A high-precision sub-pixel circular part measuring method

A technology of round parts and measurement methods, which is applied in the directions of measuring devices, image enhancement, image analysis, etc., can solve the problems of easy fatigue, high strength, high cost, etc., and achieve the effects of avoiding easy fatigue, enhancing robustness, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

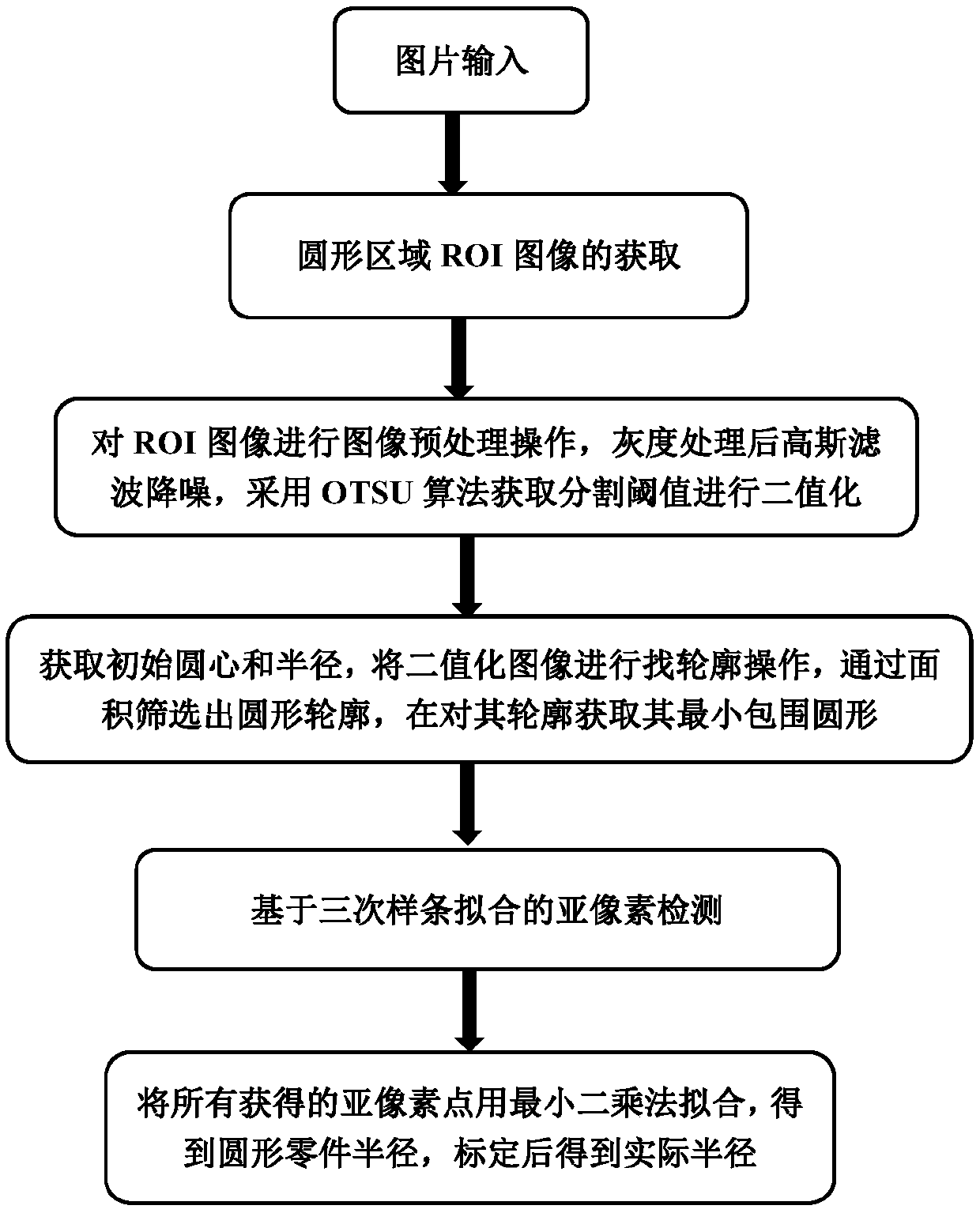

[0037] Such as Figure 1~6 As shown, a high-precision sub-pixel circular part measurement method includes the following steps:

