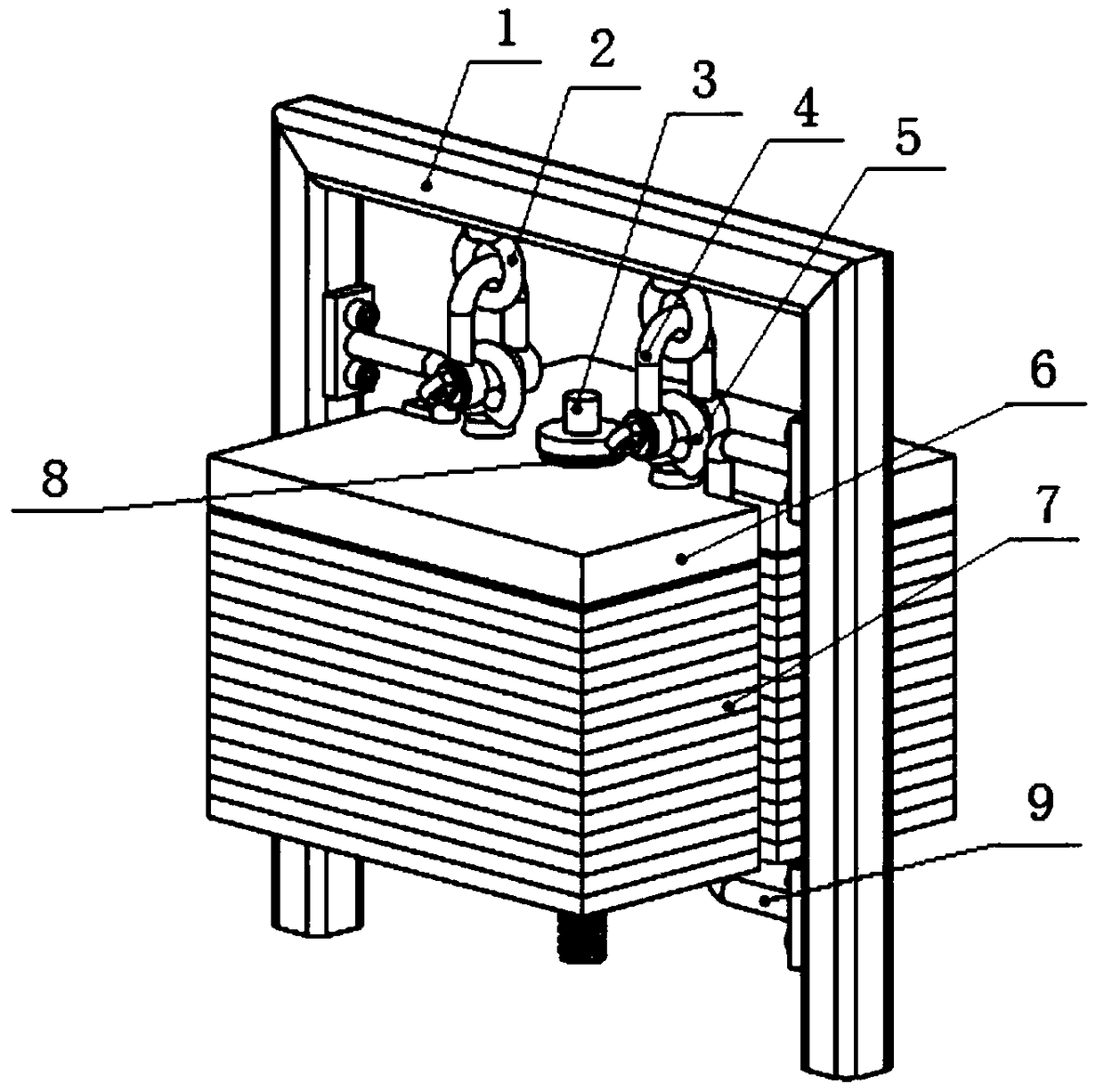

An up-floating and down-dive submerged ballast discarding device

A ballast and roof technology, applied to underwater ships, transportation and packaging, underwater operation equipment, etc., can solve the problems of increasing underwater operation risks, unbalanced submersibles, and affecting the effect of dumping, etc., to achieve low vibration , the length of demand, the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

