Automatic assembly and tray arrangement equipment for computer screens

A technology of automatic assembly and computer screen, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc. It can solve the problems of inability to arrange neatly and inconvenient assembly, and achieve the effect of high assembly efficiency, convenient assembly, and convenient subsequent assembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

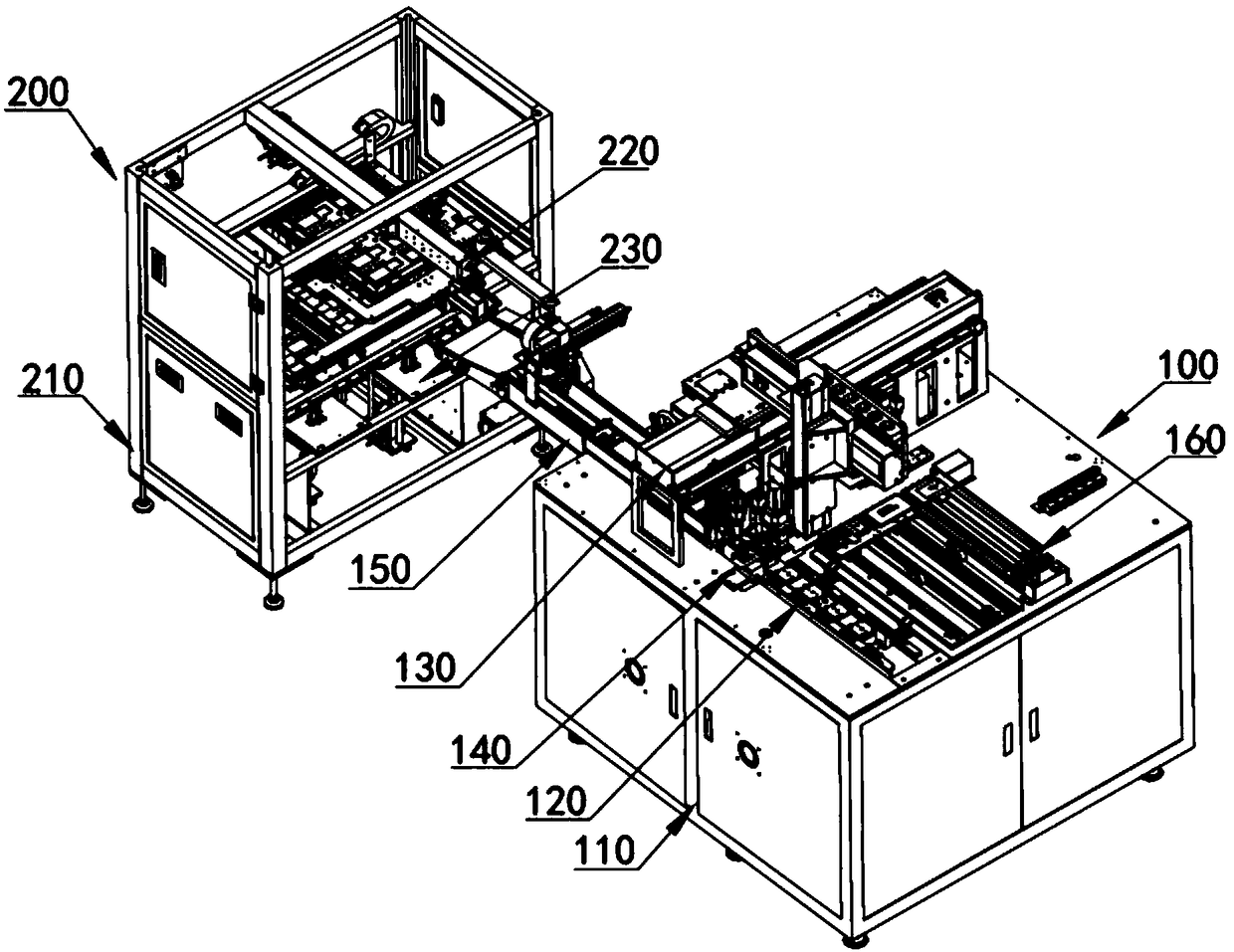

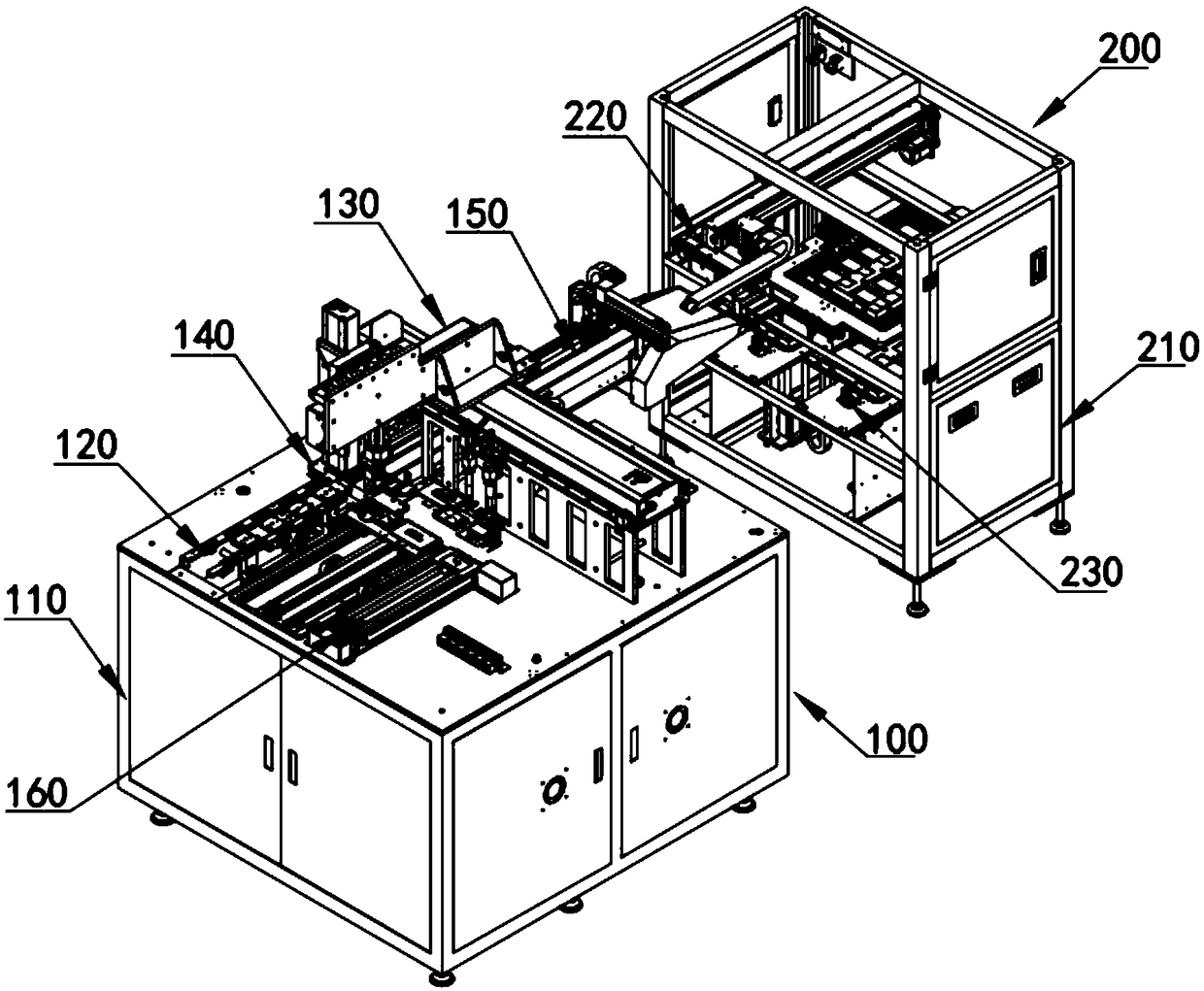

