Wide band ultraviolet excitation green luminous material and its preparation method

A luminescent material, green technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as difficulties, and achieve the effects of simple and easy production process, stable chemical and optical properties, and cheap and easily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

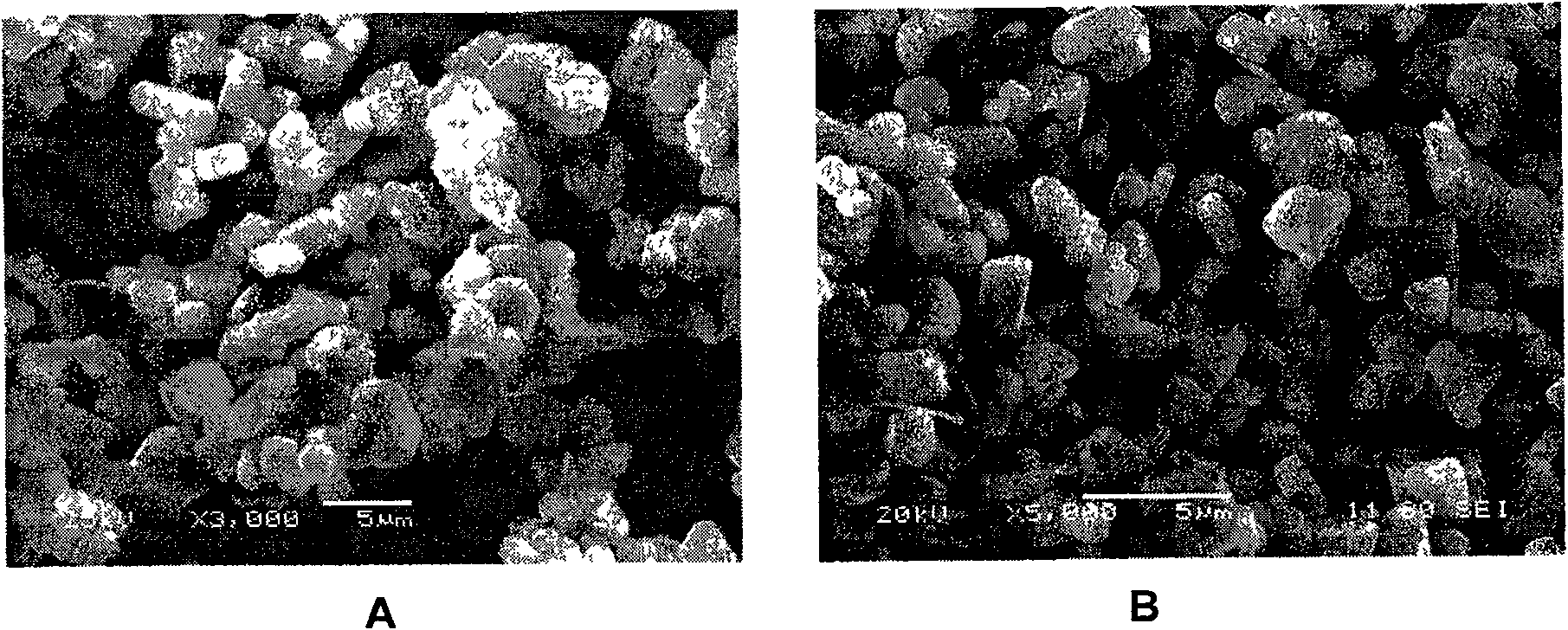

[0019] Weigh 0.02mol ZnS and 0.002mol KCl and grind and mix them in a fume hood to obtain a precursor, put the above precursor in a muffle furnace for sintering at 800°C for 1 hour, and then grind a little to obtain a broadband ultraviolet-excited green luminescent material. The composition determined by energy dispersive X-ray spectroscopy is: ZnO:xS:yCl, x=0.003, y=0.007. Electron microscope picture as figure 2 As shown, its average particle size is 1-5um.

