Novel ore pulp concentration meter based on ELM network and measurement method

A measurement method and a concentration meter technology, applied in the field of measurement, can solve problems such as the inability to realize automatic control of pulp concentration, hidden dangers of radioactive source environment and safety, and influence on the accuracy of measurement results, so as to reduce system complexity, long maintenance period, Measuring Rapid Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

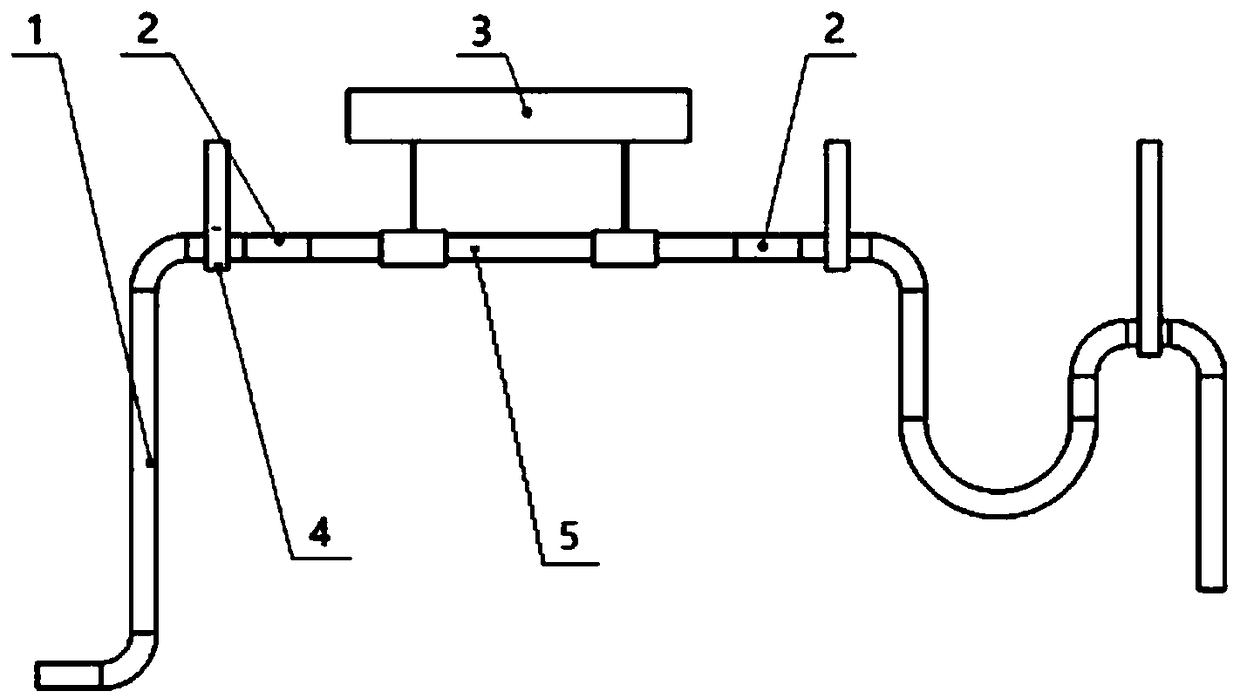

[0040] like figure 1 and figure 2 As shown, the measuring tube 5 is fixed on the measuring end of the electronic scale 3 , and the two ends of the measuring tube 5 are respectively connected to the guide pipe 1 and the drain pipe through the hose 2 . The water inlet of the diversion pipe 1 is low, the slurry flows from the left to the right in the figure, and the water inlet of the diversion pipe 1 faces the slurry flow. The drain outlet of the drain pipe is higher than the horizontal position of the water inlet, and can be located close to the liquid level of the slurry flow, and the direction of the drain outlet is perpendicular to or away from the flow direction of the slurry. A slurry pump can be provided at the diversion pipe 1, which can speed up the flow rate of the ore slurry in the entire drainage pipeline. When the slurry concentration changes, the slurry in the entire measuring tube 5 can be renewed more quickly.

[0041] The drain also includes a section of inv...

