A method for reducing green taste in wine during fermentation

A fermentation process, red wine technology, applied in the field of wine, can solve the problems of affecting the flavor of wine, taste and quality of wine, so as to improve the overall quality level, easy to operate, and relieve the effect of greening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

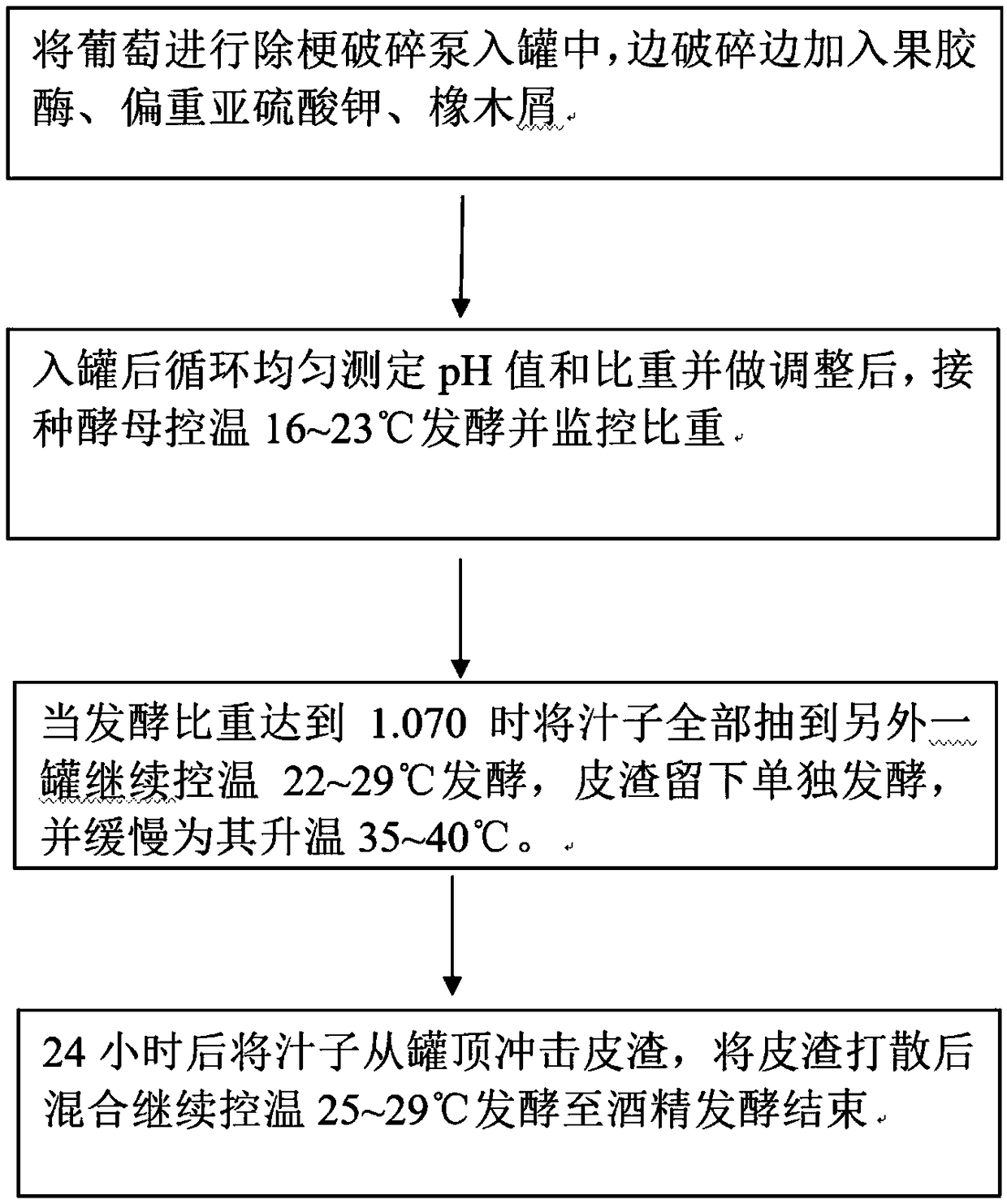

Method used

Image

Examples

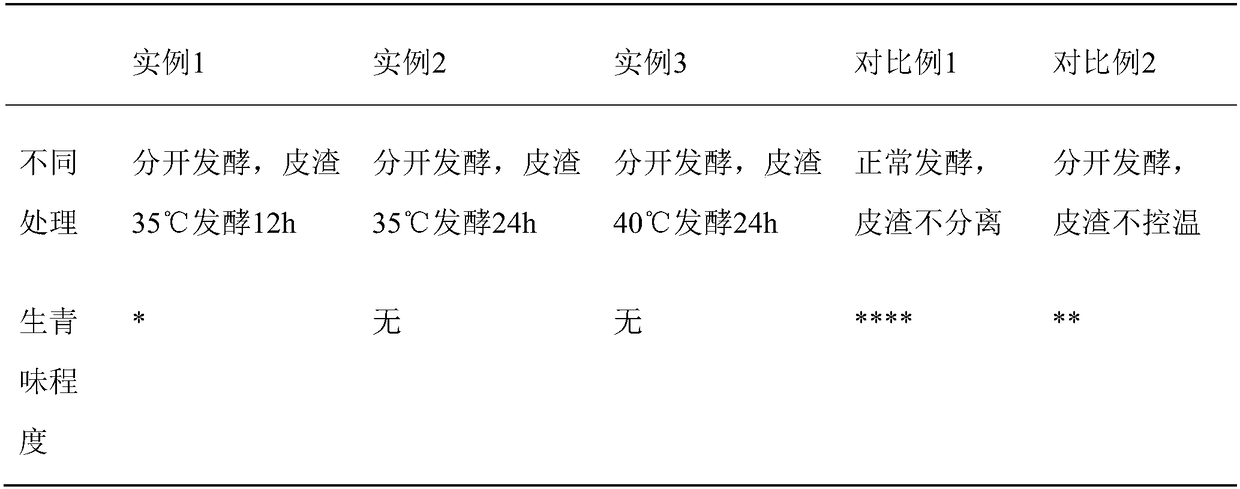

Embodiment 1

[0035] Embodiment 1 provides a method for reducing green taste of red wine during fermentation.

[0036] S1: Destemming and crushing the picked grapes, adding 40 mg / L of pectinase, 60 mg / L of sulfur dioxide, and 2 g / L of natural oak chips.

[0037] S2: After entering the tank, the pH value and specific gravity are uniformly measured and adjusted, and the pH value is adjusted to 3.5-3.7, and the target alcohol content is 12%vol-13.5%vol. Inoculate yeast 0.2g / L at 16°C. Add 0.2g / L organic nitrogen source when the specific gravity drops by 10 points. Control the fermentation temperature at 16°C to 23°C, and gradually increase the fermentation temperature as the fermentation progresses.

[0038] S3: When the specific gravity of the fermentation reaches 1.070, all the juice is pumped into another tank in an open manner to continue the temperature-controlled fermentation at 22-29°C, and the dregs are left for separate fermentation, and the temperature is slowly raised to 35°C. Mo...

Embodiment 2

[0041] Example 2 provides a method for reducing the green taste of red wine during fermentation.

[0042] S1: Destemming and crushing the picked grapes, adding 40 mg / L of pectinase, 60 mg / L of sulfur dioxide, and 2 g / L of natural oak chips.

