Purple sweet potato and fragrant tea processing method

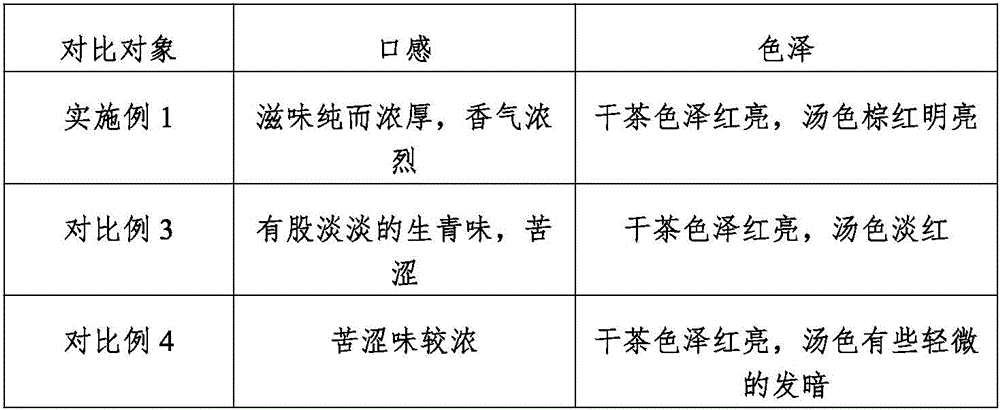

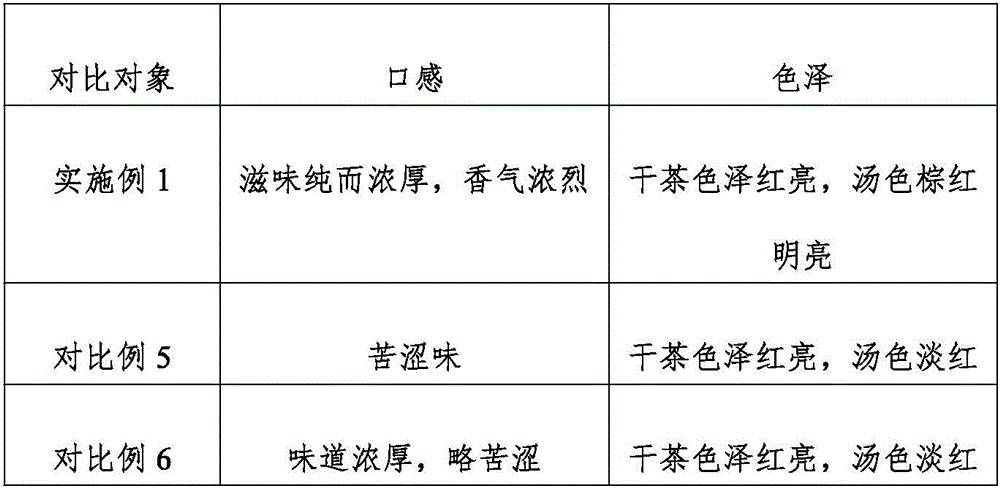

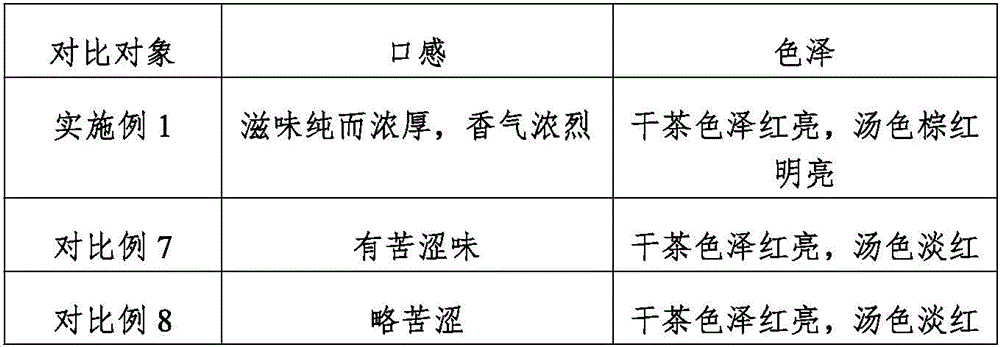

A processing method and technology of purple sweet potato, applied in tea, tea spices, tea treatment before extraction, etc., can solve the problems of incomplete fermentation, bitter taste, low economic benefit, etc., achieve sufficient enzymatic oxidation reaction, and remove raw green taste , strong aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] After picking the fresh tea leaves with one bud and two leaves or one bud and three leaves, spread them out with a thickness of 2 cm, and let them dry until the water content of the fresh leaves is 60%. By airing the fresh leaves, the water will be dispersed, showing a slight withering state, which can increase the toughness of the tea leaves; put the tea leaves after airing into the green shaking machine, and use the intermittent shaking method, the first shaking green 40min, stop the machine After 5min, carry out second shake green, the time of shake green green for the second time is 30min; Put the tealeaves after shaking green into kneading machine, first knead 60min, shut down 8min, continue to knead for the second time again, knead time is 40min; After the tea leaves are spread out for the second time, the temperature is controlled to 20°C by sprinkling water on the ground or a hair dryer, the time is 2 hours, and the thickness of the spread is 3cm; the tea leaves ...

Embodiment 2

[0024] After plucking fresh tea leaves with one bud and two leaves or one bud and three leaves, spread them out with a thickness of 4 cm, and let them dry until the water content of the fresh leaves is 65%. By airing the fresh leaves, the moisture will be distributed and the tea leaves will be in a slightly withered state, which can increase the toughness of the tea leaves; put the aired tea leaves into the shaking green machine, and use the intermittent shaking method, shake the green leaves for 60 minutes for the first time, and then stop the machine After 10min, carry out the second shaking of the green, the time of the second shaking of the green is 40min; put the tea leaves after the shaking into the kneading machine, first knead for 80min, stop the machine for 15min, and then continue the second kneading, the kneading time is 60min; After the tea leaves are spread out for the second time, the temperature is controlled to 25°C by sprinkling water on the ground or a hair dr...

Embodiment 3

[0026]After plucking fresh tea leaves with one bud and two leaves or one bud and three leaves, spread them out with a thickness of 3 cm, and let them dry until the water content of the fresh leaves is 63%. By airing the fresh leaves, the moisture will be dispersed and the tea leaves will be in a slightly withered state, which can increase the toughness of the tea leaves; put the aired tea leaves into the green shaking machine, and use the intermittent shaking method, shake the green leaves for 50 minutes for the first time, and then stop the machine After 8min, carry out second shaking green, the time of second shaking green is 35min; The tealeaves after shaking green is put into kneading machine, first knead 70min, shut down 12min, continue second kneading again, kneading time is 50min; After the tea leaves are spread out for the second time, the temperature is controlled to 22°C by sprinkling water on the ground or a hair dryer, the time is 3 hours, and the thickness of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com