Easily-cleanable rust-proof knitting machine oil and preparation method thereof

A knitting machine oil and easy-to-clean technology, applied in the field of knitting machine oil, to achieve the effect of not being easy to age, not affecting product performance, and the oil is transparent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is further explained. These examples are to make the technical solutions of the present invention clearer to those skilled in the art, rather than to limit the present invention.

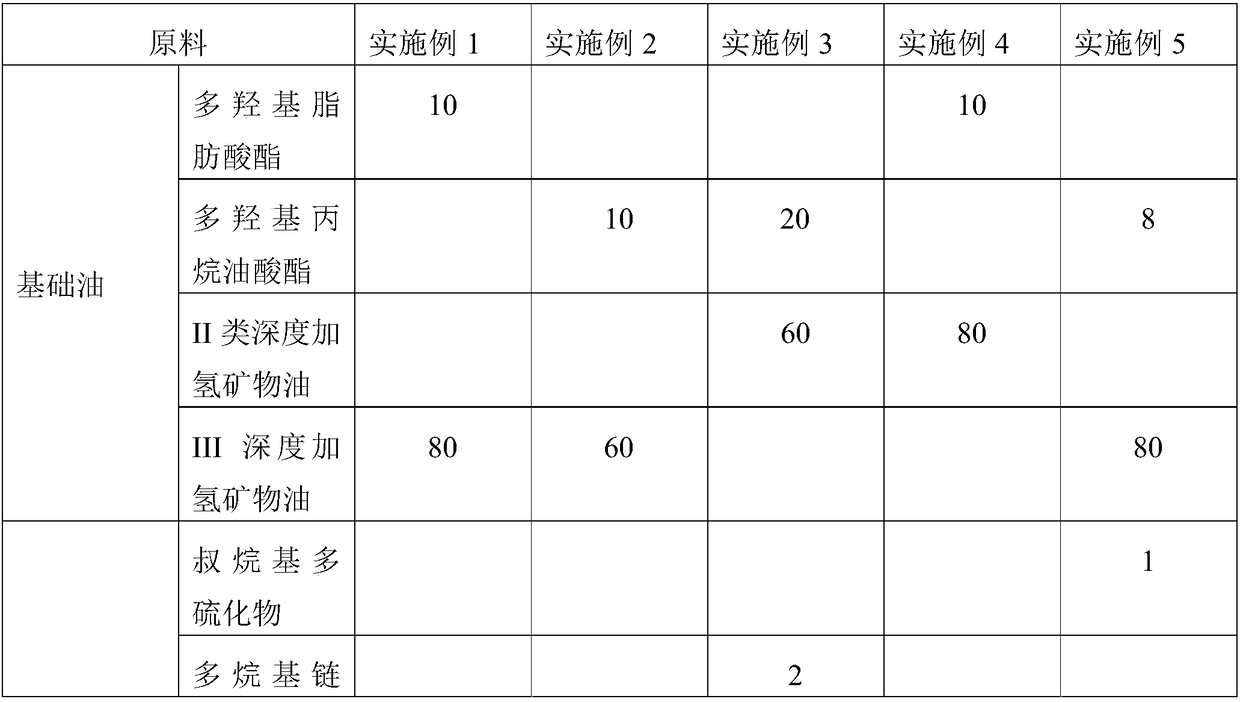

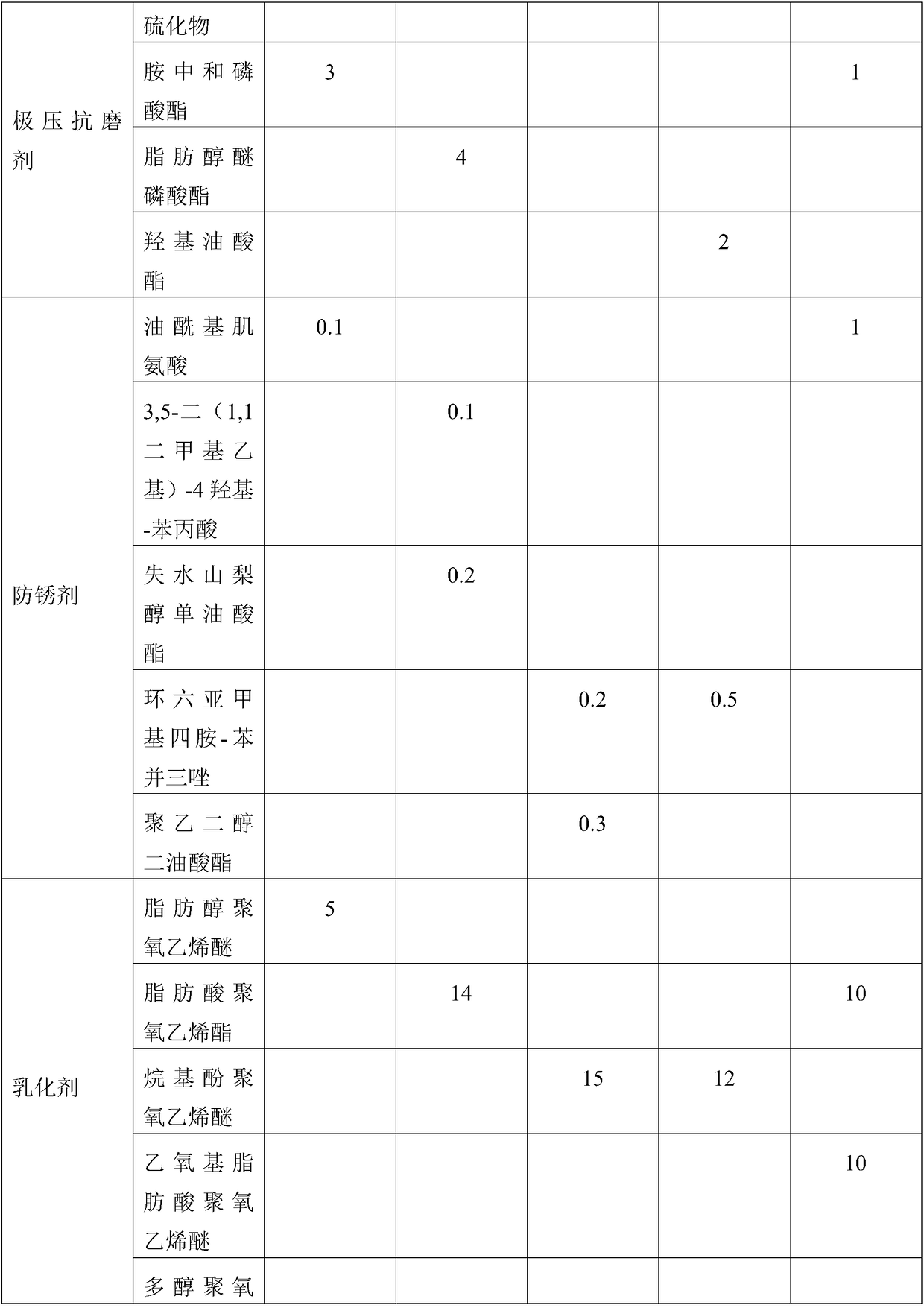

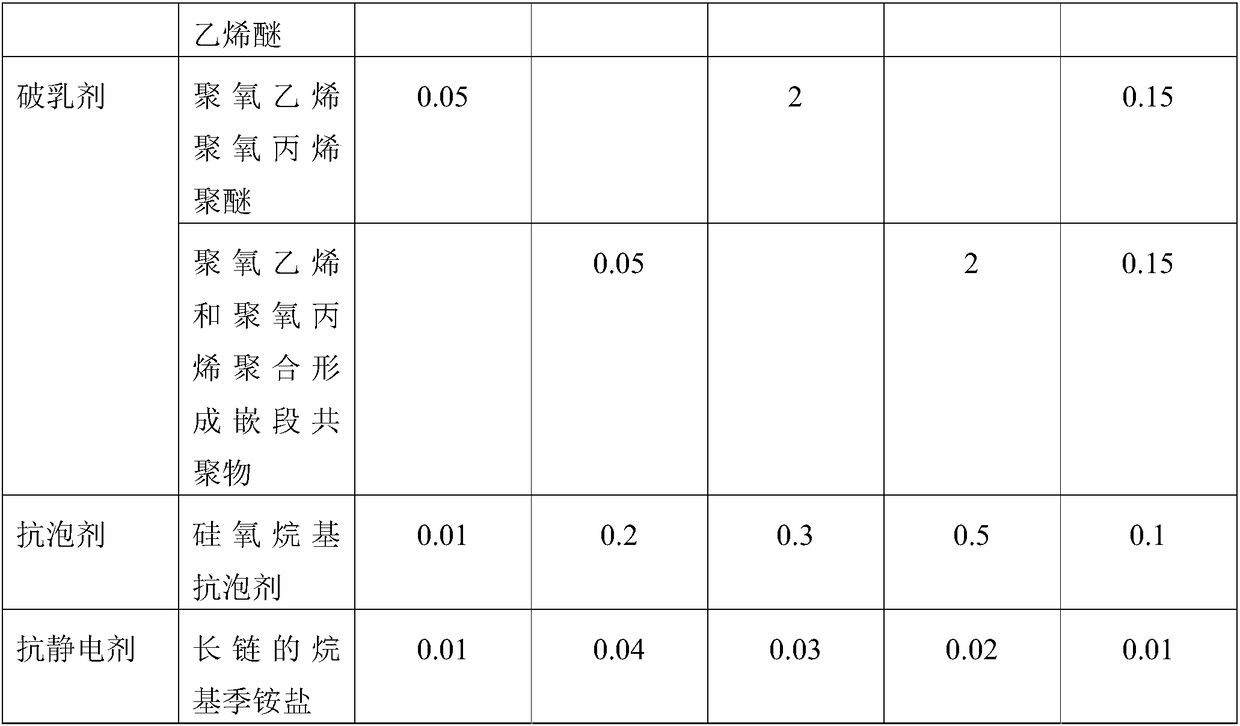

[0029] Table 1: Embodiments 1 to 5 (unit: parts by weight)

[0030]

[0031]

[0032]

[0033] The preparation process is as follows:

[0034] (1) Weigh each component according to the proportion, heat the base oil to 40-50°C, keep it warm, and set aside;

[0035] (2) Add anti-foaming agent and extreme pressure anti-wear agent to the resultant of step (1) while stirring, and dissolve completely;

[0036] (3) Add 99% emulsifier, antirust agent and antistatic agent to the resultant of step (2), lower the temperature to below 35°C, stop stirring, and prepare mixture A;

[0037] (4) According to system balance adjustment, add the remaining emulsifier and demulsifier to the mixture A to ensure that the system is uniform, clear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com