Automated plate material stamping device

A sheet metal stamping and sheet metal technology is applied in the field of automatic sheet metal stamping devices, which can solve the problems of unfavorable stamping machine processing, inconvenient installation, complex structure, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

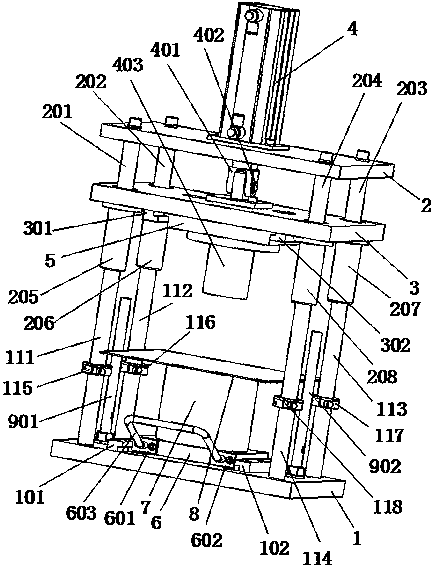

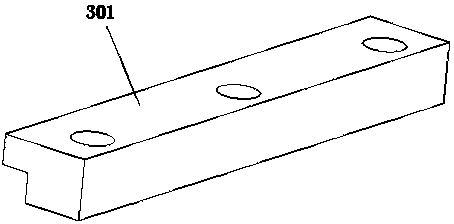

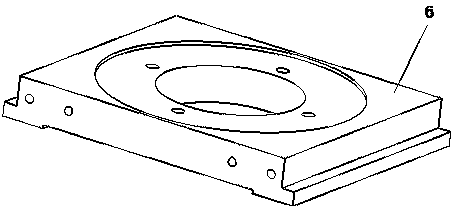

[0022] Such as Figure 1-Figure 3 As shown, the described automatic sheet metal stamping device includes a stamping base 1, a stamping top plate 2, and a stamping adjustment plate 3, the stamping adjustment plate 3 is located above the stamping base 1, and the stamping top plate 2 is located on the Above the stamping adjustment plate 3; a punch 4 is installed in the middle of the stamping top plate 2, and a first upper L-shaped slide seat 301 and a second upper L-shaped sliding seat 301 are detachably installed at the lower end of the stamping adjustment plate 3. slide seat 302, and a top support seat 5 is installed between the first upper L-shaped slide seat 301 and the second upper L-shaped slide seat 302, and an ear seat 401 is installed at the bottom end of the stamping rod of the punch 4 , a stamping column 403 is installed in the lug 401 through a tightener 402, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap