Semiconductor production remote monitoring system based on OCR image processing technology

A remote monitoring system and image processing technology, applied in electrical program control, comprehensive factory control, etc., can solve problems such as unsupported, increased production costs, and reduced automated production levels, saving R&D and testing costs, and long R&D cycles. , the effect of resolving limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

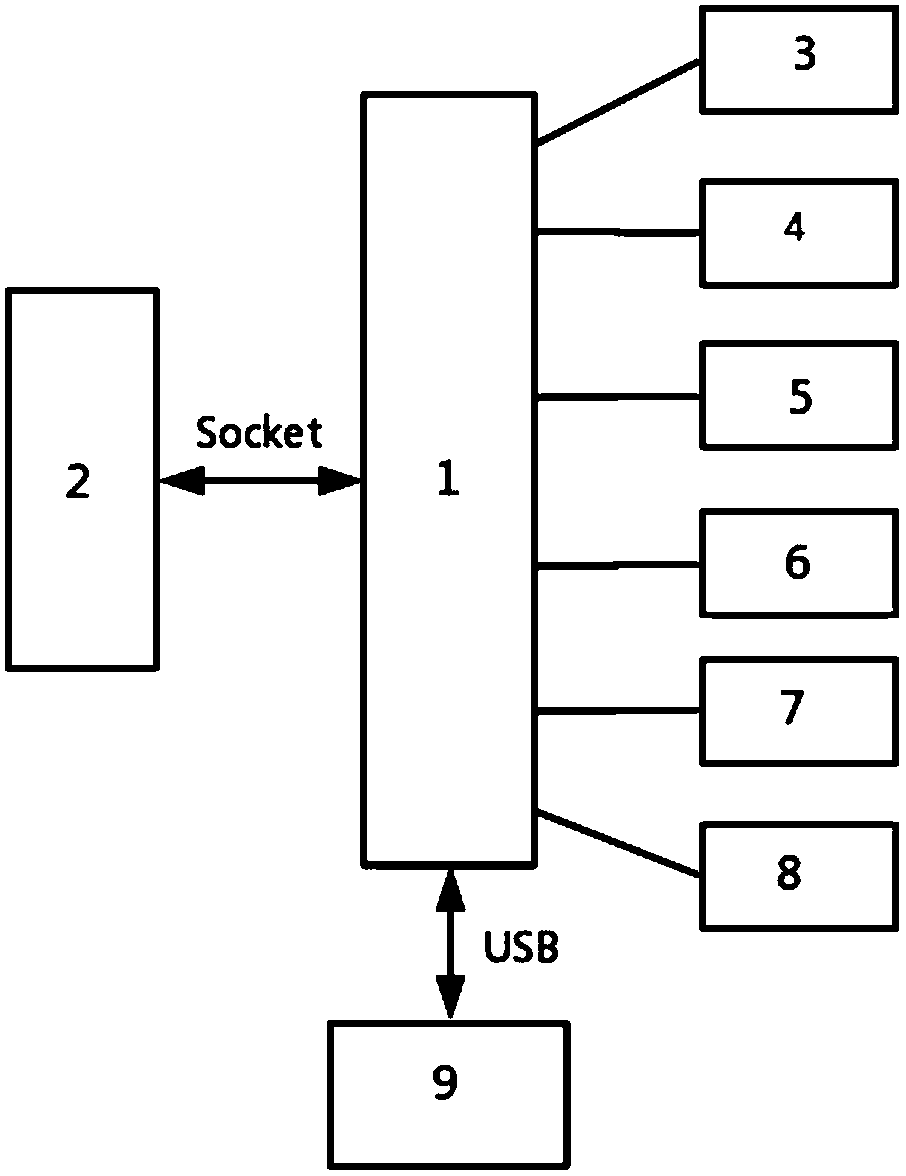

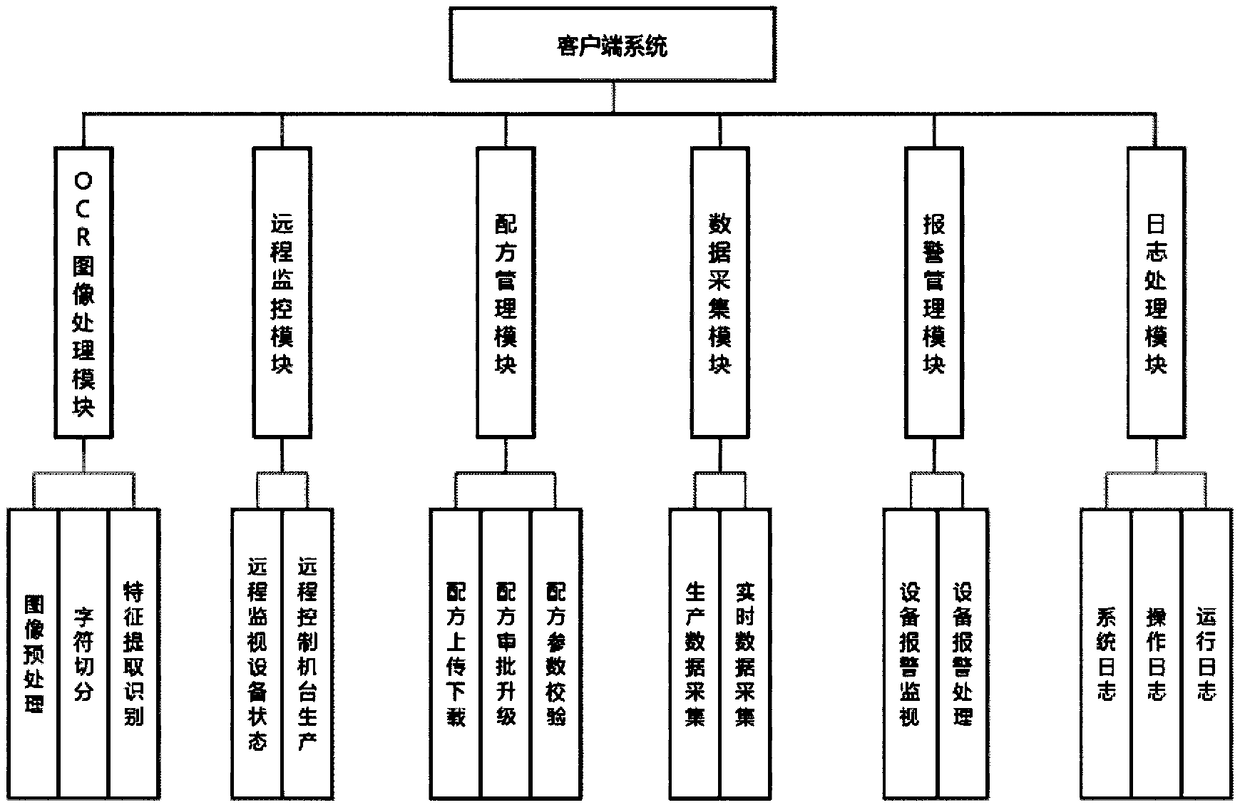

[0020] Such as figure 1 As shown, a semiconductor production remote monitoring system based on OCR image processing technology of the present invention includes a client system 1 and a central control server 2. The client system 1 interacts with machine equipment 9 through a USB interface to read the machine The device 9 parameters and sends instructions to control the action of the machine device 9. The central control server 2 is connected to the client system 1 through a Socket programming interface based on the TCP / IP protocol to control the operation of the client system 1 . The transport layer protocol in the TCP / IP protocol family mainly includes TCP and UDP. The main difference between the TCP protocol and the UDP protocol is that the TCP protocol can ensure that the data can reach the other end and has high reliability, while the UDP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com