A construction spraying device

A technology for spraying device and construction, applied in the direction of spraying device, liquid spraying device, etc., can solve problems such as affecting work efficiency, and achieve the effect of improving conveying accuracy, improving performance and reducing mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The construction spraying device is further described with reference to the accompanying drawings.

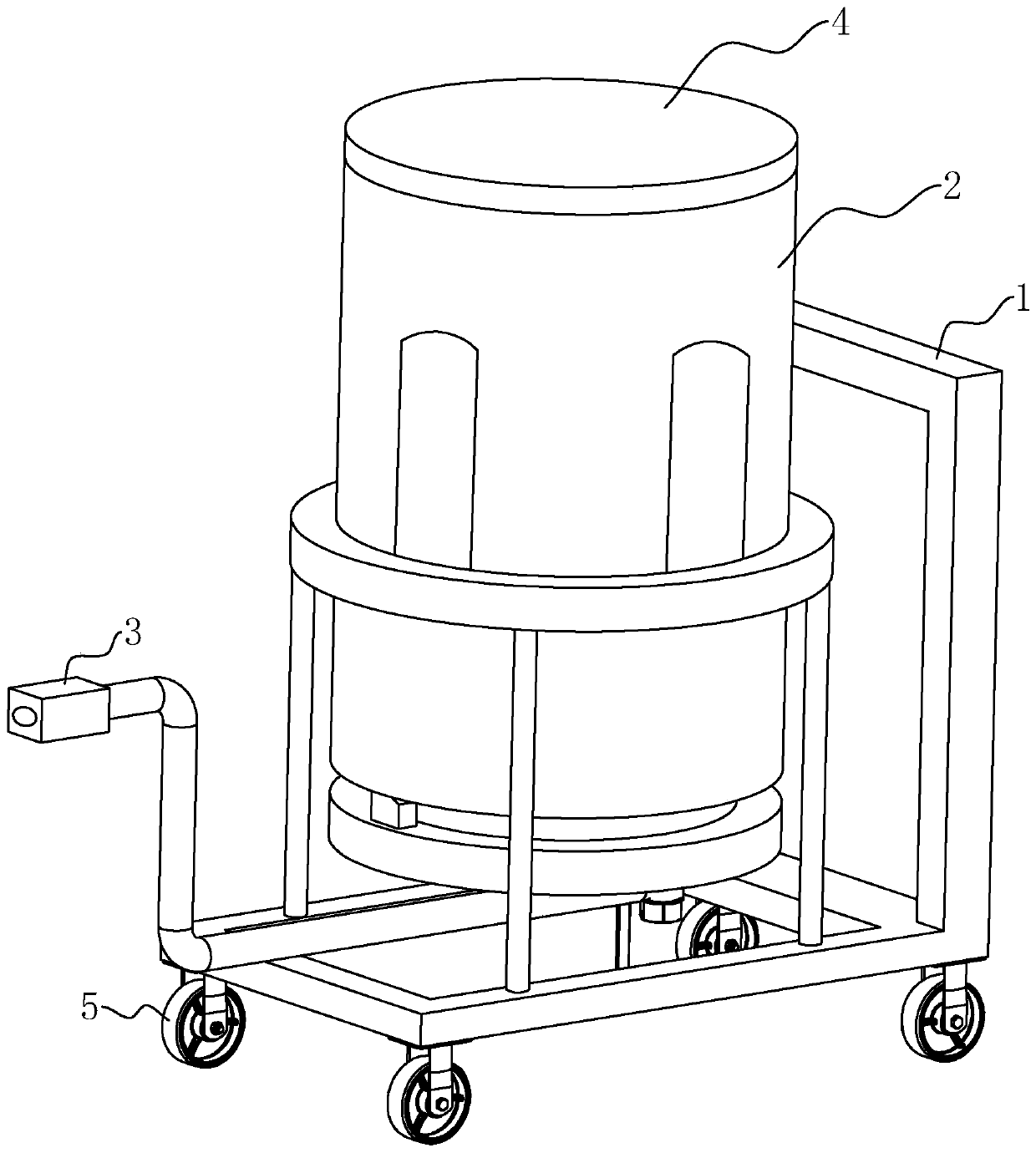

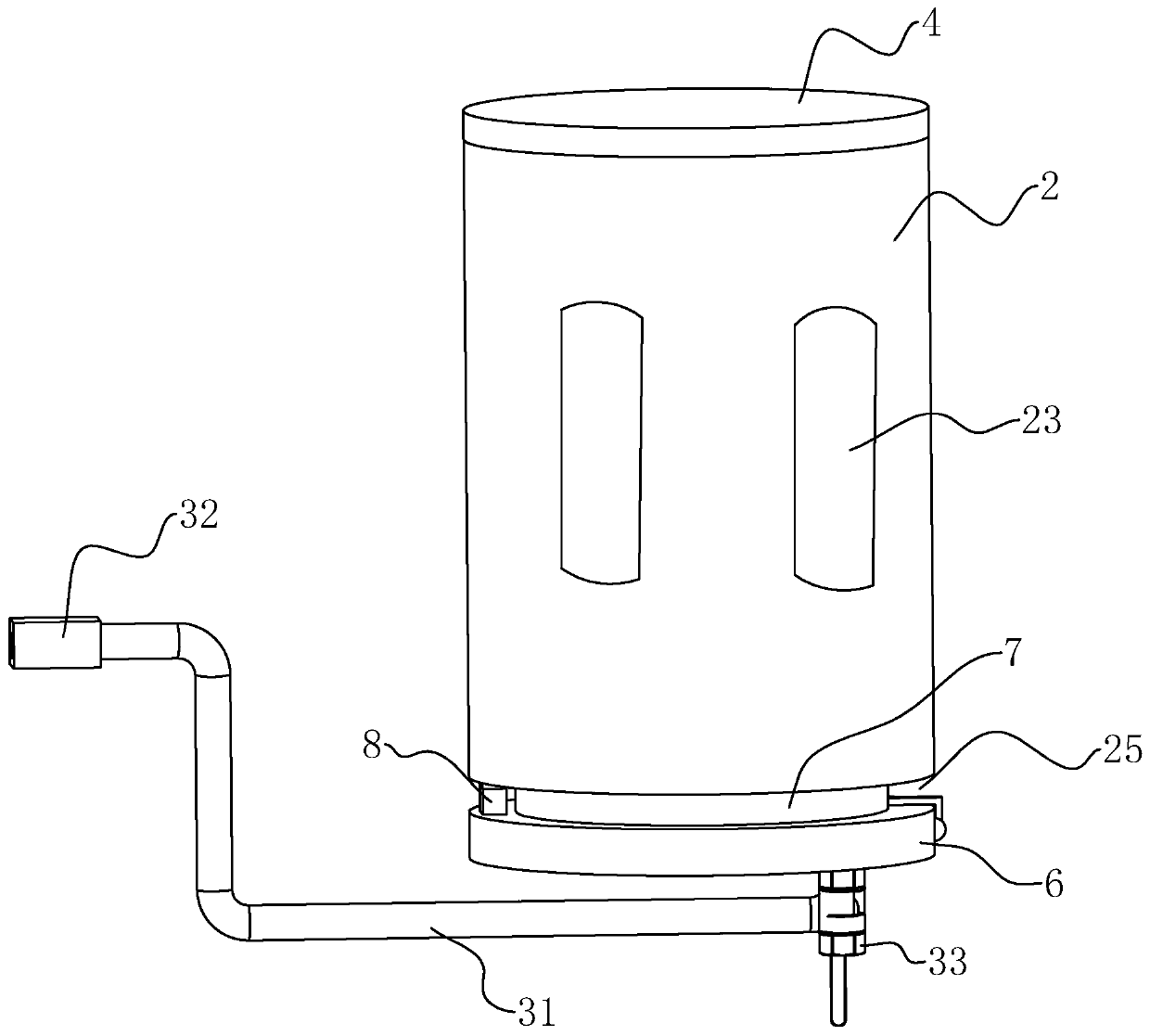

[0039] A construction spraying device, such as figure 1 As shown, it includes a support frame 1, a barrel 2 arranged on the support frame 1 for containing materials, a spray assembly 3 connected to the barrel 2 for spraying paint, an end cap 4 covering the opening of the barrel 2 and The guide wheels 5 arranged at the bottom of the support frame 1 are used to drive the support frame 1 to move.