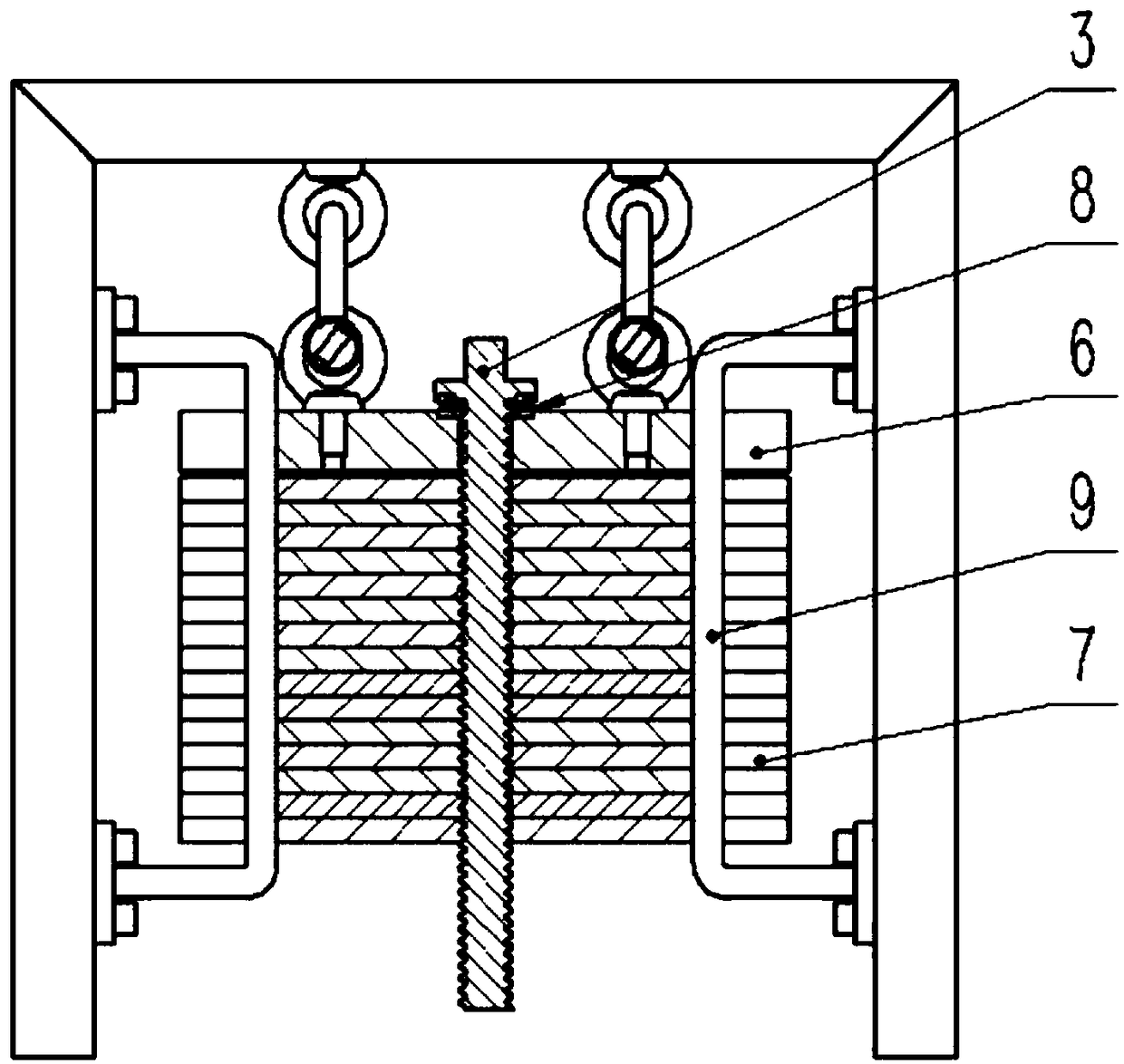

[0038] The working principle of a floating and diving ballast discarding device provided by the present invention is as follows: using the transmission and self-locking properties of the sliding screw, a plurality of weights are rotated and self-locked on the screw, and the weight and the screw are locked together. The weight is transferred to the top plate through thrust bearings and ultimately carried by the frame. When unloading, just reverse the screw, because the rotation tendency of the weight is limited by the guide rods on both sides, it can only move downward until it is discarded, and the rest of the weights are discarded in turn, and the discarding process is continuous. Since the weight of a single piece is significantly less than the weight of the entire ballast, it has less impact on the submersible. Part of it is used as ballast for diving, and the rest is used as ballast for floating. The transition between the two allows for a moderately low monoblock weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com