Magnesium alloy for building formwork and preparation method thereof

A technology of building formwork and magnesium alloy, which is applied in the field of light alloy processing, can solve the problems of non-corrosion resistance cost, poor mechanical properties, large proportion and unfavorable construction, etc., and achieve the effect of good corrosion resistance, good economic benefits, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

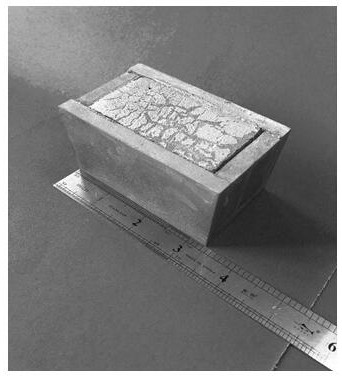

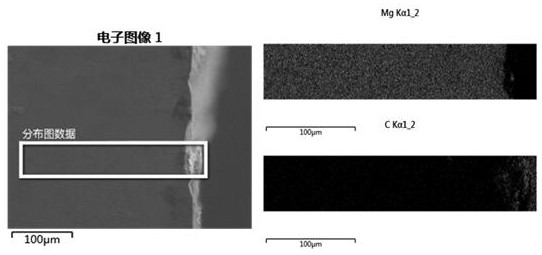

Image

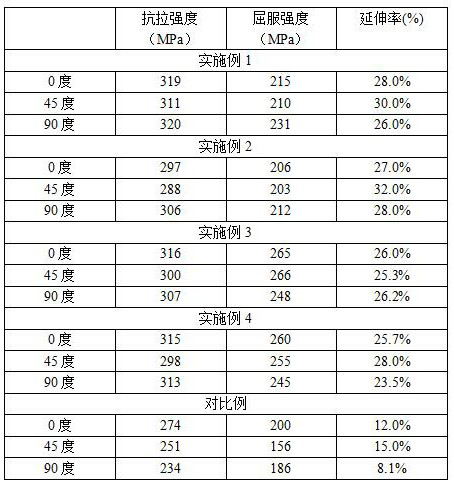

Examples

Embodiment 1

[0027] 1) Using pure magnesium ingot, pure aluminum ingot, pure zinc ingot and magnesium-manganese master alloy as raw materials, carry out mechanical grinding, according to Zn: 4.0%, Al: 0.5%, Mn: 0.5%, the balance is magnesium and inevitable impurities The mass percentage content of the ingredients is calculated;

[0028] 2) Preheat pure magnesium, pure aluminum, pure zinc and magnesium-manganese master alloy at 300℃ for 30min, then put pure magnesium ingot in resistance furnace, in SF with volume ratio of 1:99 6 and CO 2 It is completely melted under the protection of the mixed gas, and after the temperature of the magnesium melt is raised to 720 °C to stabilize, the magnesium-manganese master alloy, pure aluminum and ingot are added to the completely melted magnesium melt. When the temperature rises to 720 When the temperature is 10 min, the alloy is poured into a mold preheated to 300 °C, and the magnesium alloy ingot is obtained after cooling;

[0029] 3) machining the...

Embodiment 2

[0032] 1) Using pure magnesium ingot, pure aluminum ingot, pure zinc ingot and magnesium-manganese master alloy as raw materials, carry out mechanical grinding, according to Zn: 4.0%, Al: 0.3%, Mn: 0.3%, the balance is magnesium and inevitable impurities The mass percentage content of the ingredients is calculated;

[0033] 2) Preheat pure magnesium, pure aluminum, pure zinc and magnesium-manganese master alloy at 300℃ for 30min, then put pure magnesium ingot in resistance furnace, in SF with volume ratio of 1:99 6 and CO 2 It is completely melted under the protection of the mixed gas, and after the temperature of the magnesium melt is raised to 720 °C to stabilize, the magnesium-manganese master alloy, pure aluminum and ingot are added to the completely melted magnesium melt. When the temperature rises to 720 When the temperature is 10 min, the alloy is poured into a mold preheated to 300 °C, and the magnesium alloy ingot is obtained after cooling;

[0034] 3) machining the...

Embodiment 3

[0037] 1) Use pure magnesium ingots, pure strontium, pure zinc ingots and magnesium-manganese master alloys as raw materials for mechanical grinding, according to Zn: 2.0%, Sr: 0.3%, Mn: 1.5%, and the balance is magnesium and unavoidable impurities. The mass percentage is used to calculate the ingredients.

[0038] 2) Preheat pure magnesium, pure strontium, pure zinc and magnesium-manganese master alloy at 300°C for 30 minutes, then place the pure magnesium ingot in a resistance furnace, in the SF with a volume ratio of 1:99 6 and CO 2 Under the protection of the mixed gas, it is completely melted, and the temperature of the magnesium melt is raised to 720°C. At ~740°C, after holding for 10 minutes, pour the alloy into a mold preheated to 300°C, and obtain a magnesium alloy ingot after cooling;

[0039] 3) Machining the magnesium alloy ingot obtained in step 2) to a specified size to obtain a magnesium alloy profile;

[0040] 4) Use an extrusion die to hot-extrude the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com