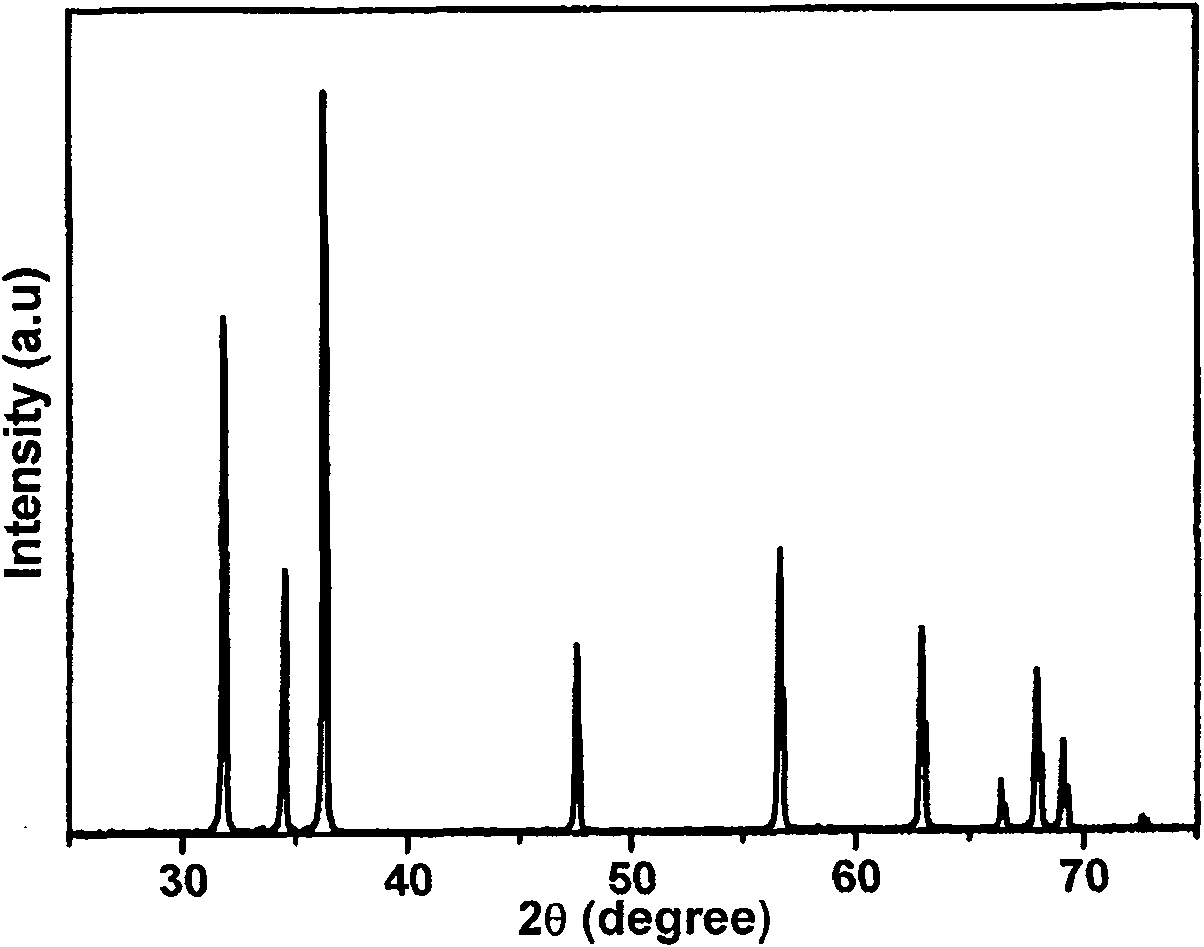

[0020] XRD picture as shown image 3 As shown, the results show that the main phase of the sample is ZnO, that is, the luminescent material is based on ZnO. Test conditions: voltage 40kV, current 40mA, scanning speed 8° / min.