[0038] Step 1, obtain the original image of the circular part, such as figure 2 shown;

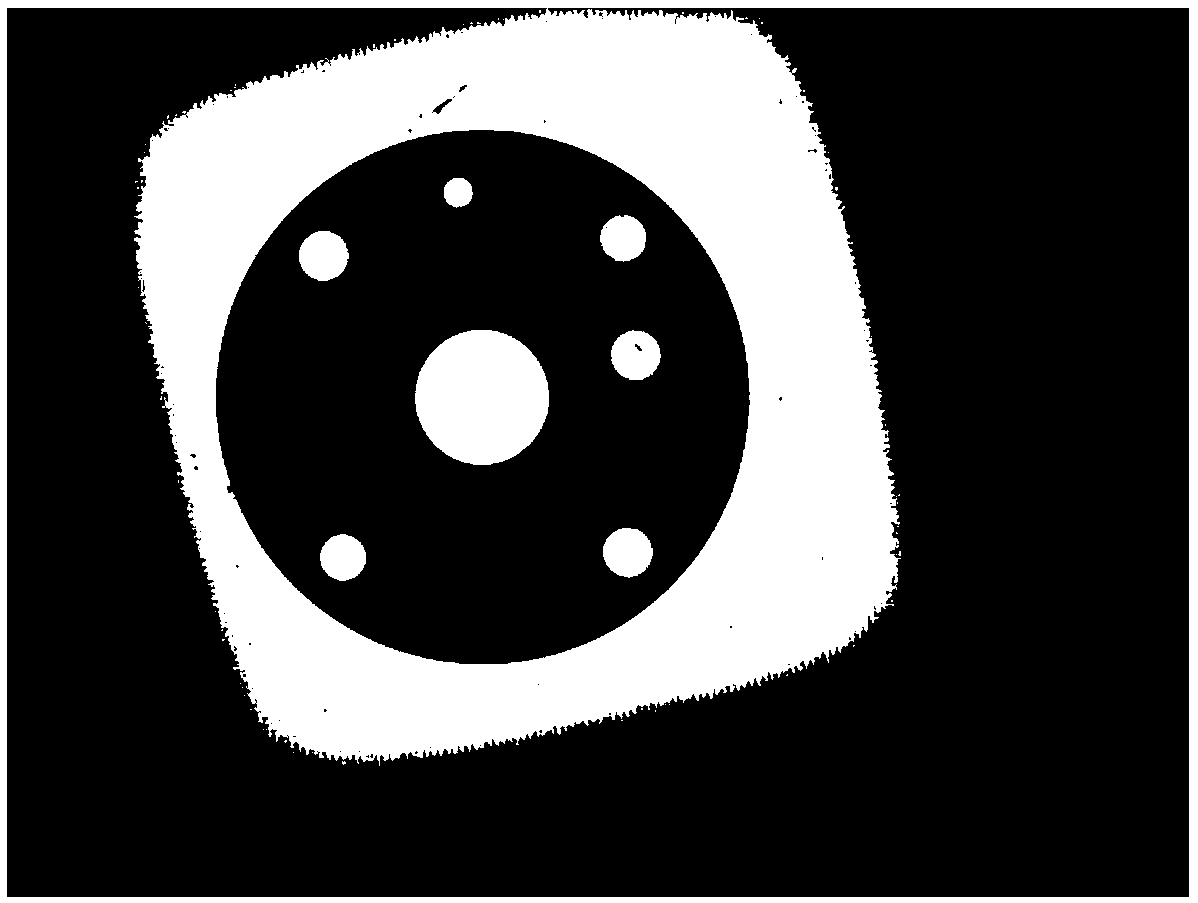

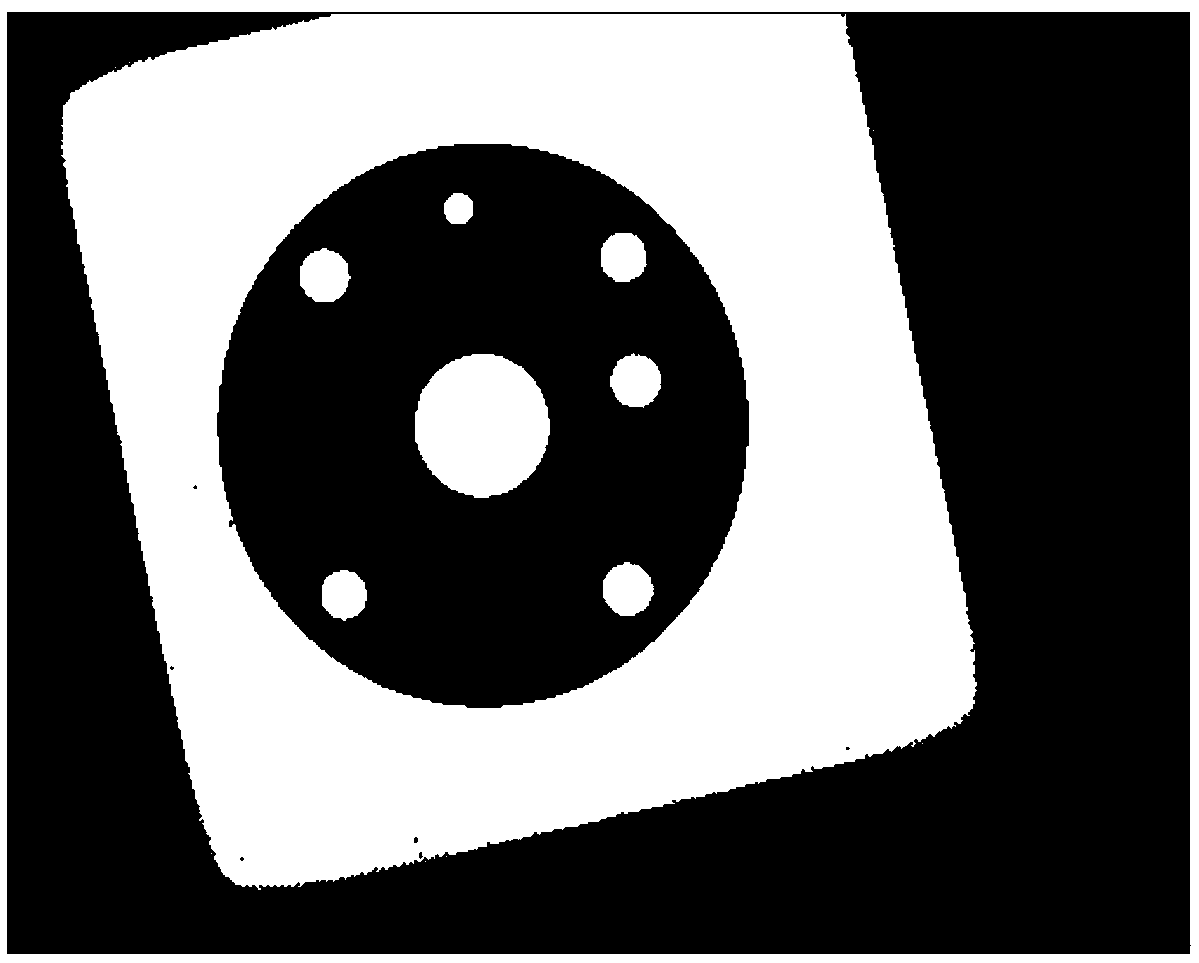

[0039] Step 2, binarize the original image obtained in step 1, such as image 3 As shown, and then use the findContours algorithm to find the contour of the binarized image, and then filter out the circular contour that meets the measurement needs by setting the maximum and minimum values of the contour area, and then obtain the maximum value of the circular contour The lower circumscribed rectangle, so as to obtain the ROI image of the area where the circle to be measured is located, such as Figure 4 As shown, this operation can reduce the image, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com