Embodiment 2

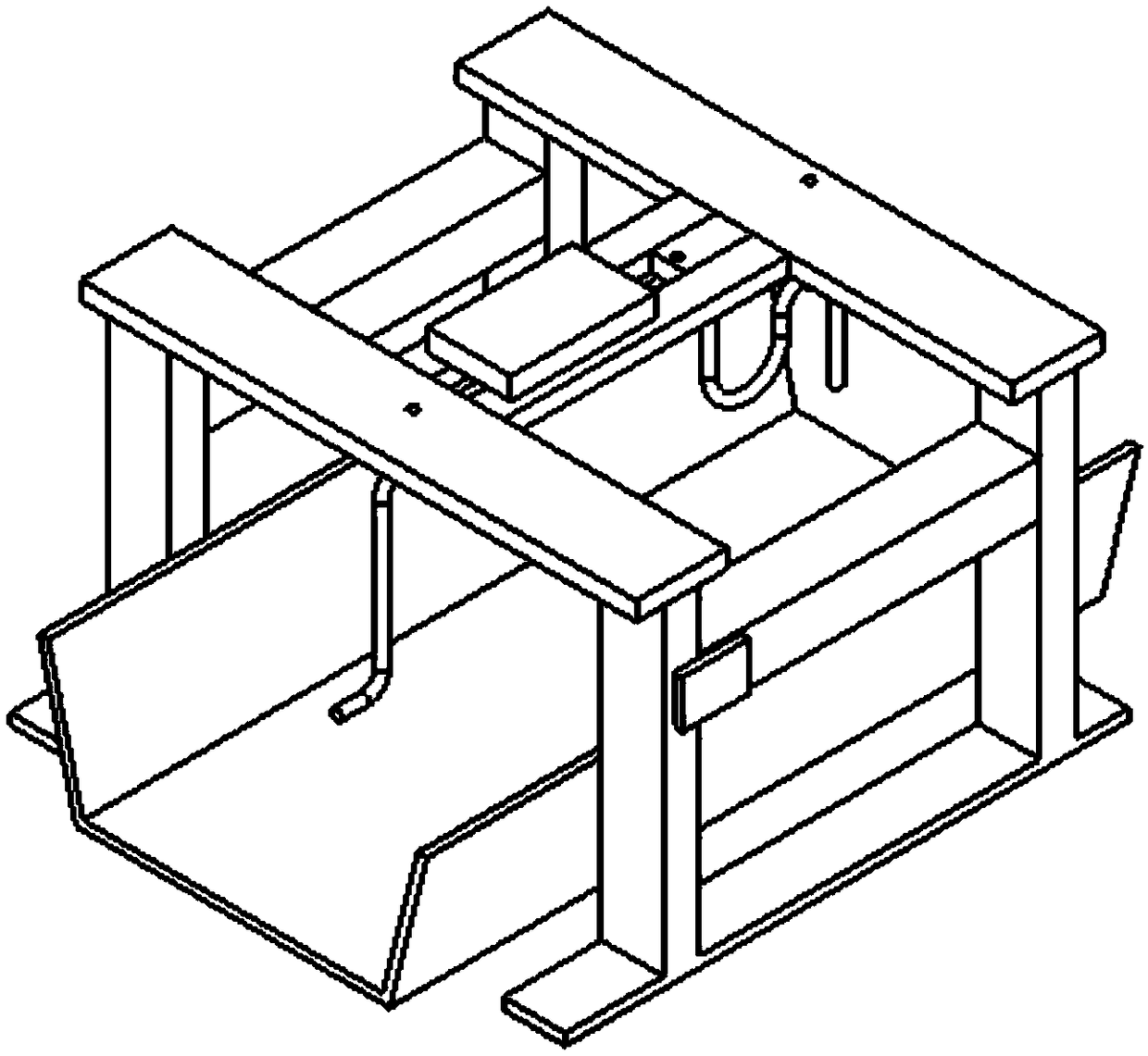

[0048] The diversion pipe 1 and the drainage pipe of the drainage pipeline in this embodiment respectively lead into the slurry flow from the side wall of the slurry tank. The entire drainage pipeline is below the liquid level of the slurry. Seal the connection. This embodiment is a fixed concentration meter.

