Shaft tube chamfering device for transmission shaft machining

A technology of chamfering device and drive shaft, which is applied in metal processing and other directions, can solve the problems of low loading and unloading efficiency, affecting the efficiency of shaft tube processing, and low chamfering efficiency, and achieves the effect of facilitating assembly and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

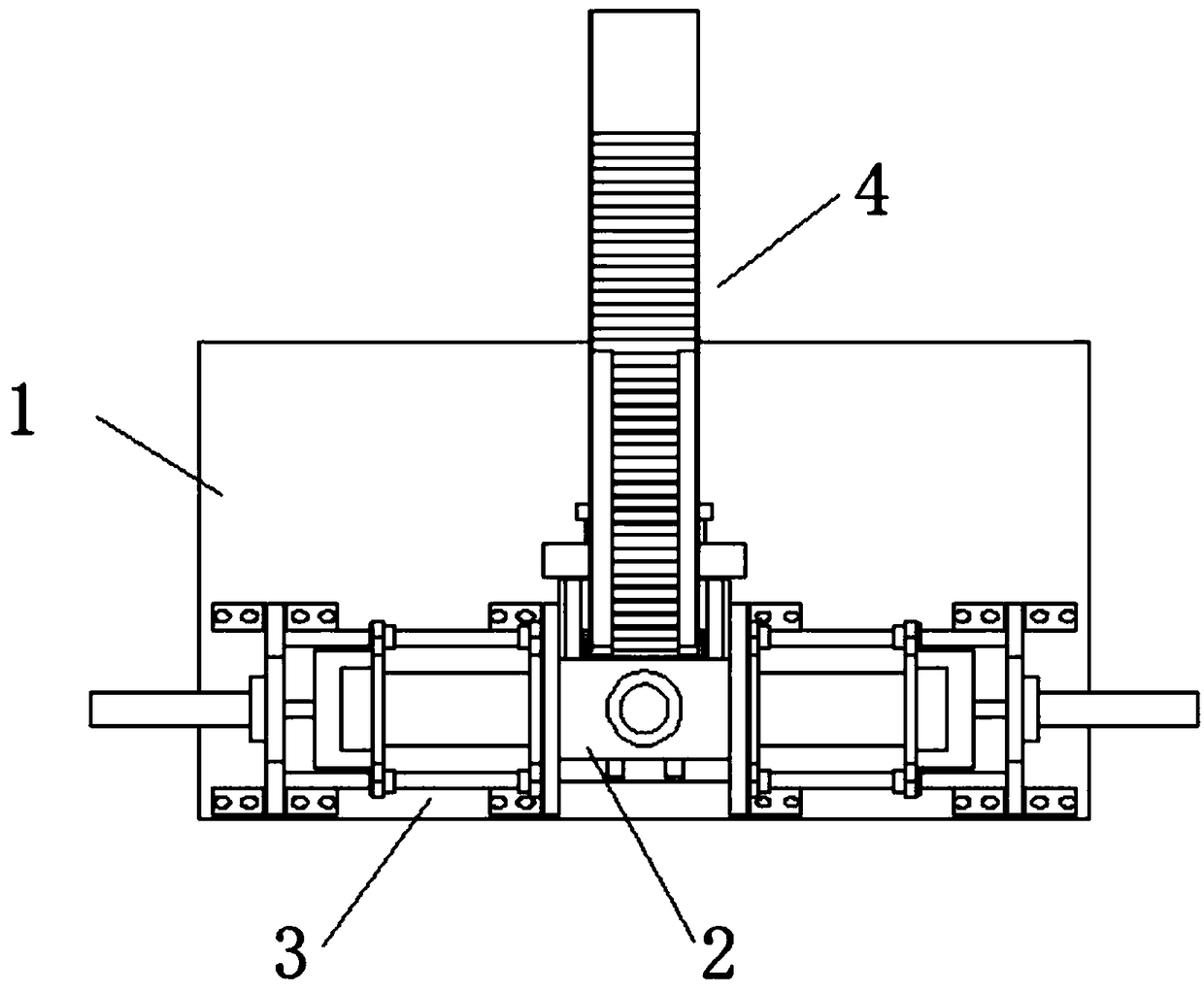

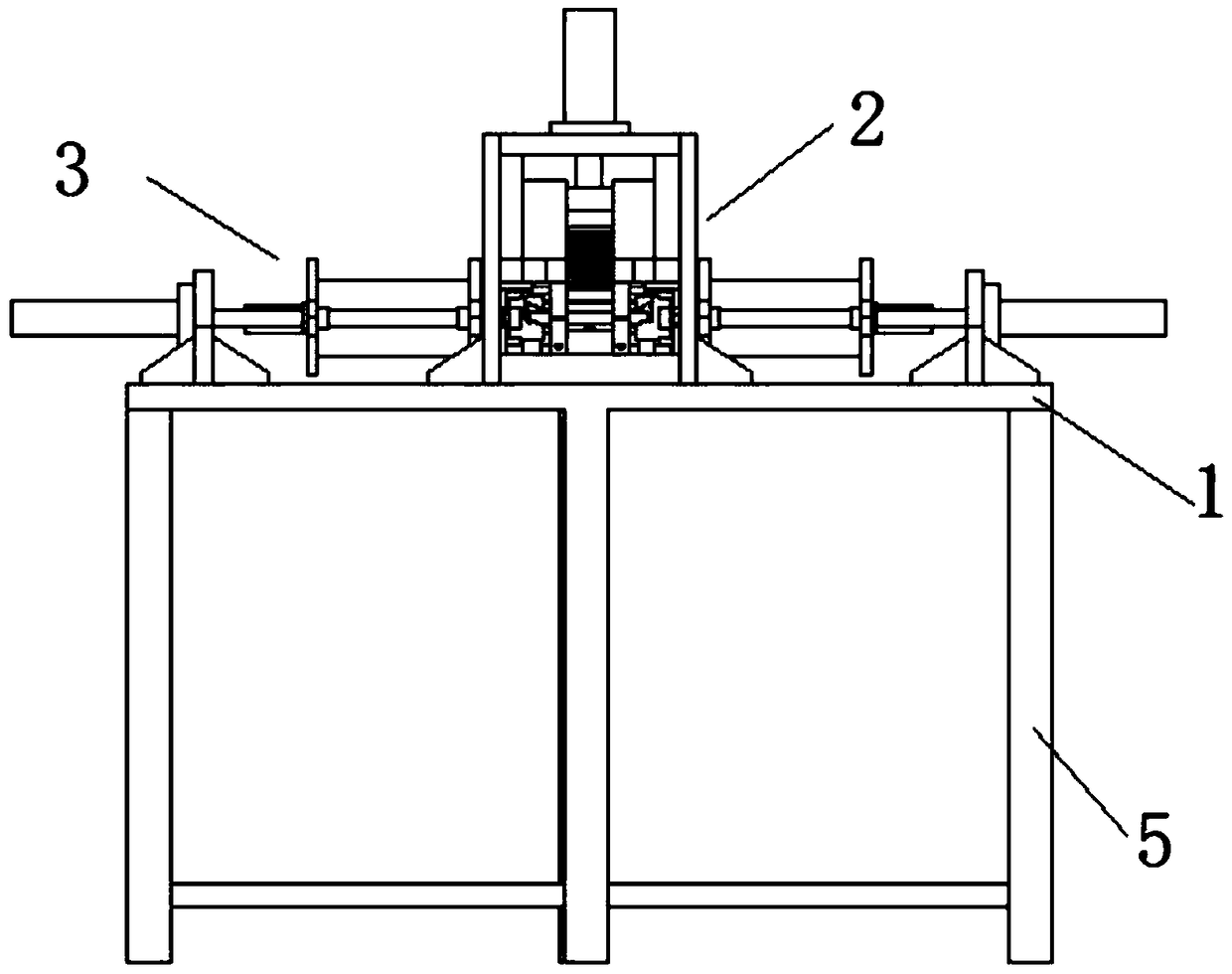

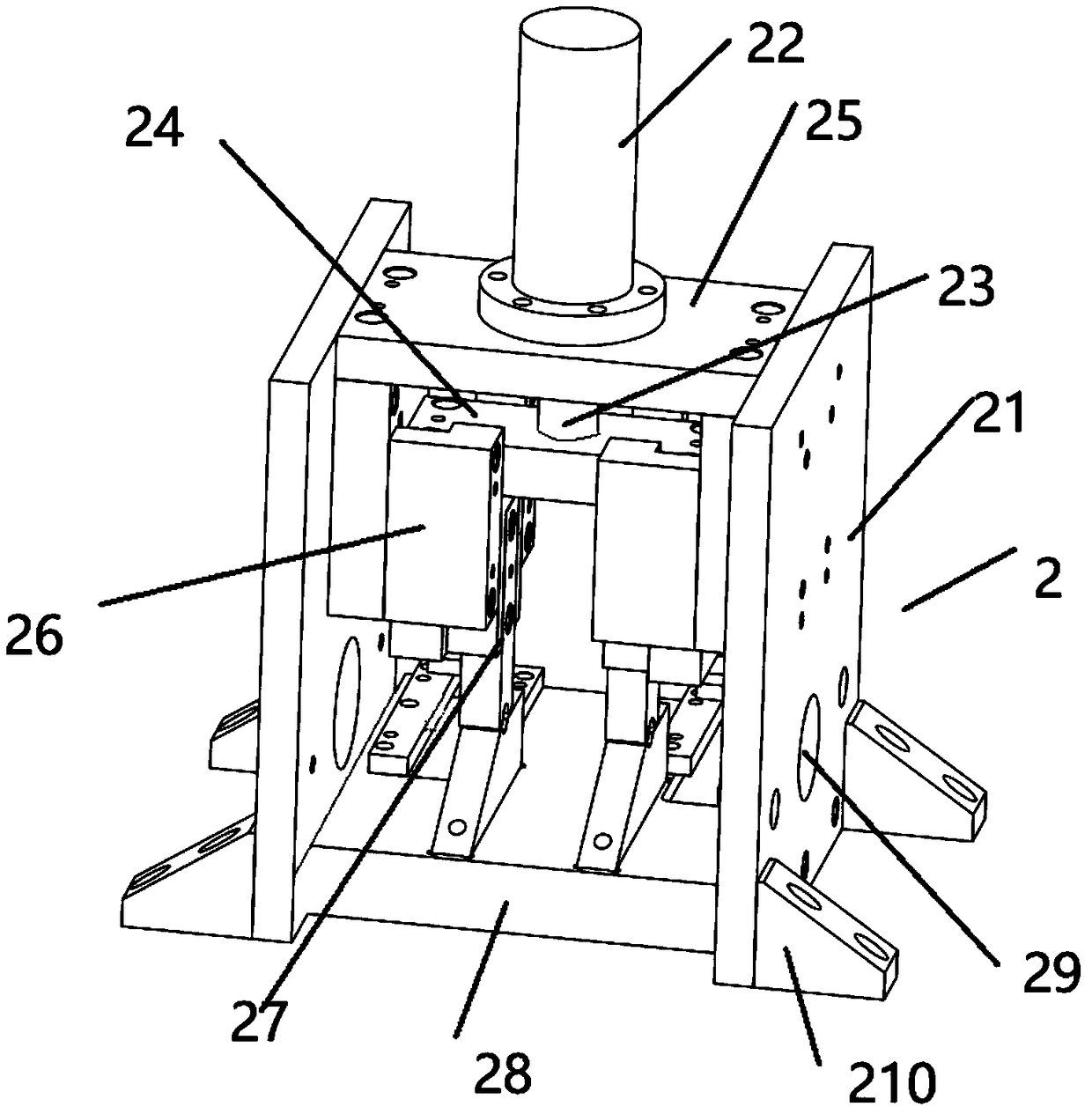

[0022] Such as figure 1As shown, a shaft tube chamfering device for transmission shaft processing proposed by the present invention includes a workbench 1 welded on the top of the frame 5, a fixing mechanism 2 fixed in the middle of the workbench 1, a chamfering mechanism 3 and The feeding mechanism 4 and the two