Low grade substrate treatment heavy duty epoxy primer

A technology of substrate treatment and epoxy primer, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of unreachable steel surface, inconvenient sand blasting and rust removal, and unreachable grades. Ensure long-term anti-corrosion, anti-corrosion construction is simple and easy, and the spherical shape is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The low-grade substrate treatment heavy-duty epoxy primer provided by the present invention will be further described in detail below through specific examples, but the present invention is not limited to the following preferred examples.

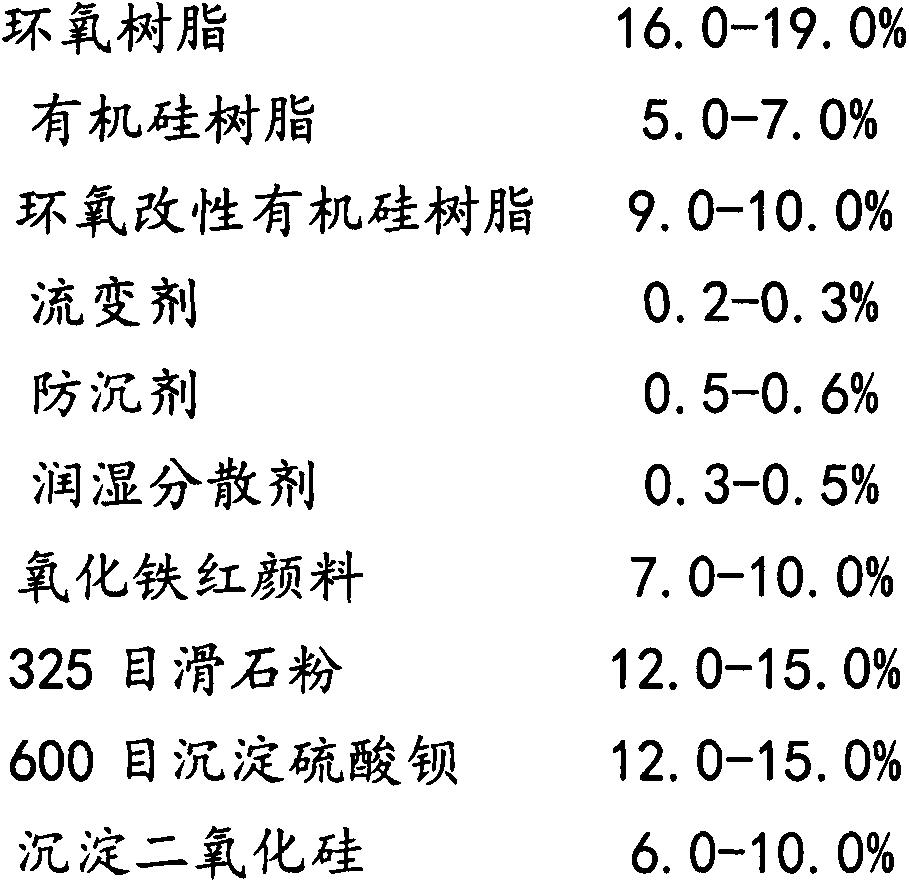

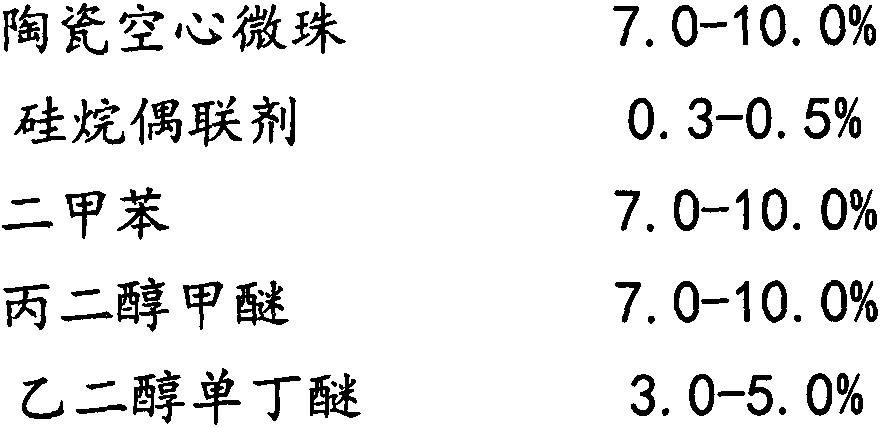

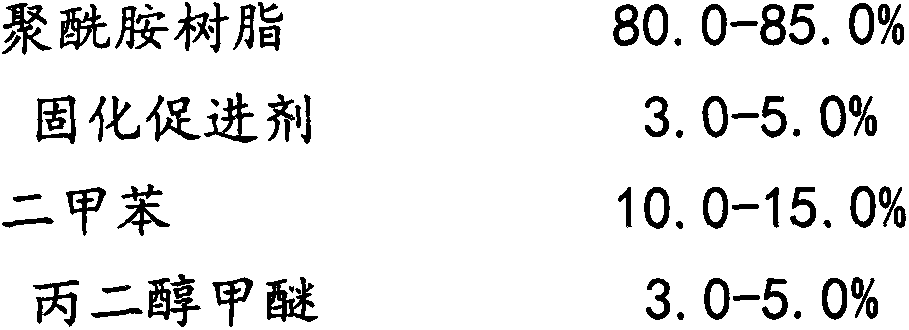

[0039] (1) Main paint components (weight) in the heavy-duty anti-corrosion epoxy primer for low-grade substrate treatment:

[0040]

[0041] The epoxy resin adopts KD-175LX90 of KUKDO Company; the organic silicon resin adopts the methyl phenyl group (ratio 3:2) organic silicon resin (SY409 of Weikai Company of Germany) with a solid content of 60%; the epoxy modified organic silicon resin Adopt the bisphenol A epoxy resin modification 20% of the bisphenol A epoxy resin of the equivalent of 50% of the solid content 240 (XSJ-163 of Guangzhou Xingshengjie Company); The rheological agent adopts the polyamide rheological agent that contains 20% solidly (6900-20X from Japanese DISPARLON company); the anti-settling agent adopts polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com