[0027] Such as Figure 1 ~ Figure 2 As shown, a computer screen automatic assembly plate arrangement device includes an assembly device 100 and a plate arrangement device 200 connected to the assembly device 100. The assembly device 100 includes a first frame 110, which is arranged on the first frame 110. The feeding device 120 is arranged on the first frame 110 and is positioned at the reclaiming device 130 on one side of the feeding device 120. The rack is positioned at the feeding device 150 below the retrieving device 130, and the plate swinging device 200 is positioned at one side of the feeding device 150; , the stacking device 230 located below the discharging device 220 .

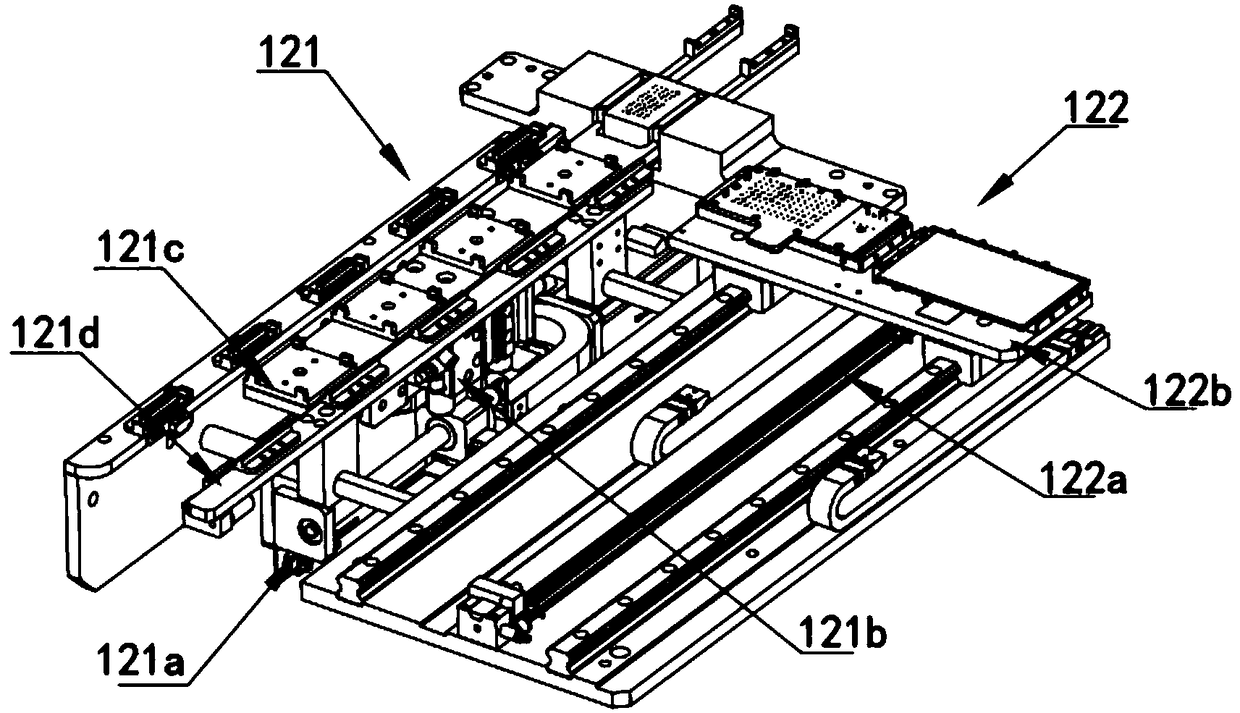

[0028] Such as image 3 As shown, the feeding device 120 includes a first feeding assembly 121 and a second feeding assembly 122, at least two sets of feeding assemblies are provided, whi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap