A kind of silicate-based red fluorescent powder for LED and preparation method thereof

A red phosphor, silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as cold color temperature, achieve good matching, good thermal stability, and improve color purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

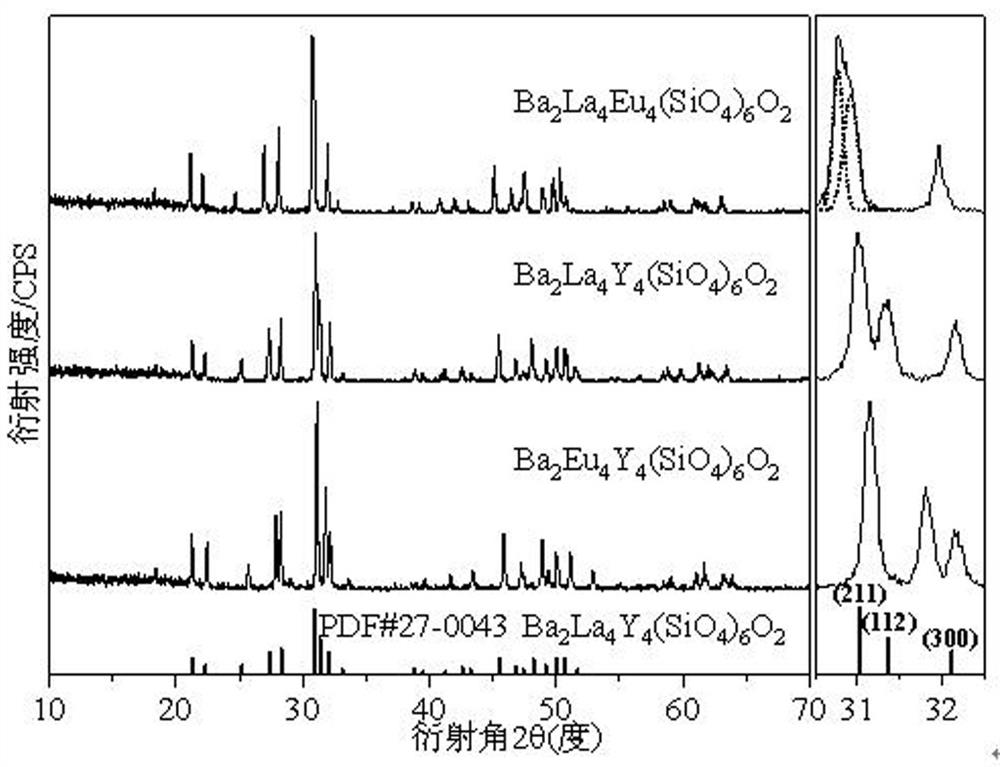

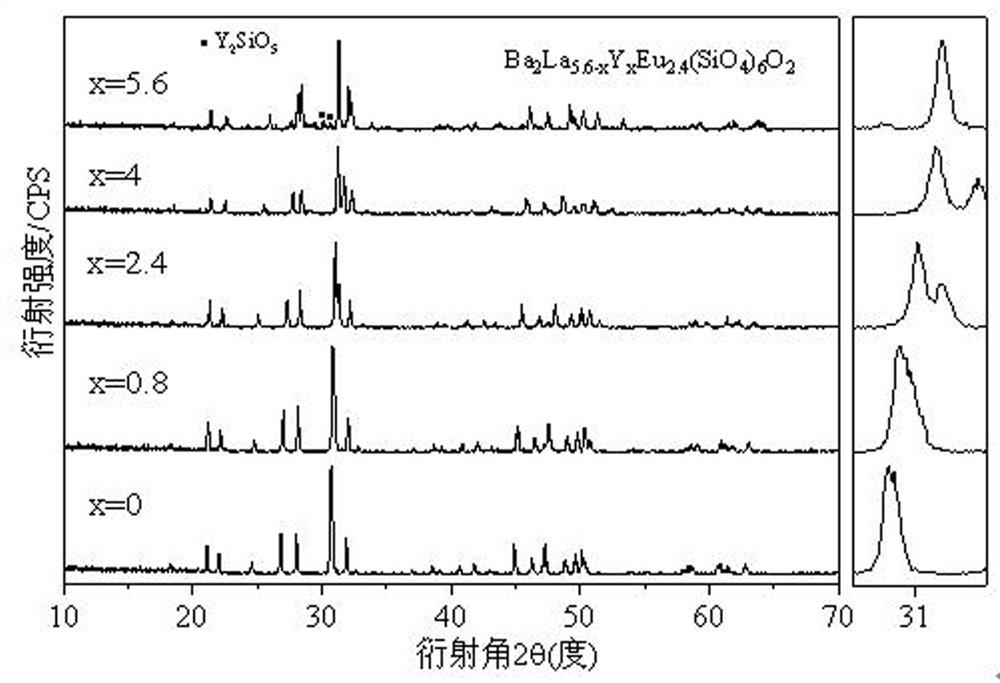

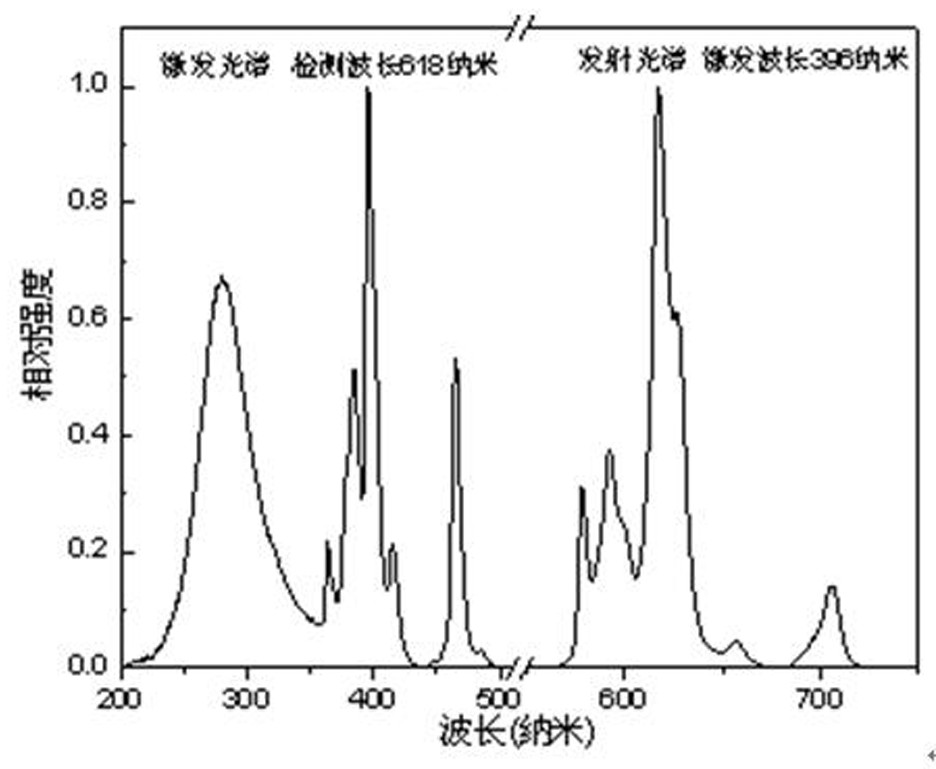

Method used

Image

Examples

Embodiment 1

[0023] When x=0.5, y=0.45, the chemical formula of red phosphor is Ba 2 La 4 Y 3.6 Eu 0.4 (SiO 4 ) 6 o 2According to the stoichiometric ratio of each element in the chemical formula, weigh 0.631g of barium carbonate, 1.043g of lanthanum oxide, 0.650g of yttrium oxide, 0.113g of europium oxide, and 0.577g of silicon oxide; put the weighed raw materials into an agate mortar and grind After 0.5 hours, a uniform mixture is obtained. Put the obtained mixture into a dry corundum crucible, put the crucible into a muffle furnace, and heat treat it in an air atmosphere. The heat treatment system is: heat up from room temperature at a rate of 3°C / min To 1450°C, keep it warm for 6h, cool naturally with the furnace to obtain a block product, and grind the block product to obtain the final Ba 2 La 4 Y 3.6 Eu 0.4 (SiO 4 ) 6 o 2 Red phosphor, the chromaticity coordinates of the red phosphor are (0.6293, 0.3685).

Embodiment 2

[0025] When x=0.5, y=0.4, the chemical formula of red phosphor is Ba 2 La 3.2 Y 4 Eu 0.8 (SiO 4 ) 6 o 2 According to the stoichiometric ratio of each element in the chemical formula, weigh 0.631g of barium carbonate, 0.834g of lanthanum oxide, 0.723g of yttrium oxide, 0.225g of europium oxide, and 0.577g of silicon oxide; put the weighed raw materials into an agate mortar and grind After 1 hour, a uniform mixture was obtained. Put the obtained mixture into a dry corundum crucible, put the crucible into a muffle furnace, and heat treat it under an air atmosphere. To 1450°C, keep it warm for 7 hours, cool naturally with the furnace to obtain a block product, and grind the block product to obtain the final Ba 2 La 3.2 Y 4 Eu 0.8 (SiO 4 ) 6 o 2 Red phosphor, the chromaticity coordinates of the red phosphor are (0.64, 0.3596).

Embodiment 3

[0027] When x=0.35, y=0.5, the chemical formula of red phosphor is Ba 2 La 4 Y 2.8 Eu 1.2 (SiO 4 ) 6 o 2 According to the stoichiometric ratio of each element in the chemical formula, weigh 0.631g of barium carbonate, 1.043g of lanthanum oxide, 0.506g of yttrium oxide, 0.338g of europium oxide, and 0.577g of silicon oxide; put the weighed raw materials into an agate mortar and grind After 0.5 hours, a uniform mixture is obtained. Put the obtained mixture into a dry corundum crucible, put the crucible into a muffle furnace, and heat treat it in an air atmosphere. The heat treatment system is: heat up from room temperature at a rate of 5°C / min to 1500°C, keep it warm for 8 hours, and cool naturally with the furnace to obtain a block product, and grind the block product to obtain the final Ba 2 La 4 Y 2.8 Eu 1.2 (SiO 4 ) 6 o 2 Red phosphor, the chromaticity coordinates of the red phosphor are (0.6371, 0.3619).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com