Double-sided milling machine

A milling machine, double-sided technology, applied in the field of milling machines, to achieve the effect of strong practicability, increasing stability and structural strength, and overcoming the overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

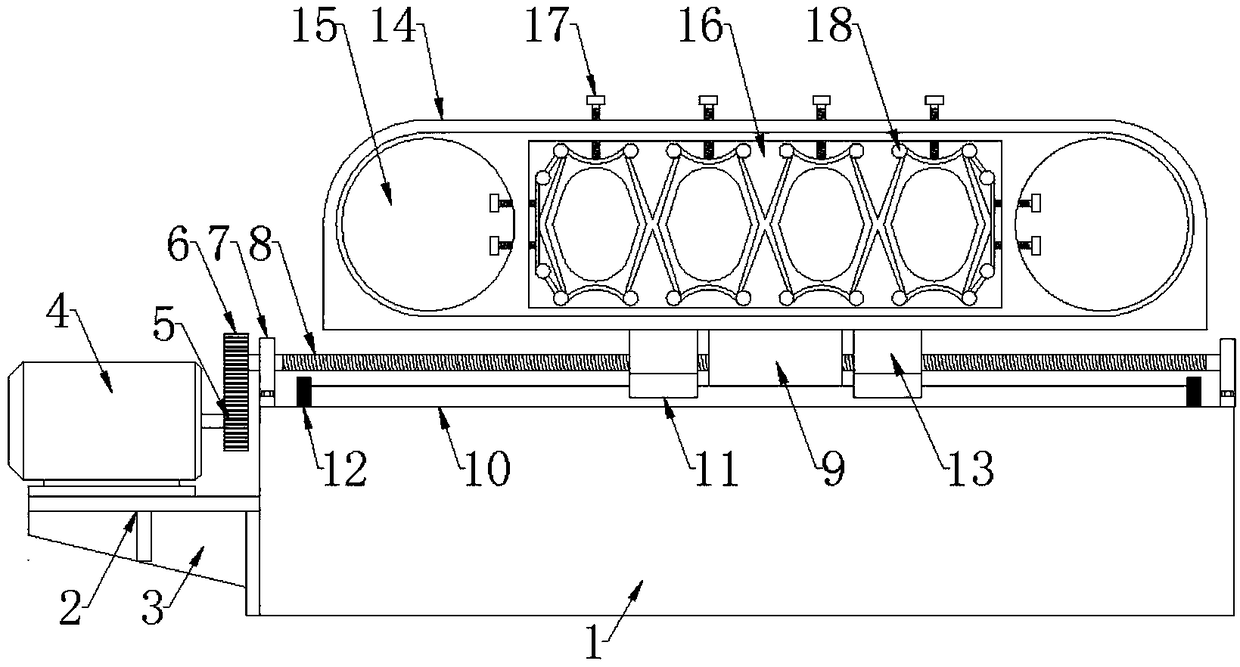

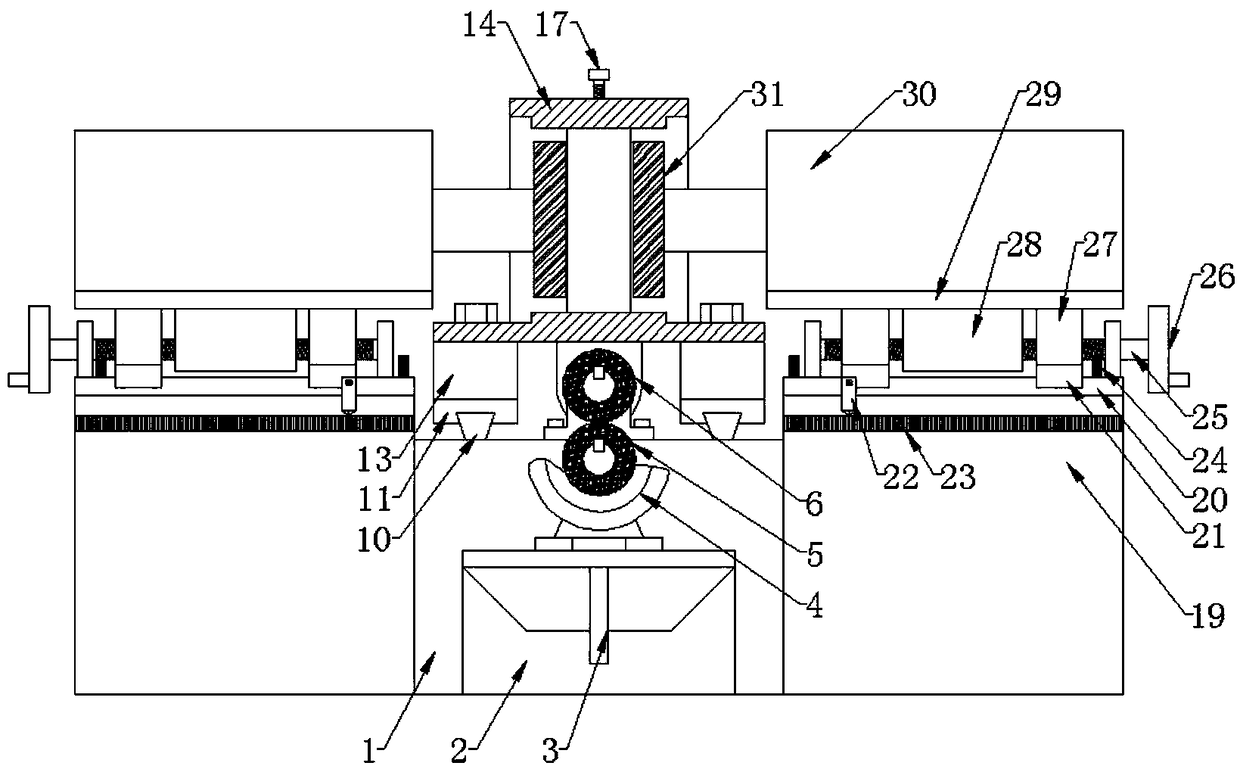

[0021] Such as Figure 1 to Figure 2 As shown, a double-sided milling machine includes a workpiece fixing device and a workpiece milling device, and the workpiece milling device is symmetrically arranged on both sides of the workpiece fixing device,

[0022] The workpiece fixing device includes a support platform-1 and a servo motor 4, the servo motor 4 is horizontally installed on the front end surface of the support platform-1 through the motor fixing plate-2, and a gear-1 is installed at the end of the rotating shaft of the servo motor 4. 5. The gear 2 6 is meshed above the gear 1 5, the gear 2 6 is mounted on the front end of the screw 1 8, and the screw 1 8 is horizontally installed on the upper end surface of the support table 1 1 through the bearing seat 1 7 , said leading screw one 8 is threadedly connected with slide block one 9, the upper end of said slide block one 9 is equipped with support frame 14, and the left and right sides of the bottom of said support frame ...

Embodiment 2

[0026] Such as Figure 1 to Figure 2 As shown, a double-sided milling machine includes a workpiece fixing device and a workpiece milling device, and the workpiece milling device is symmetrically arranged on both sides of the workpiece fixing device,

[0027] The workpiece fixing device includes a support platform-1 and a servo motor 4, the servo motor 4 is horizontally installed on the front end surface of the support platform-1 through the motor fixing plate-2, and a gear-1 is installed at the end of the rotating shaft of the servo motor 4. 5. The gear 2 6 is meshed above the gear 1 5, the gear 2 6 is mounted on the front end of the screw 1 8, and the screw 1 8 is horizontally installed on the upper end surface of the support table 1 1 through the bearing seat 1 7 , said leading screw one 8 is threadedly connected with slide block one 9, the upper end of said slide block one 9 is equipped with support frame 14, and the left and right sides of the bottom of said support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com