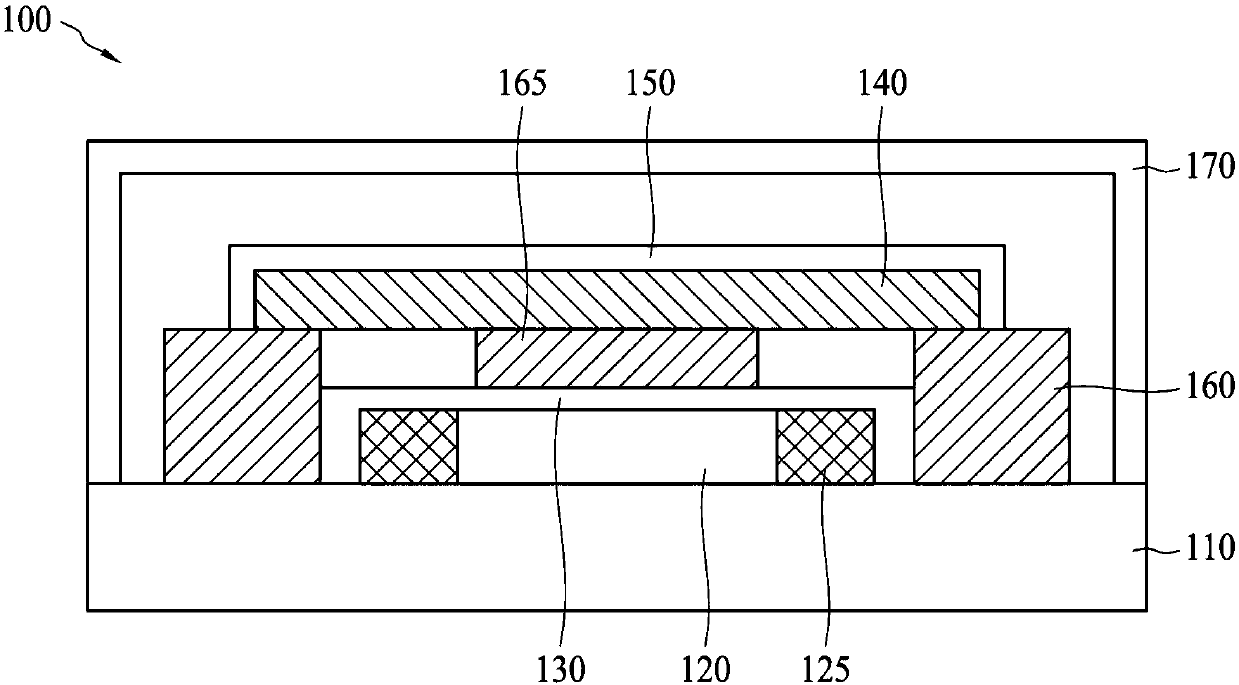

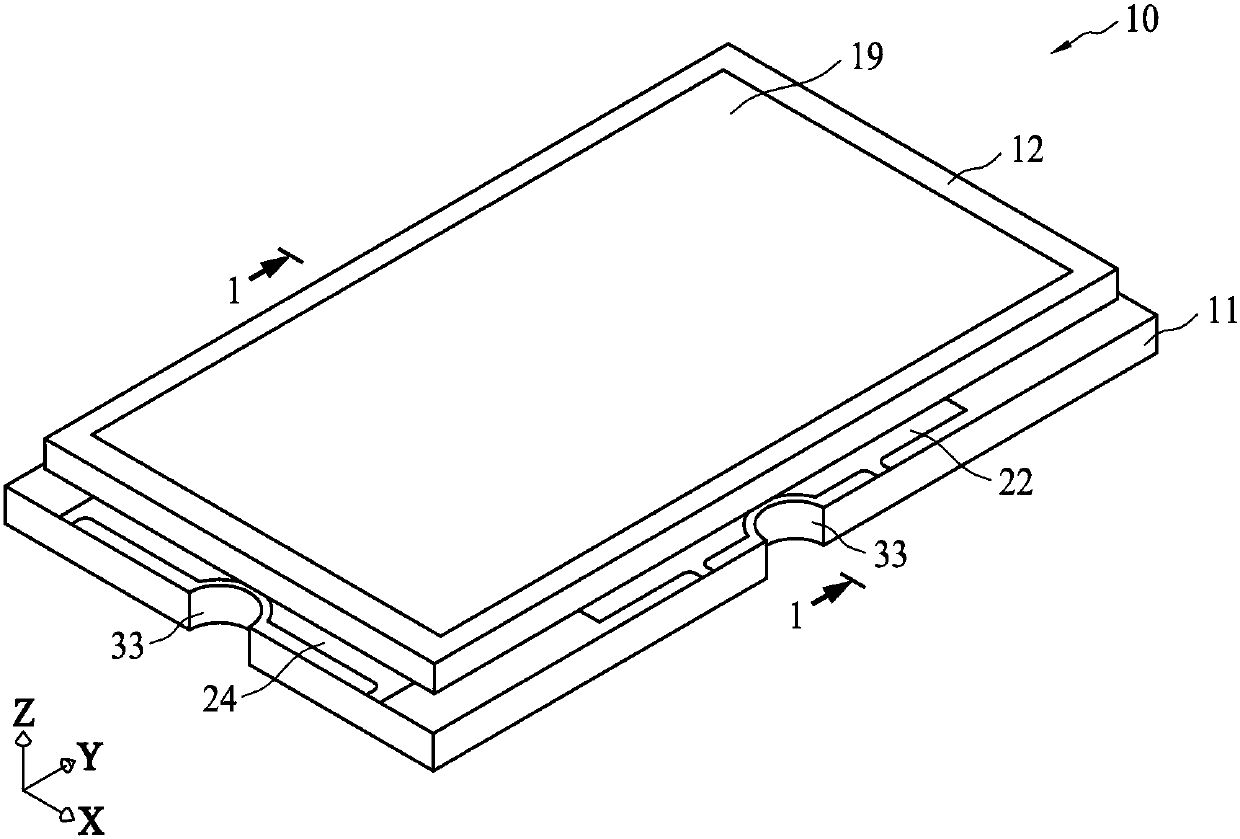

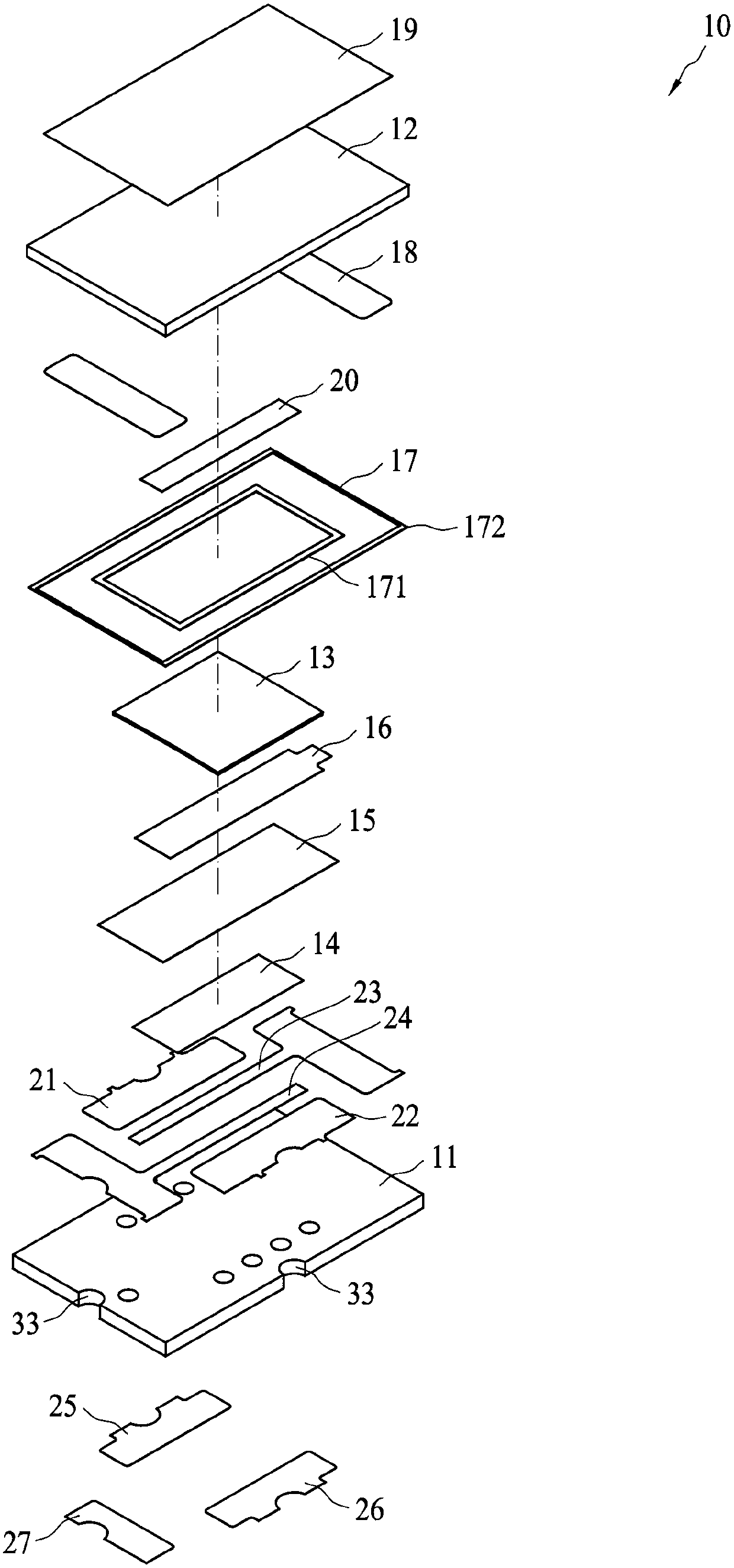

[0071] figure 2 It is a three-dimensional structure diagram of the protection element 10 according to the first embodiment of the present invention, Figure 3A is an exploded perspective view of the protective element 10, Figure 4 then figure 2 A cross-sectional view of the middle protective element 10 along the section line 1-1. The protection element 10 includes a first planar substrate 11, a second planar substrate 12, a fuse 13, a heating element 14, an insulating layer 15, an electrode layer 16, an insulating frame 17, silver glue 18, a protective layer 19, an adsorption member 20, a first Electrode 21 , second electrode 22 , third electrode 23 , fourth electrode 24 , pad 25 , pad 26 and pad 27 . Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com