Pressing type bean pulp smashing device

A crushing device and compacting device technology, which is applied in the direction of grain processing, etc., can solve the problems of soybean meal sticking on the crushing plate body, affecting work, affecting the quality and work efficiency of soybean meal crushing, etc., achieving ingenious structural design, reasonable structure, Effects that add mass and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

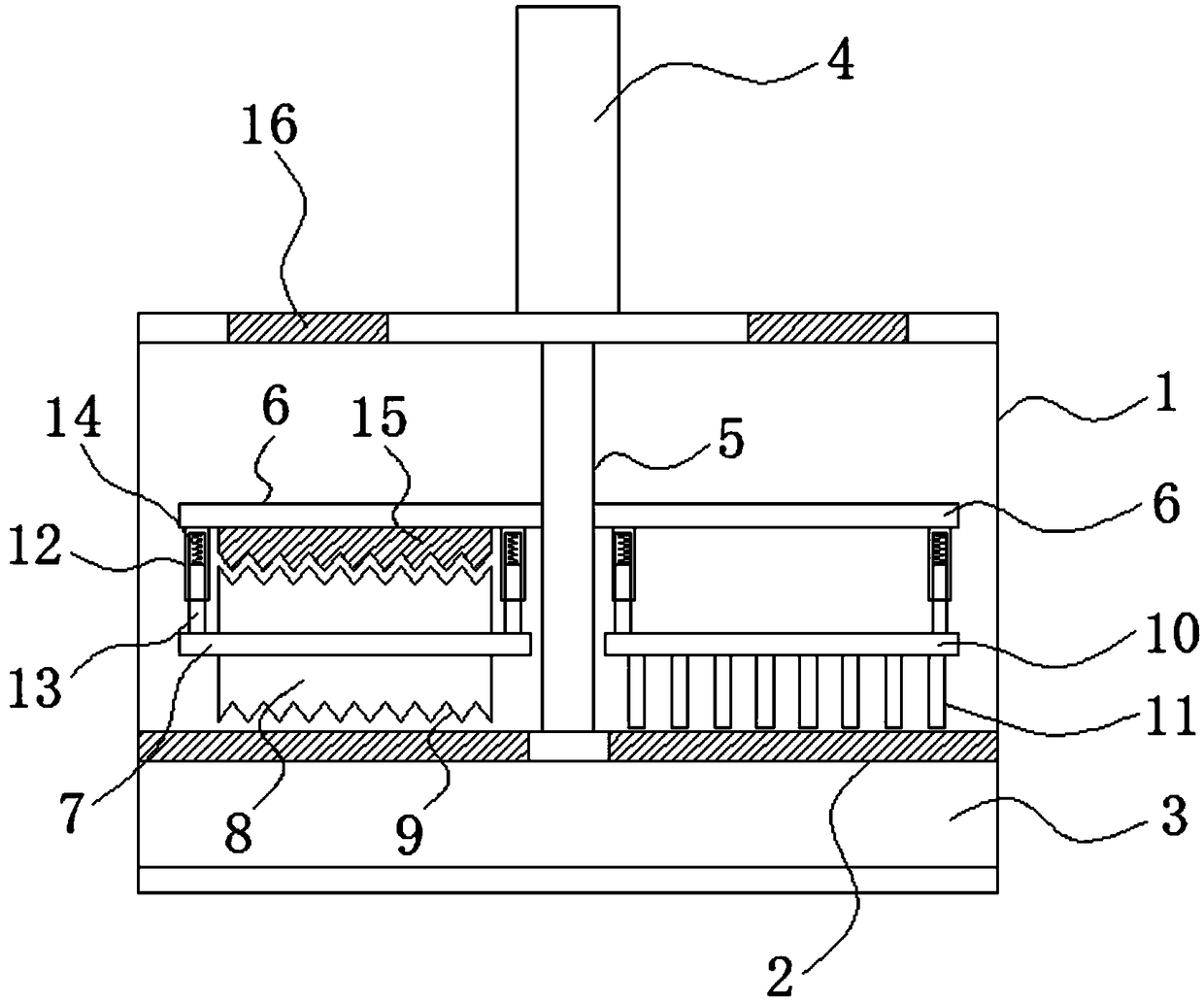

[0012] Such as figure 1 As shown, a compacting soybean meal crushing device includes a crushing box 1; a screen 2 is installed in the crushing box 1; the lower area of the screen 2 is set as a bin 3; and the middle position of the screen 2 is also set There is a bearing seat; a crushing motor 4 is also installed above the crushing box 1; the motor rod of the crushing motor 4 is equipped with a main shaft 5, and the main shaft 5 extends into the box from the top of the crushing box 1 and is installed on the sieve On the bearing seat 3 of the net 2; and the square bar 6 protruding later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com