[0043] S2: After entering the tank, the pH value and specific gravity are uniformly measured and adjusted, and the pH value is adjusted to 3.5-3.7, and the target alcohol content is 12%vol-13.5%vol. Inoculate yeast 0.2g / L at 16°C. Add 0.2g / L organic nitrogen source when the specific gravity drops by 10 points. Control the fermentation temperature at 16°C to 23°C, and gradually increase the fermentation temperature as the fermentation progresses.

[0044] S3: When the specific gravity of the fermentation reaches 1.070, all the juice is pumped into another tank in an open manner to continue the temperature-controlled fermentation at 22-29°C, and the dregs are left for separate fermentation, and the temperature is slowly raised to 35°C. M...

Embodiment 3

[0047] Example 3 provides a method for reducing the green taste of red wine during fermentation.

[0048] S1: Destemming and crushing the picked grapes, adding 40 mg / L of pectinase, 60 mg / L of sulfur dioxide, and 2 g / L of natural oak chips.

[0049] S2: After entering the tank, the pH value and specific gravity are uniformly measured and adjusted, and the pH value is adjusted to 3.5-3.7, and the target alcohol content is 12%vol-13.5%vol. Inoculate yeast 0.2g / L at 16°C. Add 0.2g / L organic nitrogen source when the specific gravity drops by 10 points. Control the fermentation temperature at 16°C to 23°C, and gradually increase the fermentation temperature as the fermentation progresses.

[0050] S3: When the specific gravity of the fermentation reaches 1.070, all the juice is pumped into another tank in an open manner to continue the temperature-controlled fermentation at 22-29°C, and the dregs are left for separate fermentation, and the temperature is slowly raised to 40°C. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com