Unfreezing method used for unfreezing device

A radio frequency and generation module technology, applied in the field of thawing, can solve the problems of food quality loss, uneven thawing, uneven distribution of the internal material of food, etc., to prevent excessive thawing, improve thawing efficiency, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

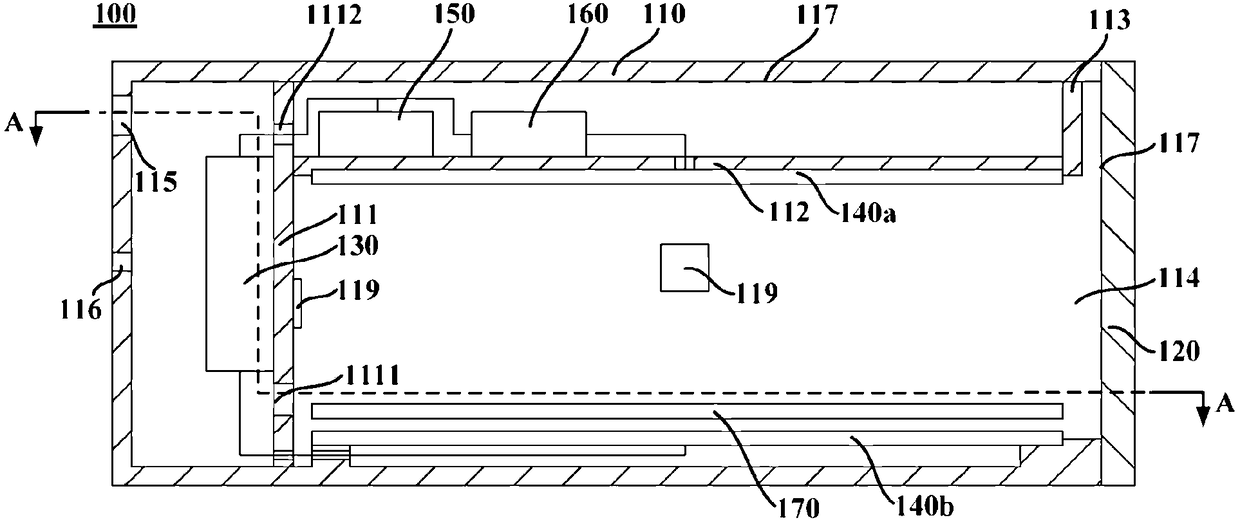

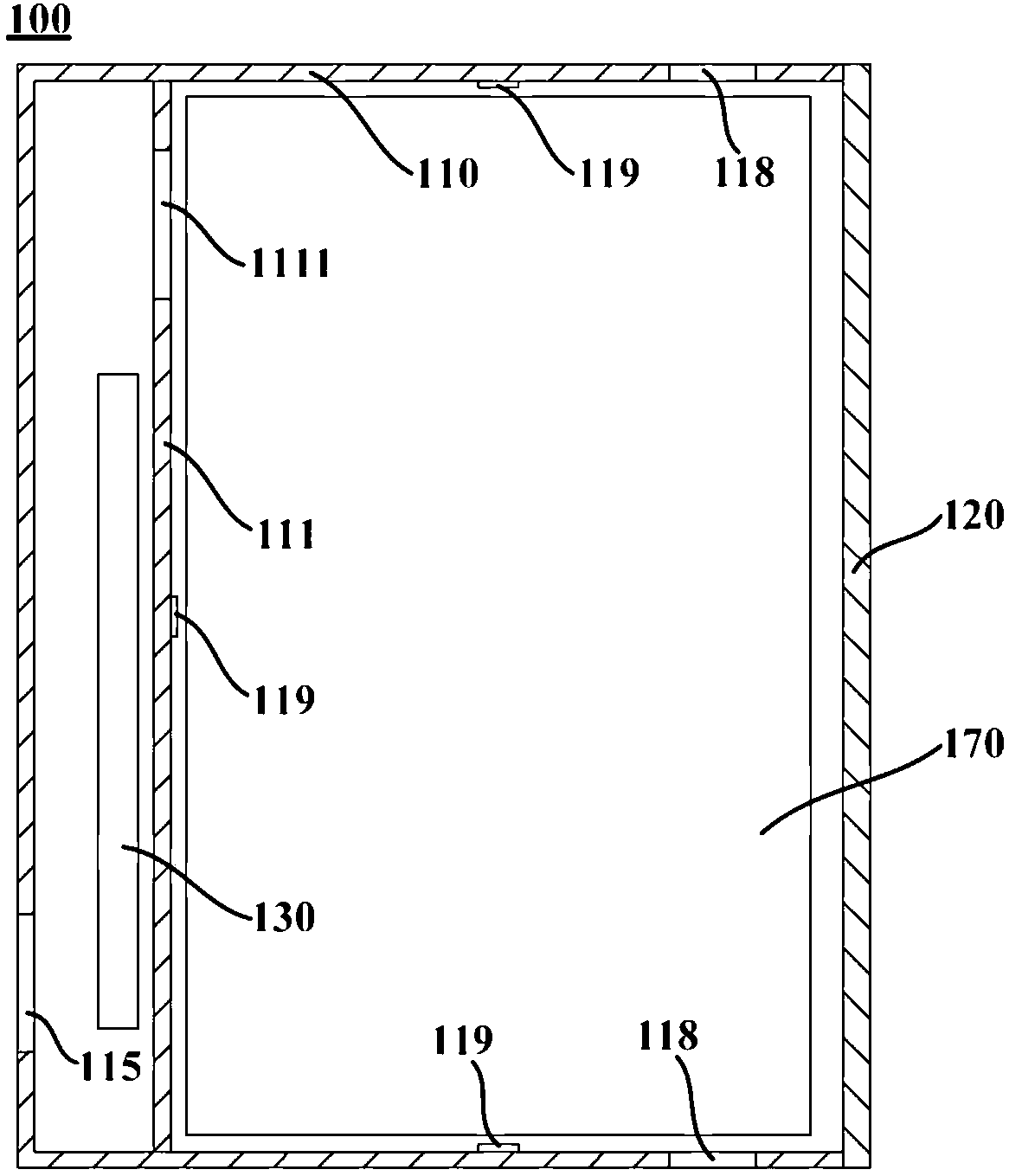

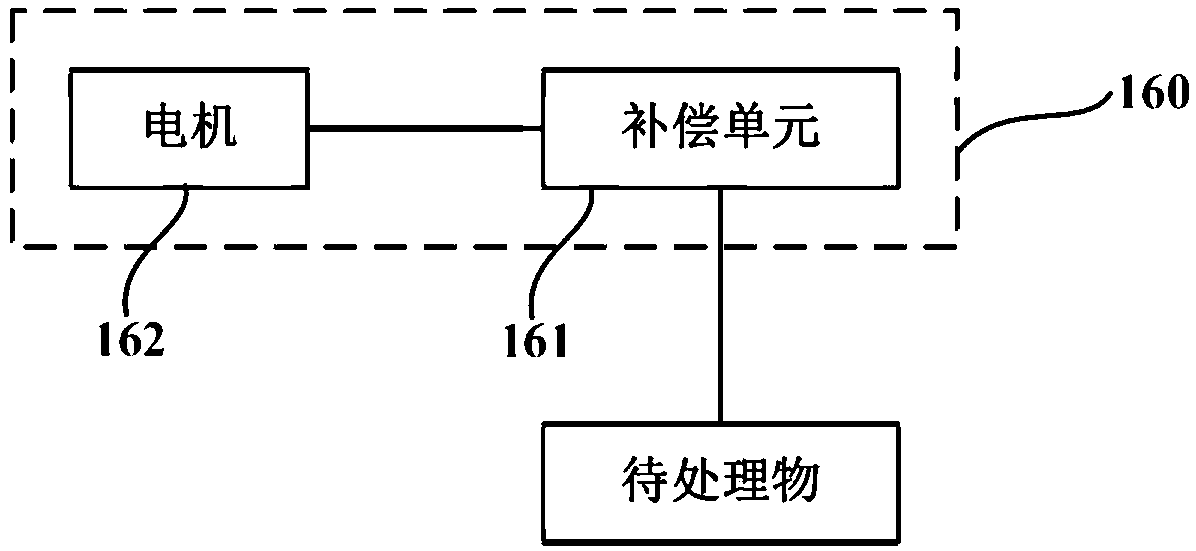

[0061] figure 1 is a schematic structural diagram of a thawing device 100 according to an embodiment of the present invention. see figure 1 The thawing device 100 may include a cylinder body 110, a device door 120, a radio frequency generating module 130, and an upper electrode plate 140a and a lower electrode plate 140b. The cylinder body 110 may include a top plate, a bottom plate, a rear plate and two opposite lateral side plates, and a thawing chamber 114 with a front opening may be defined therein, and the thawing chamber 114 is used for placing objects to be processed. The device door 120 can be disposed at the front opening of the thawing chamber 114 for opening or closing the thawing chamber 114 . The device door 120 can be installed together with the cylinder body 110 by an appropriate method, such as a left-handed door, a right-handed door, an upper-handed door or a sliding door. The radio frequency generating module 130 can be configured to generate radio frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com