Method for processing cinnamon-flavored black tea from cinnamon bark

A technology of cinnamon bark and fragrant black tea, which is applied in the directions of tea spice, tea treatment before extraction, etc., can solve the problems of low aroma, low selling price and low quality, and achieve the effects of unique aroma, improved quality, sweet and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

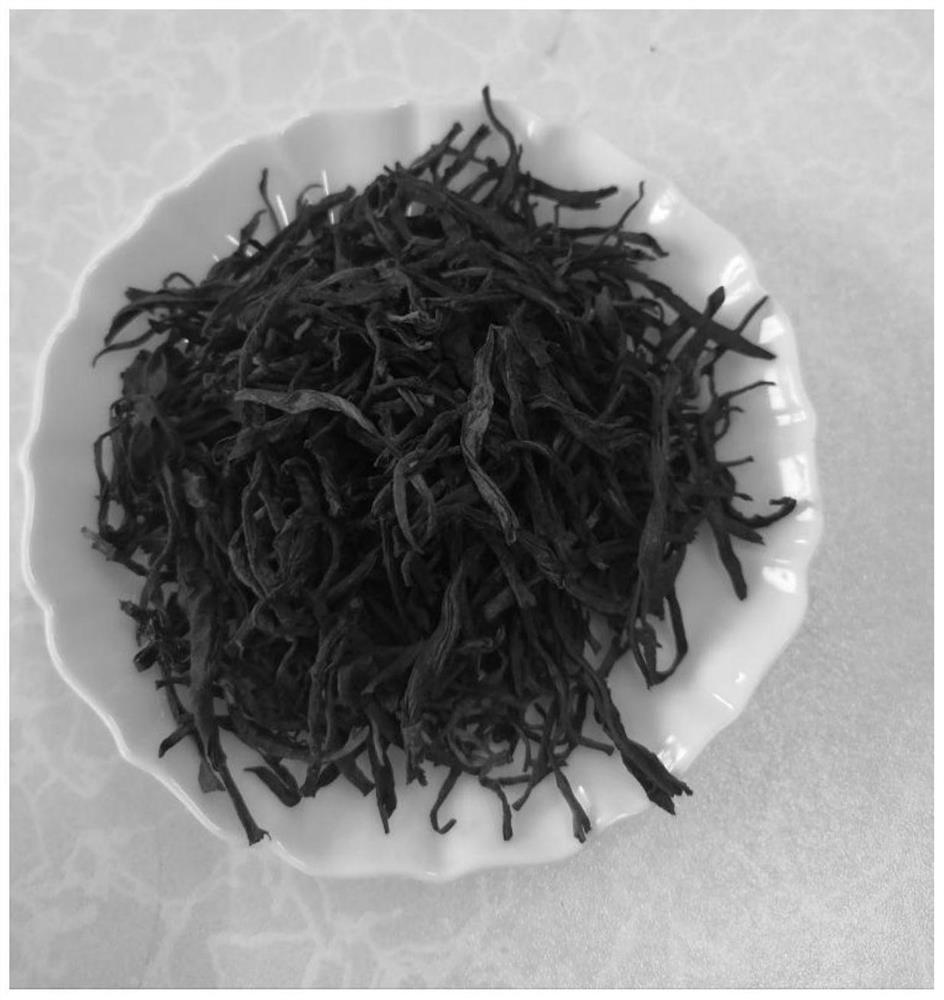

Image

Examples

Embodiment 1

[0045] A method for processing cinnamon-scented black tea with cinnamon bark, comprising the following steps:

[0046] (1) Picking of fresh leaves: the summer fresh leaves with tenderness of one bud, one and two leaves of Yunnan big-leaf tea tree varieties are used as raw materials;

[0047] (2) Withering: spread the picked fresh leaves thinly, the thickness of the leaves is 2cm, let the leaves slowly reduce water and become soft, control the water loss rate of withering at 62%, and wither until the color of the fresh leaves changes from bright green to dark Green, the leaves are soft, can be held in a ball, not easy to scatter when loosened, and the tender stems are constantly broken;

[0048] (3) Shaking green: put the withered leaves into the green shaking machine for shaking green, the rotating speed is 12r / min, the time is 5min, then put it into the green stand room, keep the temperature at 22°C, stand green for 2 hours, the degree of shaking is destruction Leaf edge cel...

Embodiment 2

[0058] A method for processing cinnamon-scented black tea with cinnamon bark, comprising the following steps:

[0059] (1) Picking of fresh leaves: the summer fresh leaves with tenderness of one bud, one and two leaves of Yunnan big-leaf tea tree varieties are used as raw materials;

[0060] (2) Withering: Spread the picked fresh leaves thinly. The thickness of the leaves is 1cm, so that the leaves slowly reduce water and become soft. The water loss rate of withering is controlled at 64%. Wither until the color of the fresh leaves changes from bright green to dark Green, the leaves are soft, can be held in a ball, not easy to scatter when loosened, and the tender stems are constantly broken;

[0061] (3) Shaking green: put the withered leaves into the green shaking machine for shaking green, the rotating speed is 10r / min, the time is 5min, then put it into the green stand room, keep the temperature at 22°C, stand green for 1h, the degree of shaking green is destruction Leaf e...

Embodiment 3

[0071] A method for processing cinnamon-scented black tea with cinnamon bark, comprising the following steps:

[0072] (1) Picking of fresh leaves: the summer fresh leaves with tenderness of one bud, one and two leaves of Yunnan big-leaf tea tree varieties are used as raw materials;

[0073] (2) Withering: Spread the picked fresh leaves thinly. The thickness of the leaves is 2cm, so that the leaves slowly reduce water and become soft. The water loss rate of withering is controlled at 60%. Wither until the color of the fresh leaves changes from bright green to dark Green, the leaves are soft, can be held in a ball, not easy to scatter when loosened, and the tender stems are constantly broken;

[0074] (3) Shaking: Put the withered leaves into the green shaking machine for shaking green, the speed is 12r / min, the time is 3min, then put it into the green stand, keep the temperature at 20°C, stand green for 2 hours, the degree of shaking is destruction Leaf edge cells, green gras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com