Device and method for treating mussels before eating

A processing device and technology for mussels, applied in application, food science, slaughtering and other directions, can solve the problems of poor processing effect, high labor intensity, low processing efficiency, etc., and achieve low work efficiency, high labor intensity and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

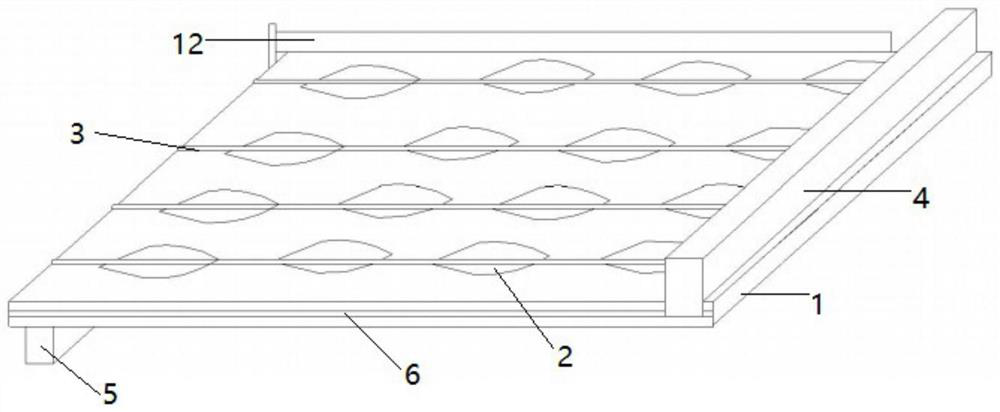

[0031] like figure 1 The illustrated embodiment is a mussel processing device before eating, comprising a rectangular substrate 1, 4 rows of mussel limiting holes 2 arranged on the substrate to match the shape of the mussels, and a hole 2 arranged on the upper surface of the substrate. 4 mussel pressure rods 3, 2 support rods passing through the lower part of each row of mussel limiting holes, the upper brush 4 for scrubbing the upper shell of the mussels and the brush 4 for scrubbing the mussels on the base plate The lower brush 5 of the lower housing; the front side and the rear side of the substrate are respectively provided with a front guide rail 6 and a rear guide rail, and the upper brush and the lower brush are respectively slidably connected with the front guide rail and the rear guide rail; The diversion chamber, the upper brush is provided with drain holes, the diversion chamber is connected with the water inlet pipe, and the water inlet pipe is provided with a sole...

Embodiment 2

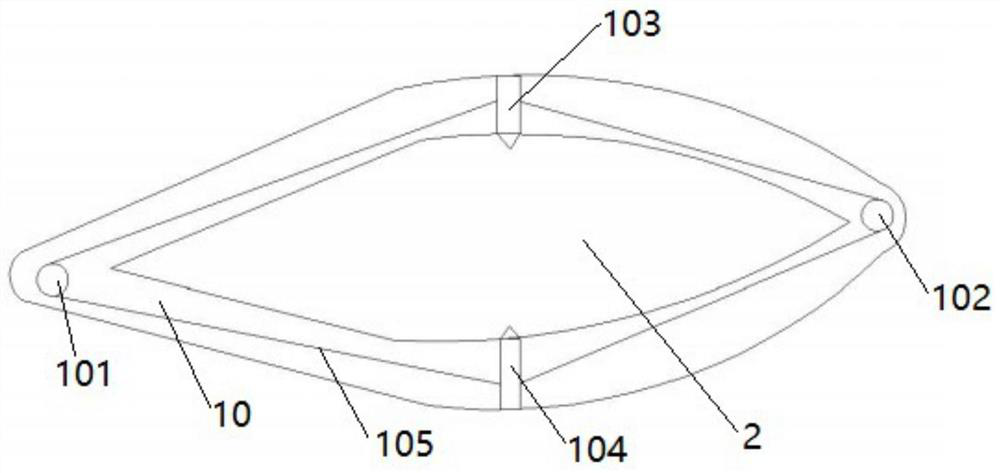

[0041] Embodiment 2 includes all structure and method parts of embodiment 1, such as figure 2 As shown, in embodiment 2, a guide channel 10 surrounding the mussel limit hole is provided in the base plate close to each mussel limit hole, and a left retractor 101, a right retractor 102, a first The cutter 103 and the second cutter 104; the left retractor and the right retractor are respectively connected with the first cutter and the second cutter through the rope 105, and the first cutter and the second cutter pass through several The slide block is slidably connected to the opposite side wall of the guide channel; the cutter heads 96 at the front of the first cutter and the second cutter all protrude from the opening on the side wall of the guide channel and contact with the edge of the mussel shell;

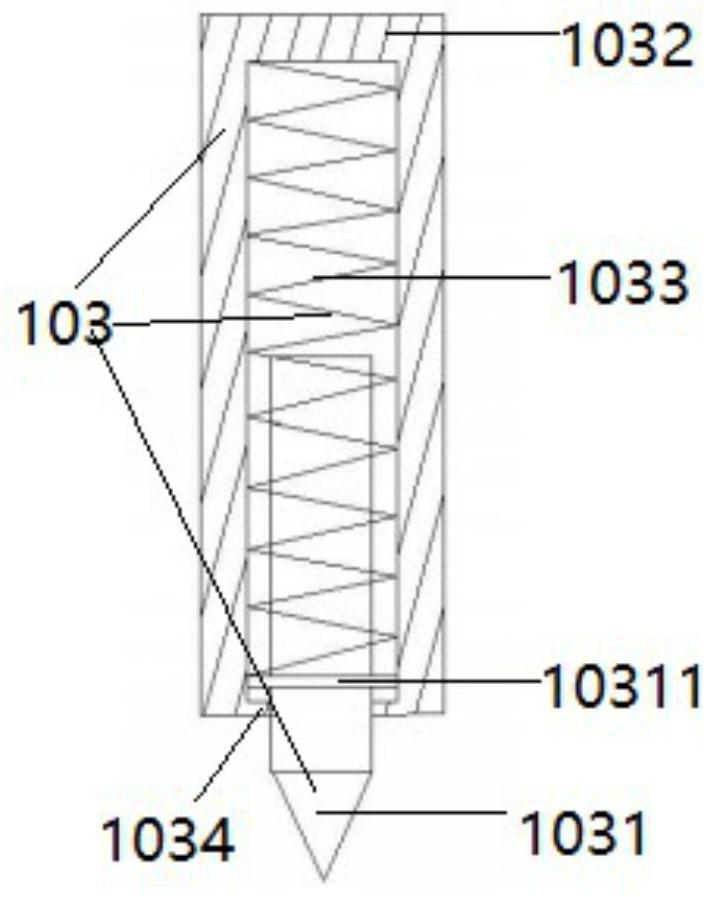

[0042]like image 3 As shown, the first cutting knife includes a guide cylinder 1032 and a spring 1033 located in the guide cylinder. The upper part of the cutter head extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com