A ship hull and a method for assembling the hull

A hull and hull technology, applied in the field of ships, can solve the problems of damage to the driver's life safety, reduce the convenience of maintenance, weak hull impact bearing capacity, etc., to simplify installation and disassembly steps, reduce self-weight, and shorten manufacturing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

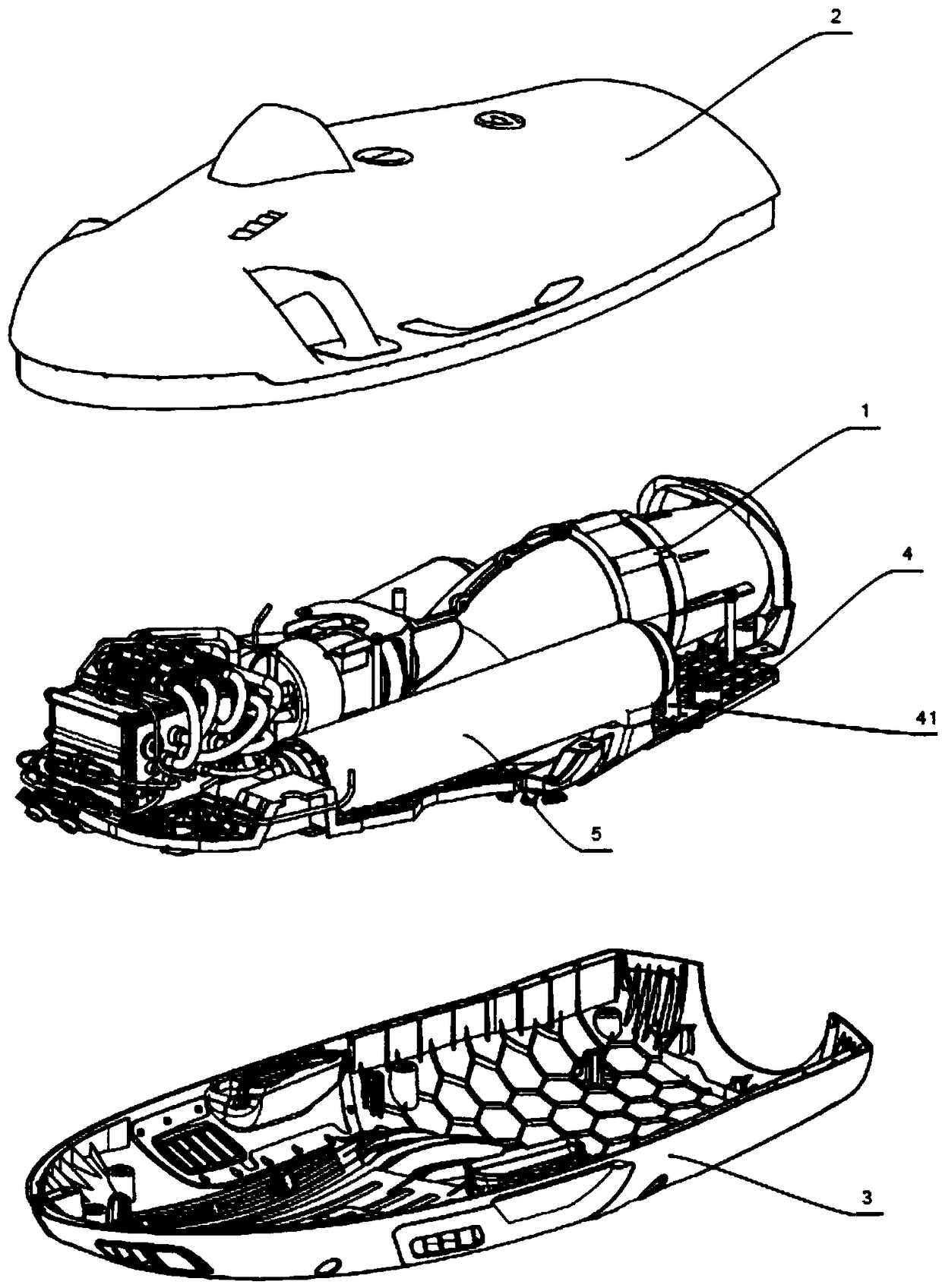

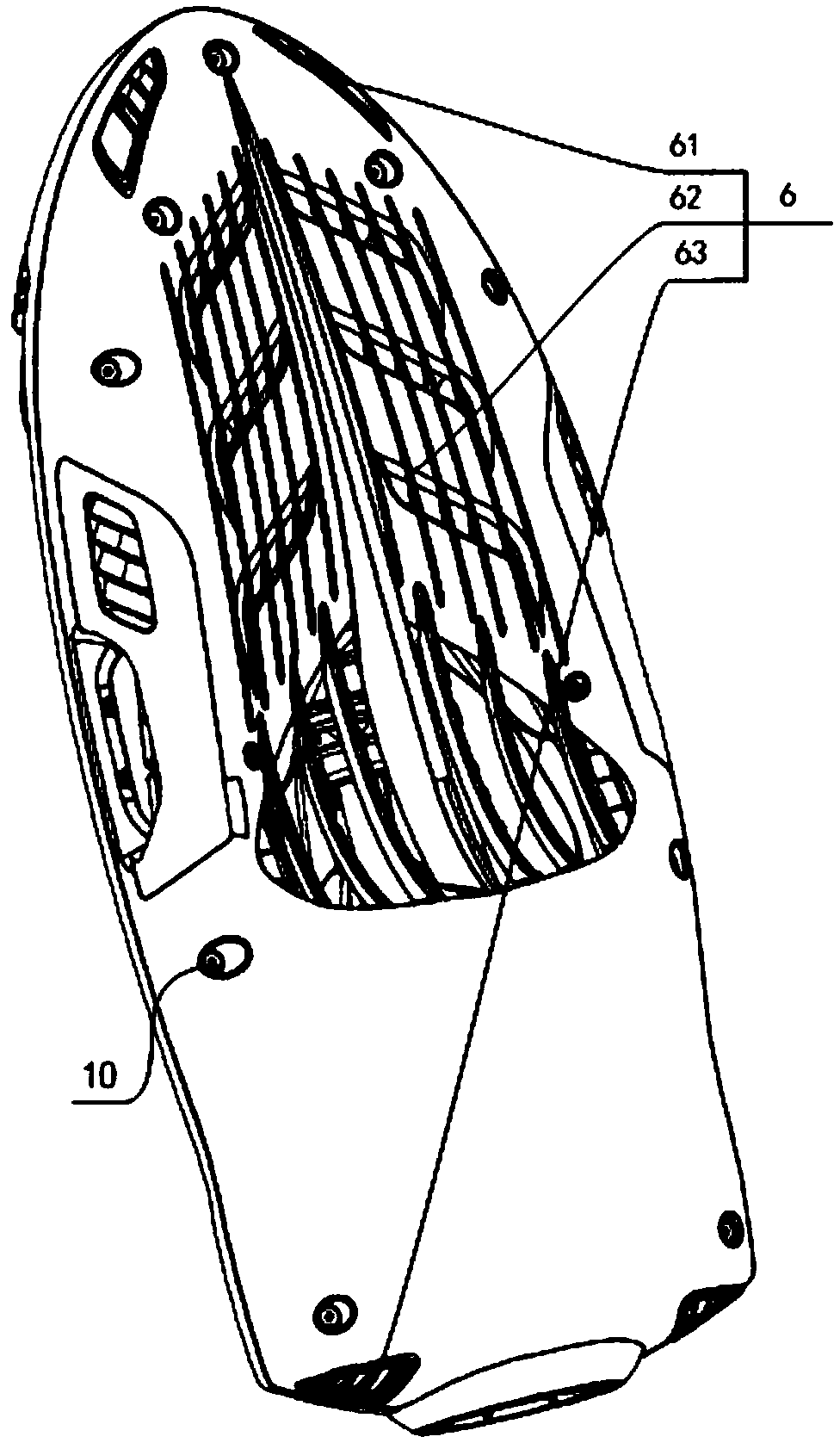

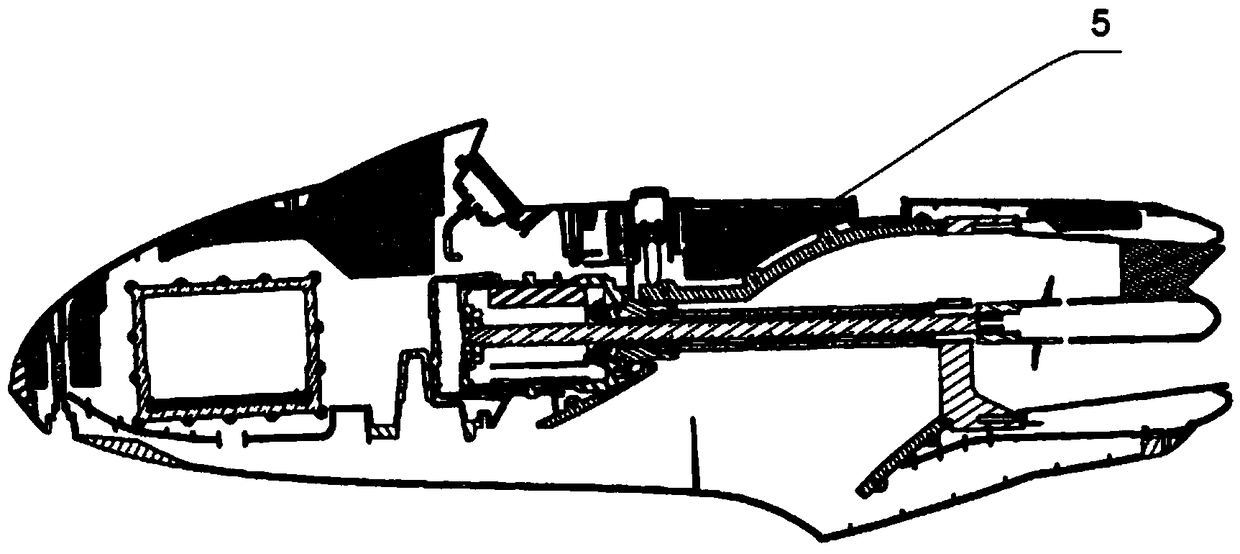

[0040] The electrical components of the existing hull are often fixedly connected. Even if there is a problem with a small part, it needs to be dismantled and overhauled as a whole, which makes the maintenance operation difficult and the cost is extremely high. In addition, the batteries, Most of the electronic components such as the controller are scattered on the shell, which is not convenient for repair and maintenance. The rigid impact caused serious damage to the hull and electrical components, and even endangered the driver's health and life safety. Based on the above reasons, the application provides an improved hull, such as figure 1 As shown, the hull not only includes the upper shell 2 and the lower shell 3, but also includes a mounting plate 4 for placing electrical components in the hull space surrounded by the upper and lower shells, so that the electrical components can be centralized and modularized. It is arranged on the mounting plate 4 and is separated from ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap