Novel sleeve-type pneumatic spring with external restraint aluminum cover

A technology of air spring and aluminum cover, which is applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problems of reducing the fatigue life of air spring, not meeting the requirements of light weight, and reducing the strength of pressure ring, etc., to achieve improvement Riding comfort, obvious lightweight effect, and stable bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

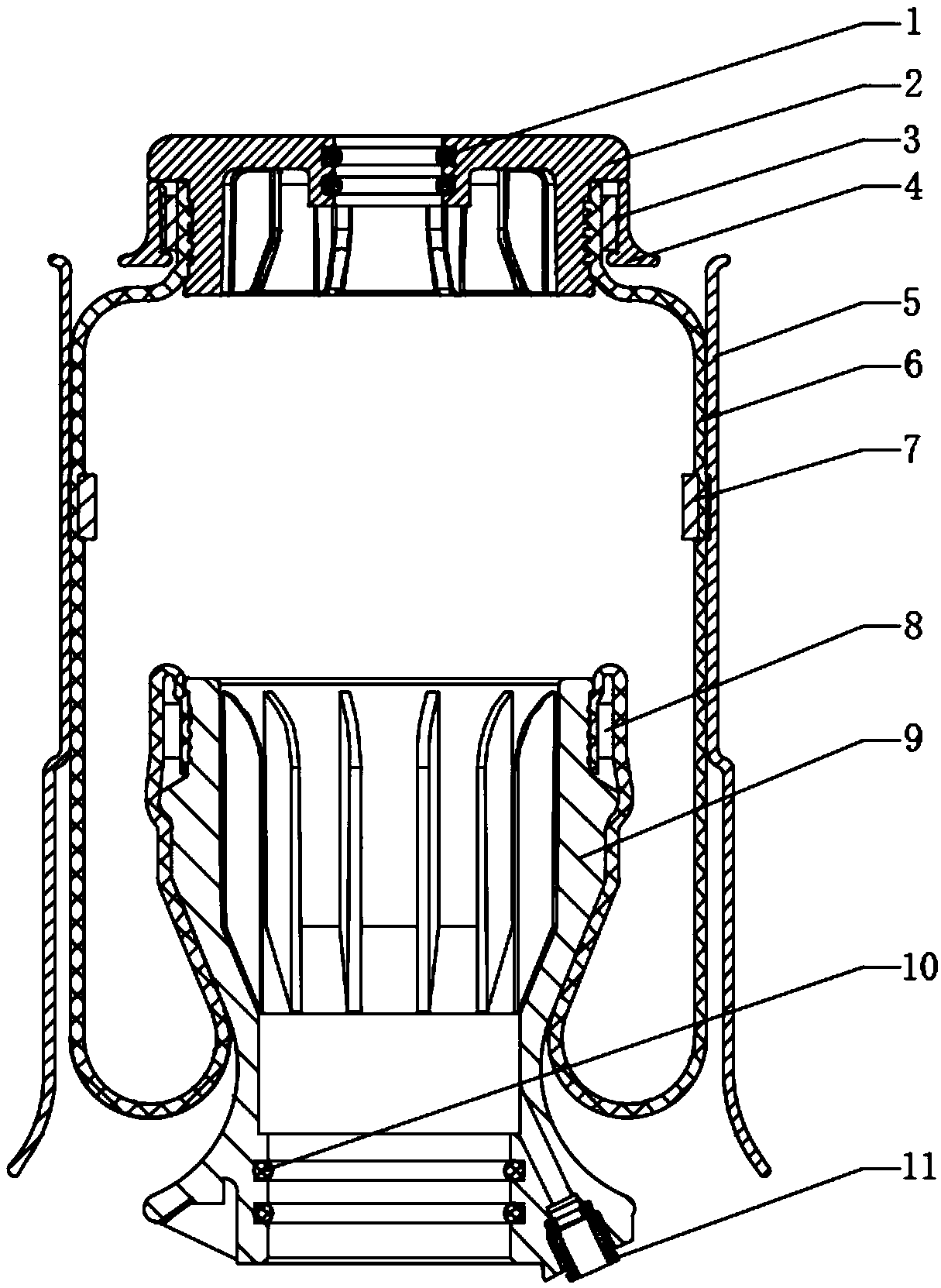

[0028] Refer below Figure 1-4 Describe in detail a new sleeve type air spring with an external restraint aluminum cover provided by the embodiment of the present invention.