[0049] The body of the electronic scale 3 is fixed, and the measuring tube 5 and the measuring end of the electronic scale 3 can move up and down. The measurement zero point can be preset when there is no liquid in the measuring tube 5, the weight signal obtained by the electronic weighing device 3 is the pulp weight, and the pulp weight signal, namely the analog signal M, is transmitted to the signal processing terminal. The length of the measuring tube 5 is 1m, and the diameter of the inner hole is 0.0333m. The pulp concentration ρ is calculated by ρ=M / V.

Embodiment 3

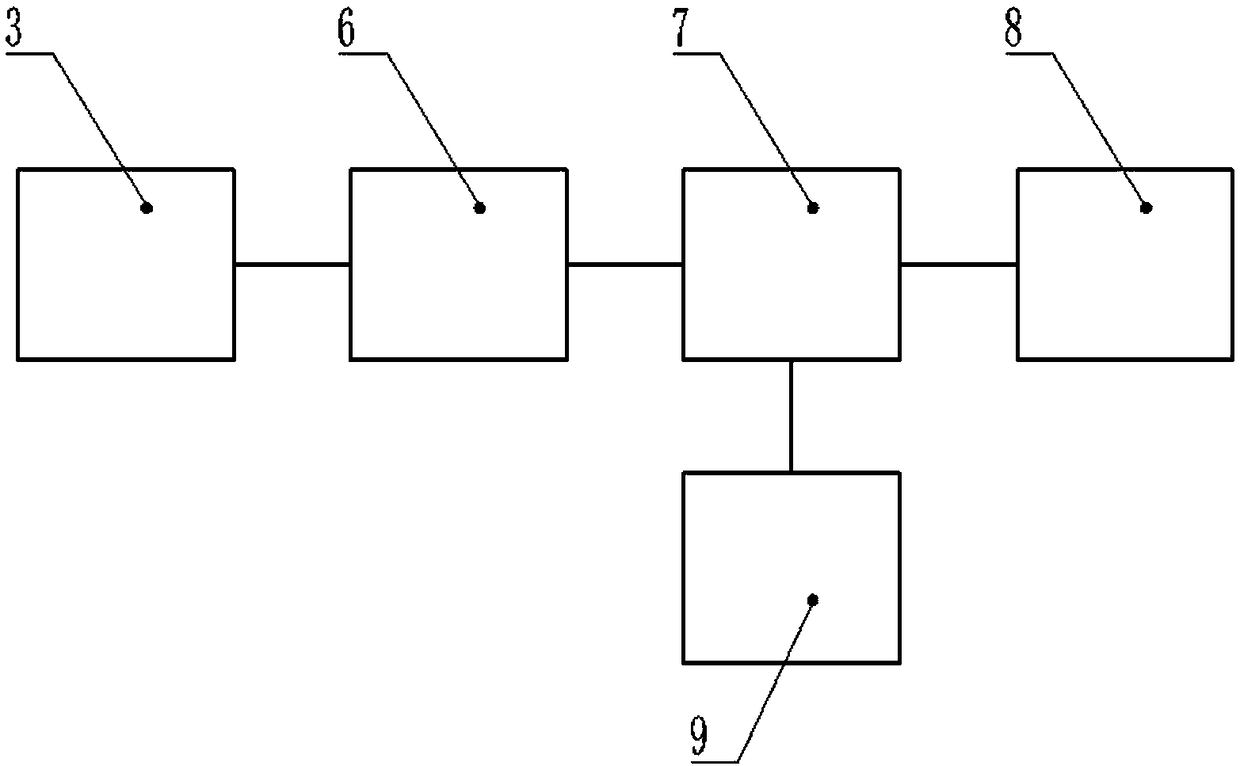

[0051] Weigh the weight of the liquid in the measuring tube (5) to obtain the analog signal M;

[0052] Convert the analog signal M into a digital signal M';

[0053] Divide the obtained continuous 5 digital signals M' into a group, remove a maximum value and a minimum value in each group, and calculate the arithmetic mean of the remaining 3 digital signals M', that is, a filtered signal M" is obtained;

[0054] The ore concentration ρ is obtained by ELM neural network calculation on the continuous filtered digital signal M″ arranged along the time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com