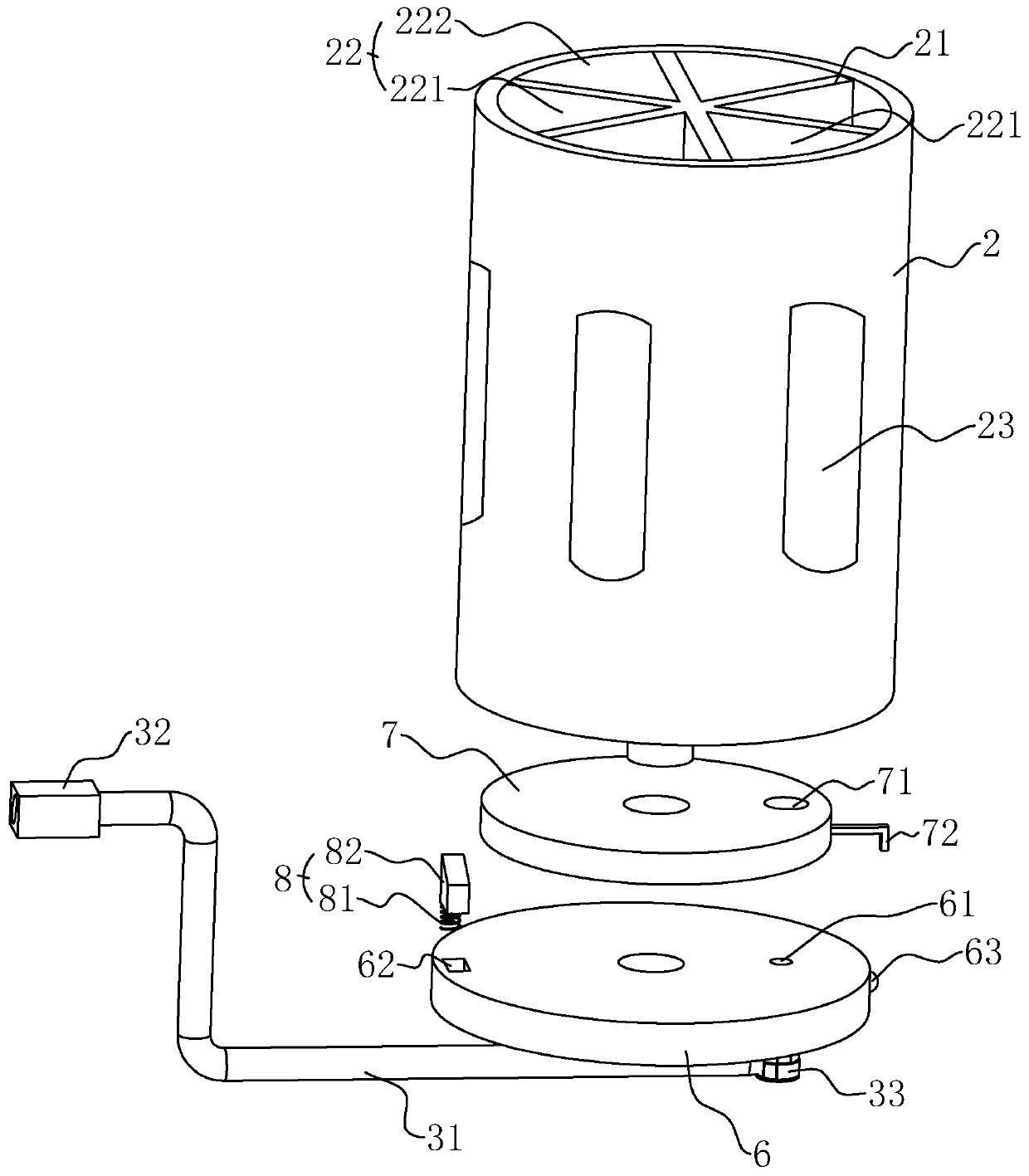

[0040] combine figure 2 and image 3 As shown, wherein, a plurality of longitudinal partitions 21 are arranged in the barrel 2, and one end of the plurality of longitudinal partitions 21 converges on the axis of the barrel 2, and the other ends are fixedly connected to the inner wall of the barrel 2, And the barrel 2 is separated into several independent charging units 22 for holding materials; One or more; this solution is set to five coating units 221 and one cleaning unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com