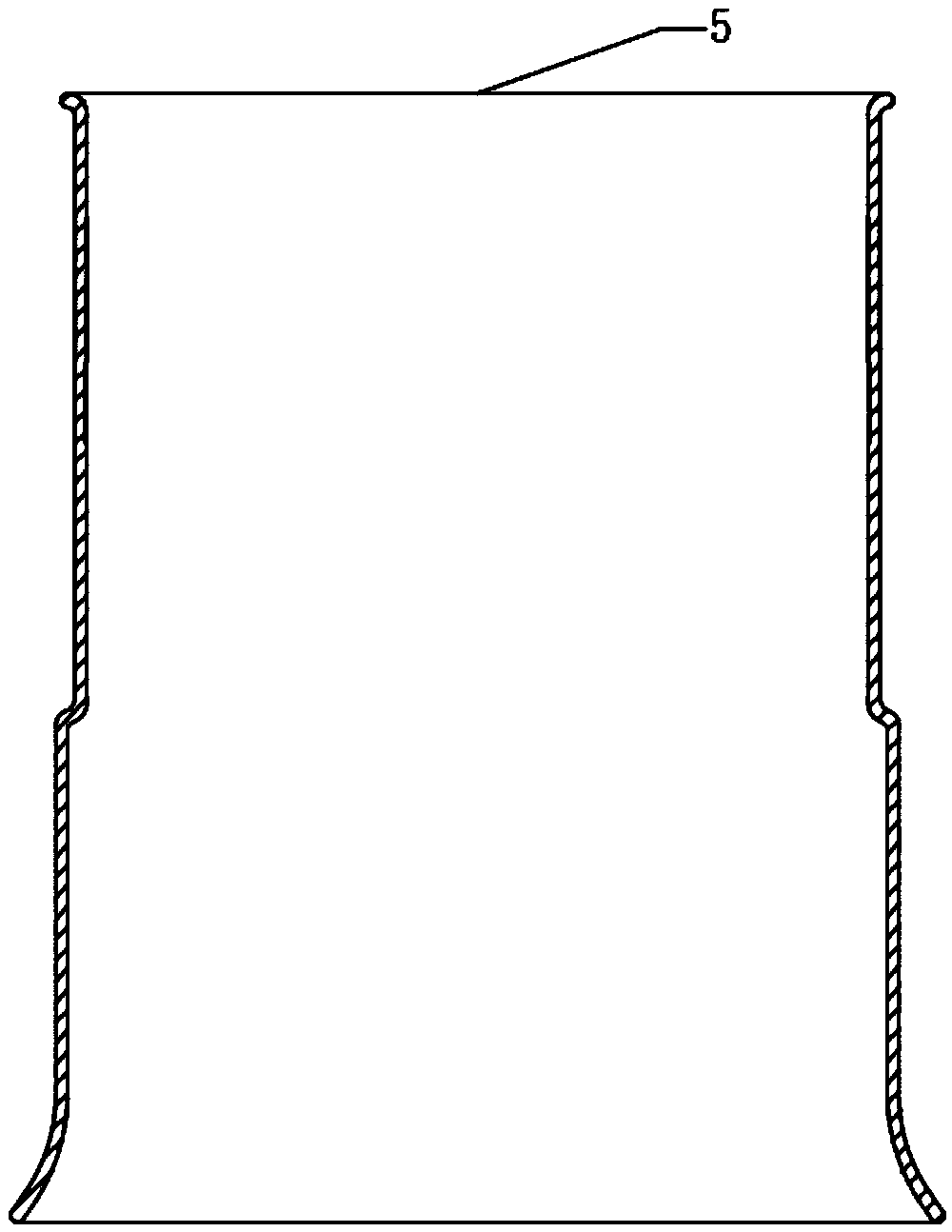

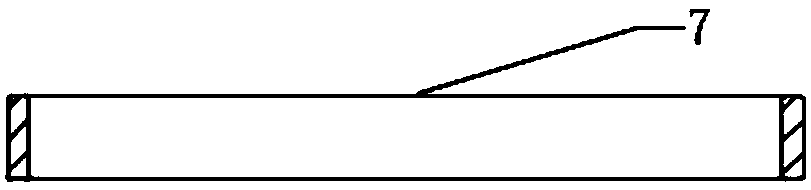

[0029] According to the embodiment of the present invention, a new sleeve-type air spring with an external restraint aluminum cover includes a sealing ring A1, a plastic upper cover 2, a pressure ring A3, a pressure ring protection cover 4, an external restraint aluminum cover 5, and a rubber airbag 6 , inner support ring 7, pressure ring B8, plastic piston 9, sealing ring B10 and gas nozzle 11, wherein, the top of rubber airbag 6 is provided with plastic upper cover 2, and the inside of plastic upper cover 2 is provided with sealing ring A1, rubber airbag 6 The top of the outer surface of the outer surface is provided with a pressure ring protection cover 4, and a pressure ring A3 is connected between the pressure ring protection cover 4 and the rubber air bag 6, and the plastic upper cover 2, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com