Method for reducing dielectric loss factor of dielectric oil

A technology of dielectric loss factor and loss factor, applied in separation methods, chemical instruments and methods, petroleum industry, etc., can solve the problems of high dielectric loss factor, achieve high vacuum pressure, improve interfacial tension and volume resistivity, and reduce dielectric loss Factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

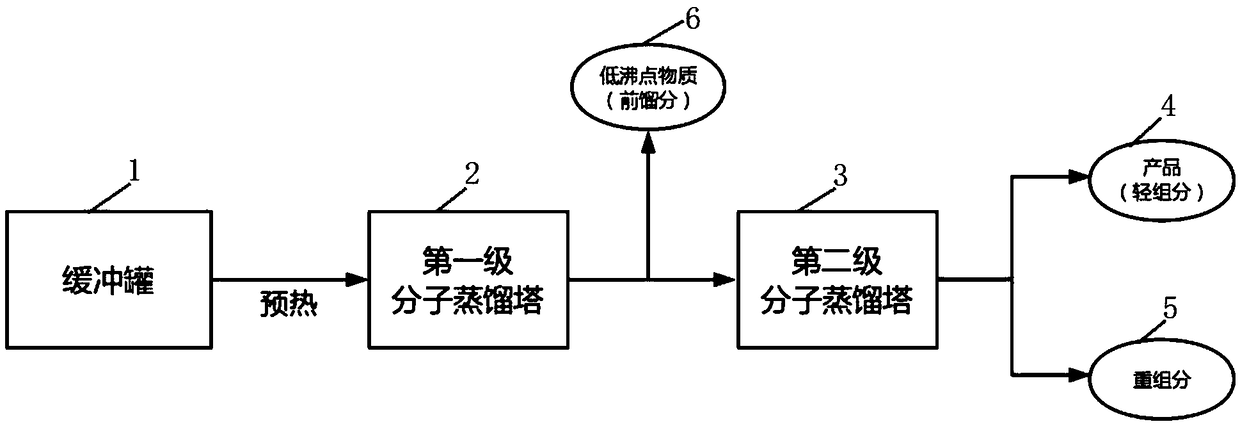

Method used

Image

Examples

Embodiment 1

[0045]The embodiment of the present invention provides the first kind of specific implementation mode, take No. 1 power supply bureau insulating oil (old oil) and carry out the first stage molecular distillation, the temperature of the first stage molecular distillation is 50 ℃, the vacuum of the first stage molecular distillation The pressure is 10Pa, the feed rate of the first stage molecular distillation is 15Kg / h, and the first stage molecular distillation insulating oil can be obtained. The first stage molecular distillation can remove the substances with low boiling point in the insulating oil (old oil) and provide First-stage molecular distillation preheating; the first-stage molecular distillation insulating oil is subjected to second-stage molecular distillation, the temperature of the second-stage molecular distillation is 175°C, the vacuum pressure of the second-stage molecular distillation is 2Pa, and the feedstock of the second-stage molecular distillation The spee...

Embodiment 2

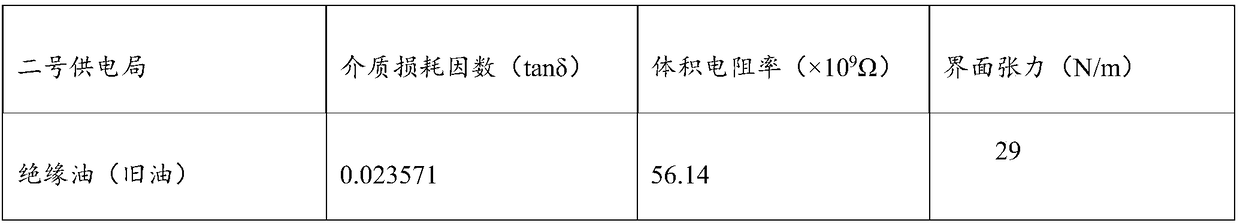

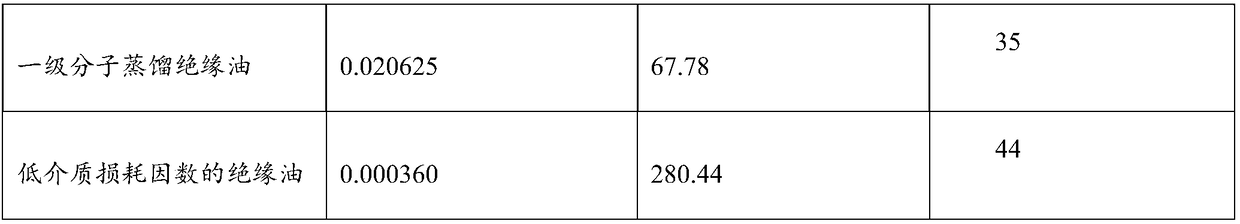

[0049] The embodiment of the present invention provides a second specific implementation mode. The insulating oil (old oil) of the No. 2 power supply bureau is used for the first-stage molecular distillation. The temperature of the first-stage molecular distillation is 100°C. The pressure is 25Pa, the feed rate of the first stage molecular distillation is 15Kg / h, and the first stage molecular distillation insulating oil can be obtained. The first stage molecular distillation can remove the substances with low boiling points in the insulating oil (old oil) and provide First-stage molecular distillation preheating; the first-stage molecular distillation insulating oil is subjected to second-stage molecular distillation, the temperature of the second-stage molecular distillation is 180°C, the vacuum pressure of the second-stage molecular distillation is 1Pa, and the feed of the second-stage molecular distillation The speed is 15Kg / h, and the insulating oil with low dielectric loss...

Embodiment 3

[0054] The embodiment of the present invention provides a third specific implementation mode. The insulating oil (old oil) of the No. 3 power supply bureau is used for the first-stage molecular distillation. The temperature of the first-stage molecular distillation is 150° C., and the vacuum Pressure is 50Pa, under the condition of the feeding speed of first-order molecular distillation 15Kg / h, obtain first-order molecular distillation insulating oil, the material with low boiling point in insulating oil (old oil) is removed, and prepare for the second-stage molecular distillation Heat; the temperature of the second-stage molecular distillation is 185°C, the vacuum pressure of the second-stage molecular distillation is 2Pa, and the feed rate of the second-stage molecular distillation is 15Kg / h, so as to obtain insulating oil with low dielectric loss factor. The distilled insulating oil is collected separately through the light component tank and the heavy component tank, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com