Aluminum alloy sectional material surface detecting and split charging mechanism

An aluminum alloy profile, surface detection technology, applied in sorting and other directions, can solve the problems of lower detection accuracy of surface detectors, poor product sorting accuracy, and insufficient detection accuracy, and achieve convenient product grasping, improve work efficiency, The effect of reducing labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0020] Example.

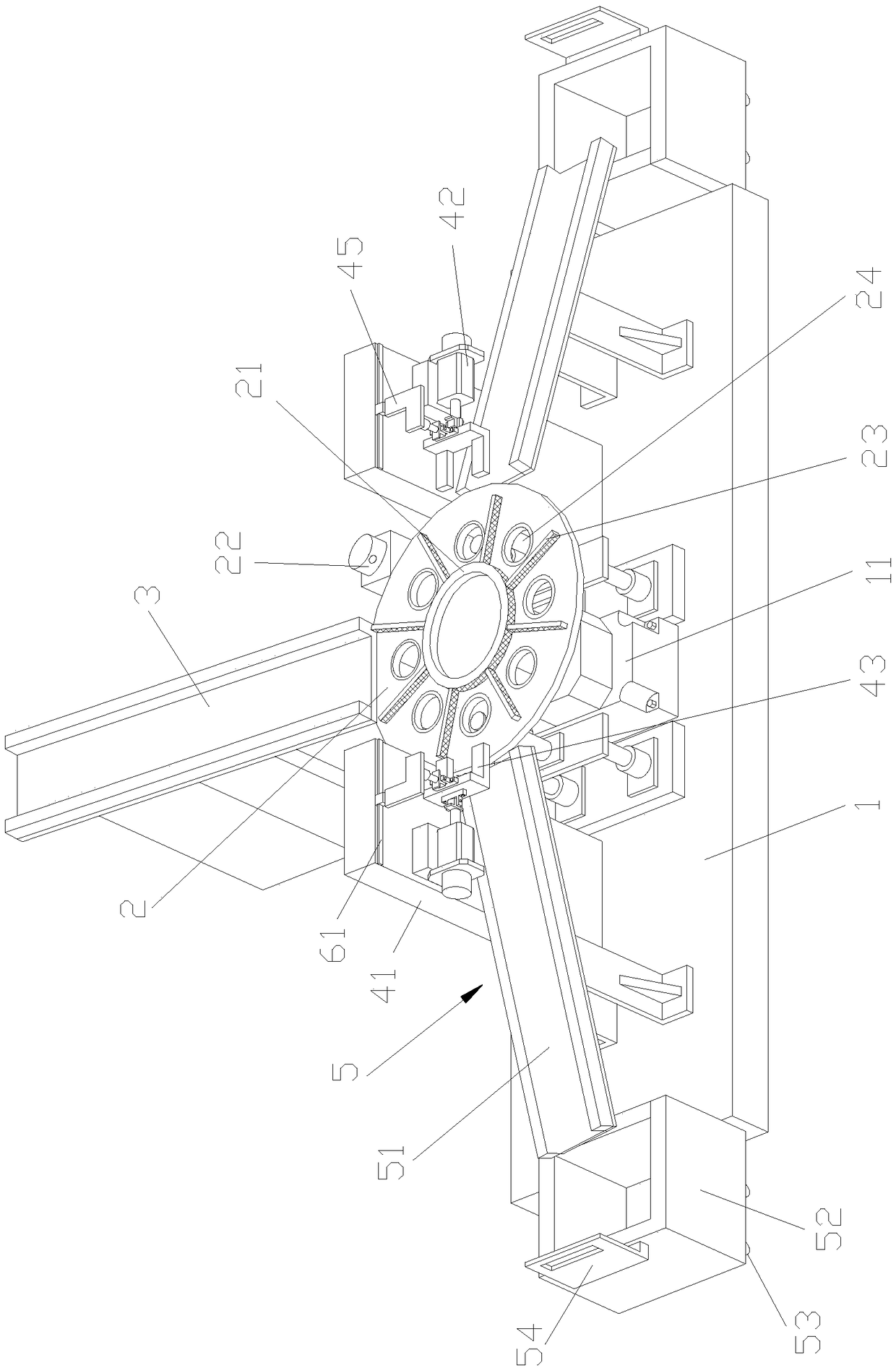

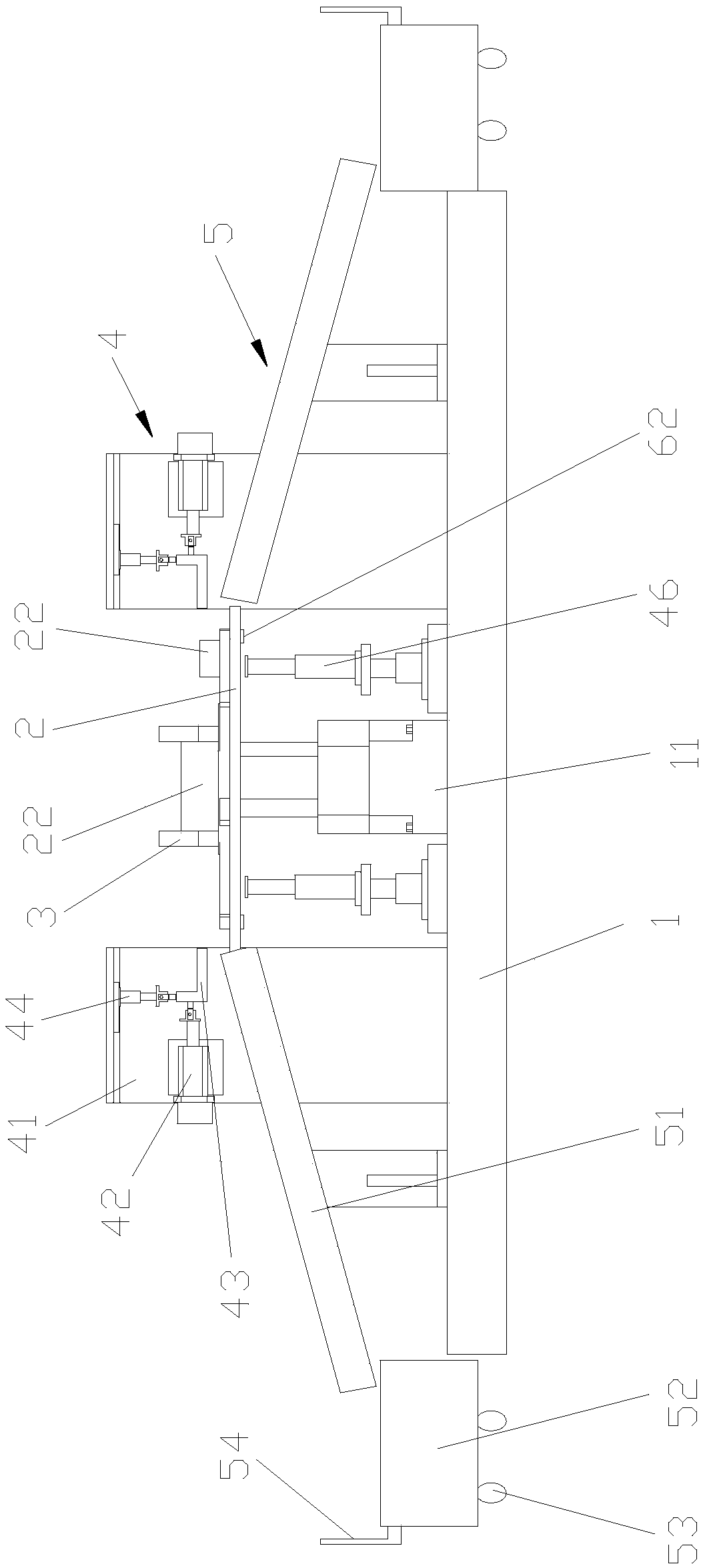

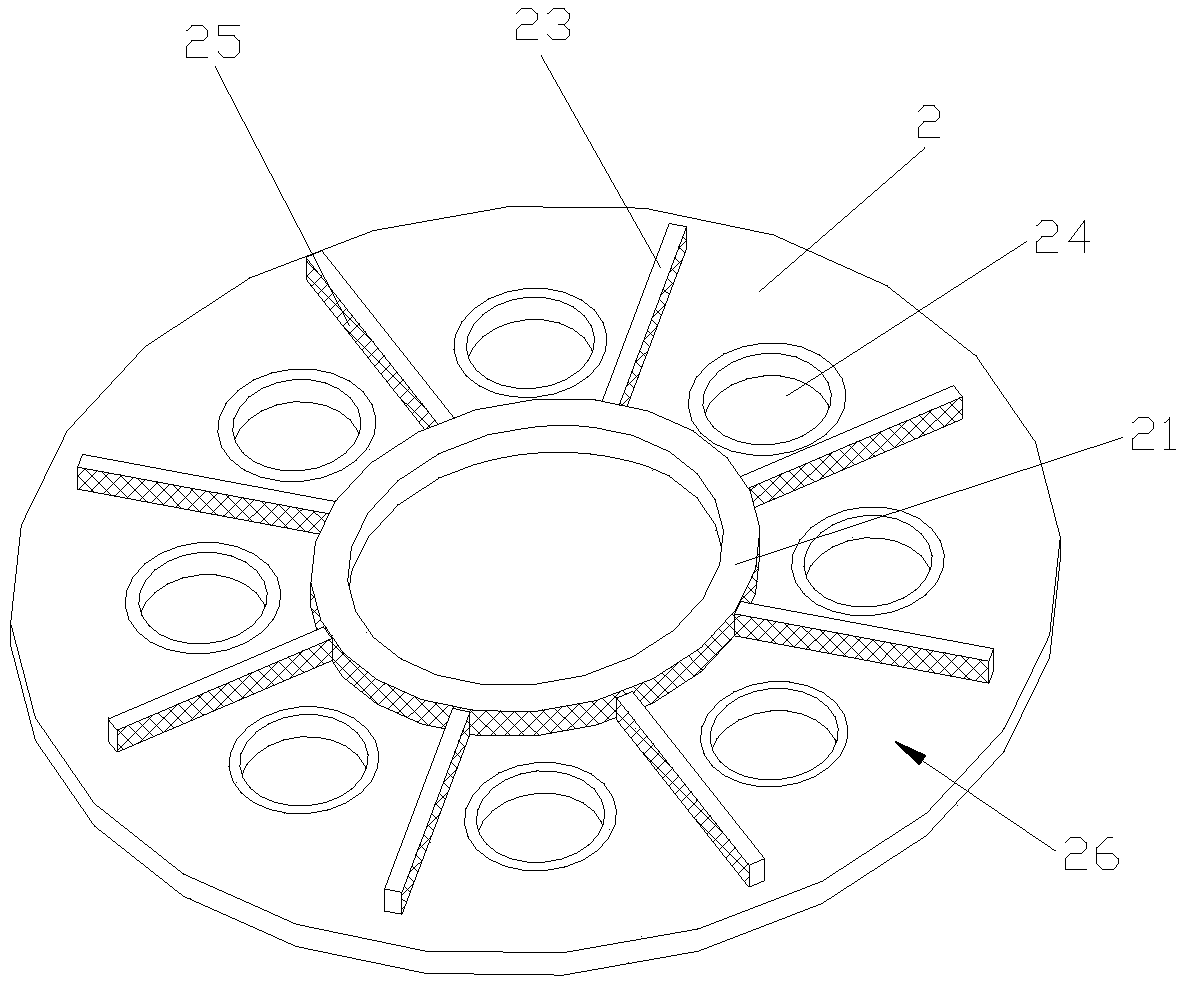

[0021] Such as figure 1 and image 3 As shown, a surface detection and packaging mechanism for aluminum alloy profiles includes a workbench 1, a rotating motor 11 is arranged on the workbench 1, a diverter plate 2 is arranged on the rotating shaft of the rotating motor 11, and the diverter plate 2 is provided with a spacer ring 21 at the center of the surface, and the outer ring surface of the spacer ring 21 is evenly provided with spacer bars 23 distributed radially, and a placement area 26 is formed between adjacent spacer bars 23. A through hole 24 is provided; a feed plate 3 and a surface detector 22 are provided on the outside of the splitter plate 2, the feed plate 3 is arranged obliquely, the lower end of the feed plate 3 faces the splitter plate 2, and the side of the splitter plate 2 A pair of axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com