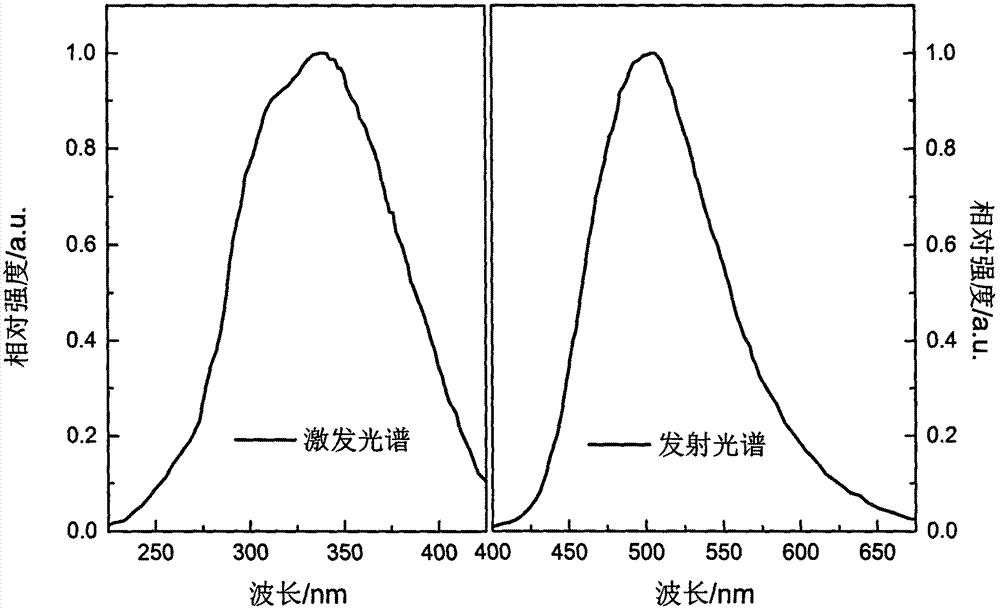

Green fluorescent powder for LED and preparation method of green fluorescent powder

A green phosphor, phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor matching and low luminous intensity, and achieve the effect of good matching and high commercial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 7.93mol CaCO according to the general chemical formula 3 , 1.5mol La 2 o 3 , 3mol SiO 2 , 3mol NH 4 h 2 PO 4 , 0.035mol Eu 2 o 3 , as a raw material, put the raw material in a ball mill jar, mix evenly, and ball mill for 6 hours at a ball milling speed of 125 rpm, then in N 2 / H 2 Calcined under the reducing atmosphere created by the mixed gas, where N 2 and H 2 The flow ratio is 9:1, the calcination temperature is 1350°C, and the calcination time is 6 hours. After the calcination, the material is taken out, cooled and pulverized, and ground and sieved to obtain the required Ca 7.93 La 3 (SiO 4 ) 3 (PO 4 ) 3 o 2 : 0.07Eu 2+ Green phosphor material.

Embodiment 2

[0019] Weigh 7.999mol SrCO according to the general chemical formula 3 , 1.5mol La 2 o 3 , 3mol SiO 2 , 3molNH 4 h 2 PO 4 , 0.0005mol Eu 2 o 3 , as a raw material, put the raw material in a ball mill jar, mix evenly, and ball mill for 5 hours at a ball milling speed of 160 rpm, then in N 2 / H 2 Calcined under the reducing atmosphere created by the mixed gas, where N 2 and H 2 The flow ratio is 10:1, the calcination temperature is 1450°C, and the calcination time is 7 hours. After the calcination, the material is taken out, cooled and pulverized, and ground and sieved to obtain the required Sr 7.999 La 3 (SiO 4 ) 3 (PO 4 ) 3 o 2 : 0.001Eu 2+ Green phosphor material.

Embodiment 3

[0021] Weigh 7.5mol BaCO according to the general chemical formula 3 , 1.5mol La 2 o 3 , 3mol SiO 2 , 3mol NH 4 h 2 PO 4 , 0.25mol Eu 2 o 3 , as a raw material, put the raw material in a ball mill jar, mix evenly, and ball mill for 10 hours at a ball milling speed of 110 rpm, then in N 2 / H 2 Calcined under the reducing atmosphere created by the mixed gas, where N 2 and H 2 The flow ratio is 8:1, the calcination temperature is 1200°C, and the calcination time is 9 hours. After the calcination, the material is taken out, cooled and pulverized, and ground and sieved to obtain the desired Ba 7.5 La 3 (SiO 4 ) 3 (PO 4 ) 3 o 2 : 0.5Eu 2+ Green phosphor material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com