chamfering mechanisms 3 are respectively arranged on both sides of the fixing mechanism 2, the feeding mechanism 4 is installed behind the fixing mechanism 2, and the chamfering mechanism 3 and the feeding mechanism 4 are all fixed on the workbench 1, and the fixing mechanism 2 is used to engage and fix the shaft tube, two chamfering mechanisms 3 respectively chamfer the left and right ends of the shaft tube, and the feeding mechanism 4 is used for automatic feeding; the fixing mechanism 2 includes two first fixing plates 21 arranged in parallel And the pressure plate 27, the first fixing plate 21 is vertically fixed on the workbench 1 through the first mounting foot ...

Embodiment 2

[0024] In addition, please continue to refer to Figure 2-5 , different from the above-mentioned embodiment, the first moving plate 47 both sidewalls are provided with a limit plate 48, the limit plate 48 is a rectangular plate, the limit plate 48 is fixed on the fixed seat 28 by bolts, so that the limit plate 48 can be used 48 to engage both sides of the first shifting plate 47 to ensure that the first shifting plate 47 can move according to a fixed track. The first shifting plate 47 is a square plank, the second shifting plate 49 is a triangular plank, and the second shifting plate 49 is concave at the top. A groove with an arc-shaped structure is provided, and the groove is located directly below the rubber stopper 411. The first moving plate 47 and the second moving plate 49 are connected by bolts, and a torsion spring is sleeved outside the bolt, and the two ends of the torsion spring Connect the first shifting plate 47 and the second shifting plate 49 respectively, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com