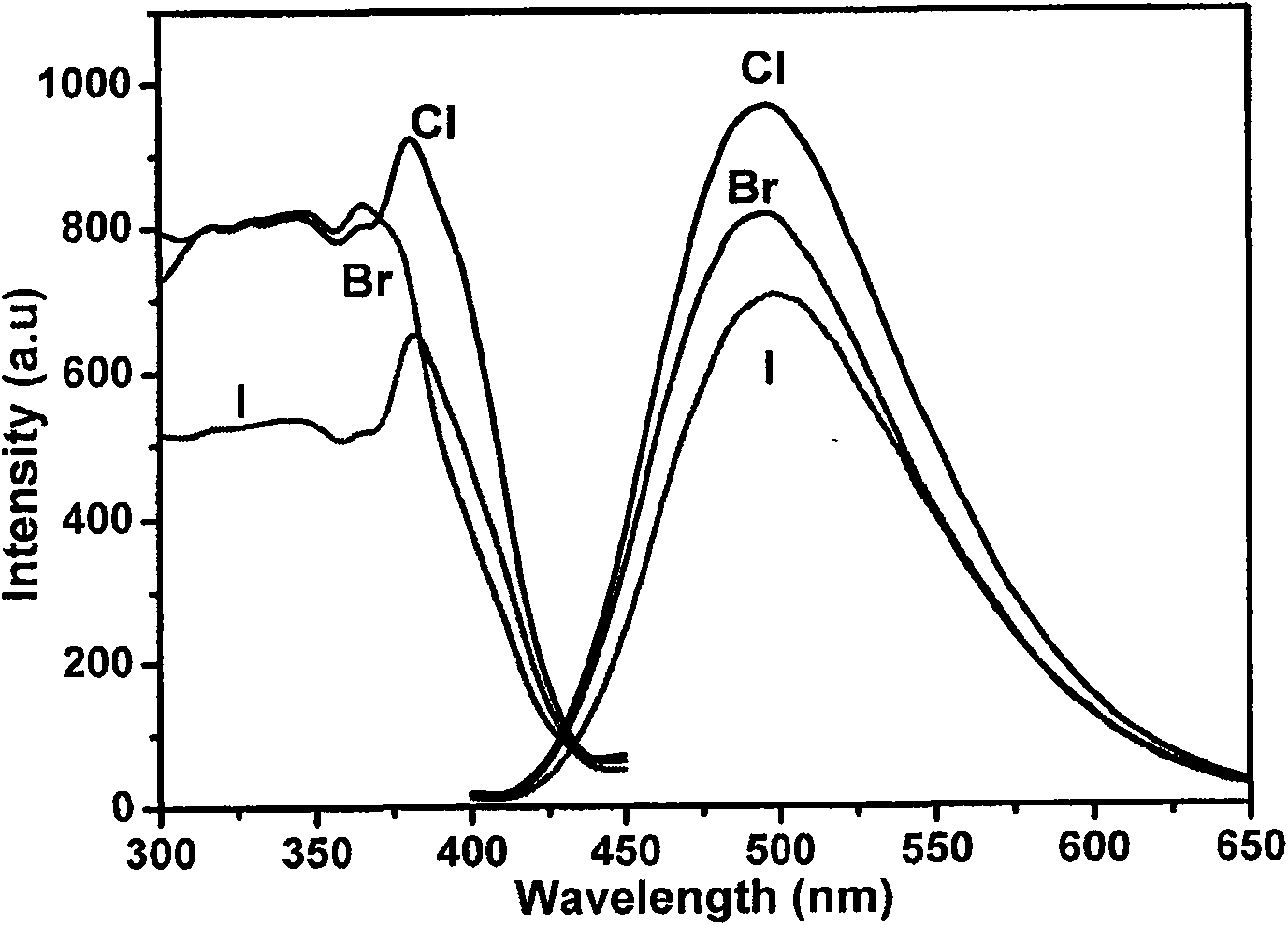

[0021] Fluorescence test pattern such as figure 1 As shown, the results show that the luminescent material has a strong absorption in the long-wave ultraviolet region of 300-430nm, and a strong emission in the 450-600nm. Test condition: λ ex =380nm,λ em =496nm, slit width 5nm, voltage 480V,...

Embodiment 2

[0023] Weigh 0.02mol ZnS and 0.001mol KBr and grind and mix them in a fume hood to obtain the precursor, put the above precursor in a muffle furnace for sintering at 800°C for 1 hour, and then grind slightly to obtain a green luminescent material excited by broadband ultraviolet light. The composition determined by energy dispersive X-ray spectroscopy is: ZnO:xS:yBr, x=0.002, y=0.002. The average particle size is 1-5um.

Embodiment 3

[0025] Weigh 0.02mol ZnS and 0.002mol KI and grind and mix them in a fume hood to obtain a precursor. Put the above precursors in a muffle furnace for sintering at 700°C for 2 hours, and then grind a little to obtain a green luminescent material excited by broadband ultraviolet rays. The composition determined by energy dispersive X-ray spectroscopy is: ZnO:xS:yl, x=0.007, y=0.005. The average particle size is 1-5um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com