An agricultural plastic film greenhouse automatic installation robot

A plastic film, automatic installation technology, applied in the direction of the workpiece clamping device, manufacturing tools, etc., can solve the problems of difficult to connect the arch rod and the connecting pipe, difficult to grasp the arch rod and the connecting pipe, the process is cumbersome and complicated, etc., to achieve time-consuming Short, efficient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

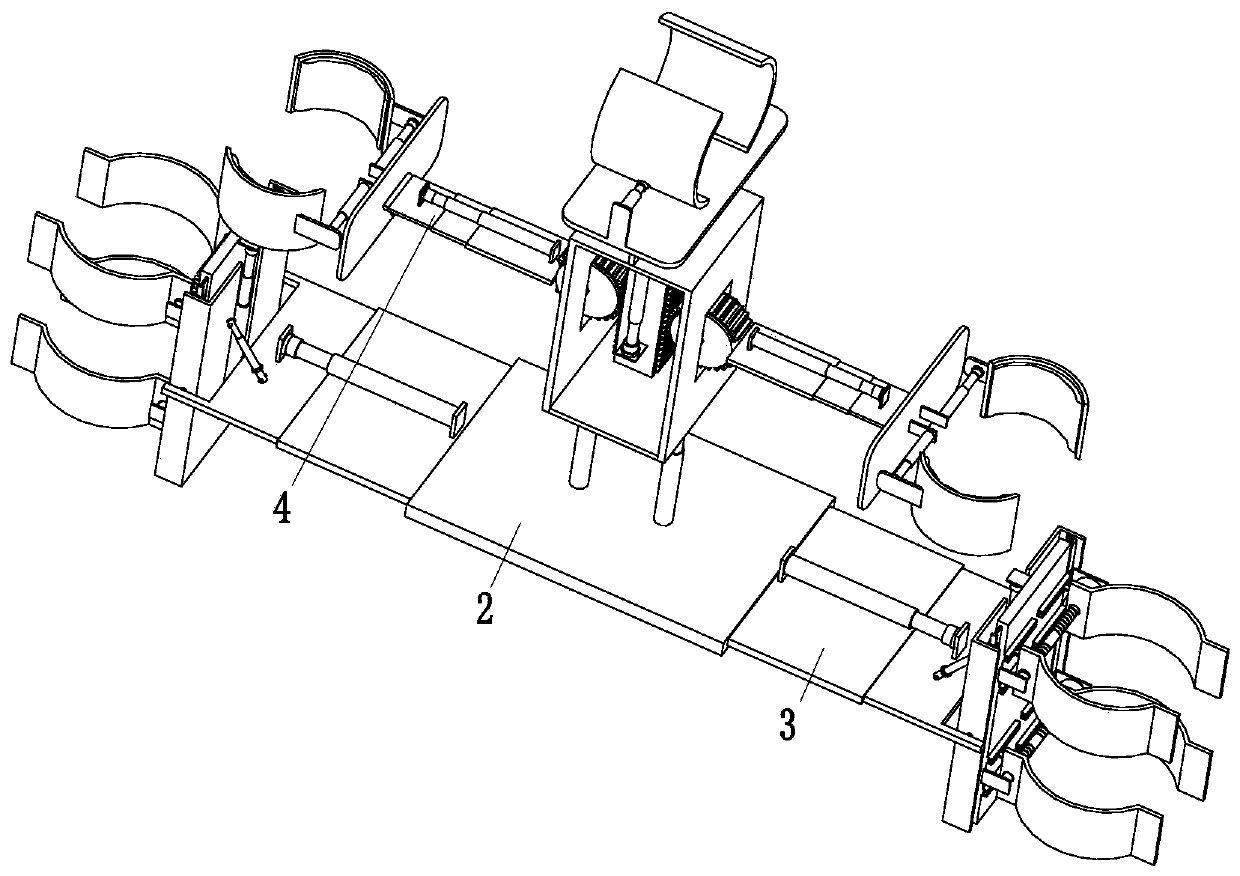

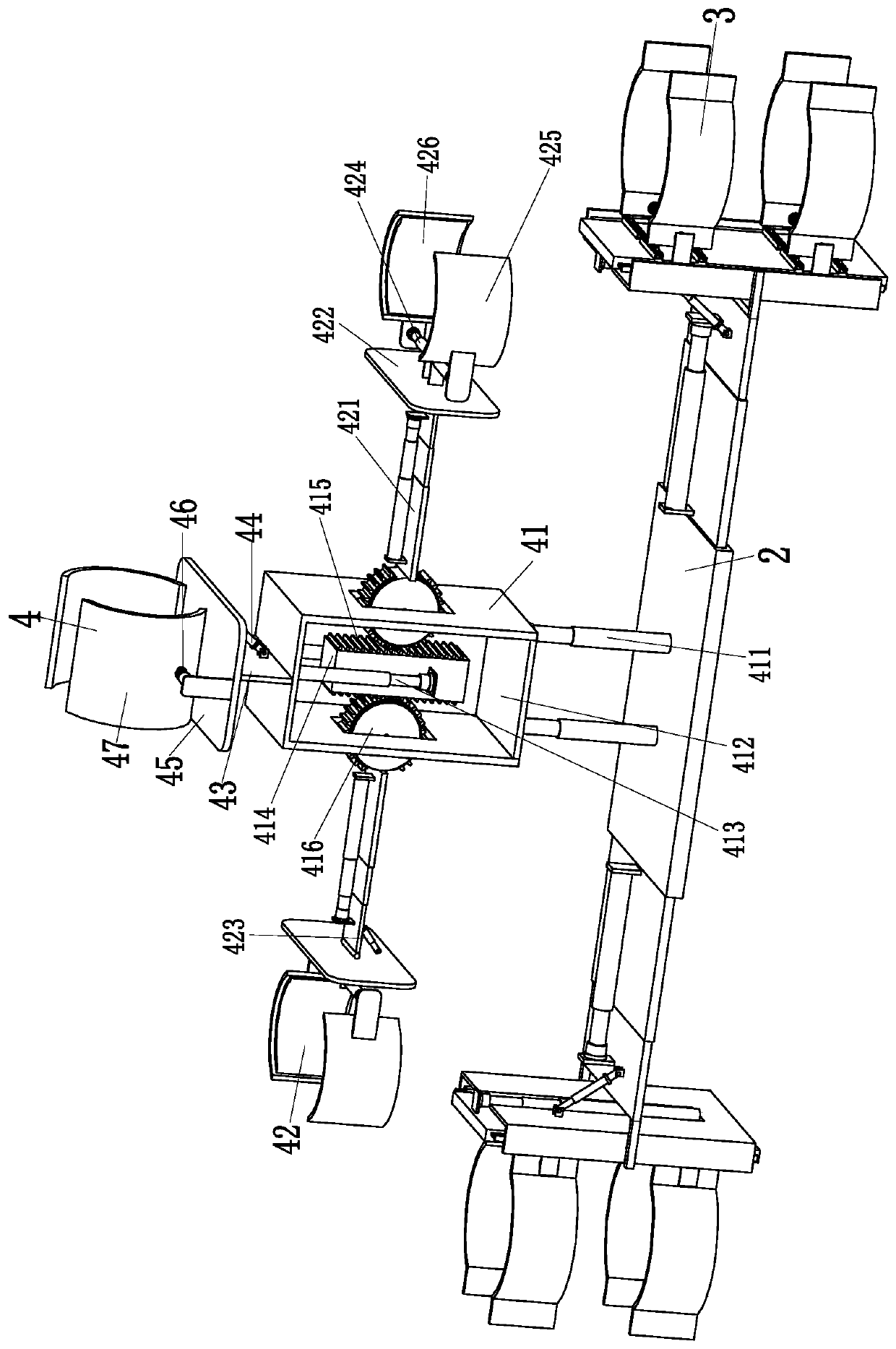

[0024] Such as Figure 1 to Figure 4 As shown, an automatic installation robot for agricultural plastic film greenhouses includes a main board 2, two arch installation devices 3, and a connecting pipe fixing device 4. The left and right ends of the main board 2 are equipped with two arch installation devices 3, A connecting pipe fixing device 4 is installed on the upper end of the main board 2.

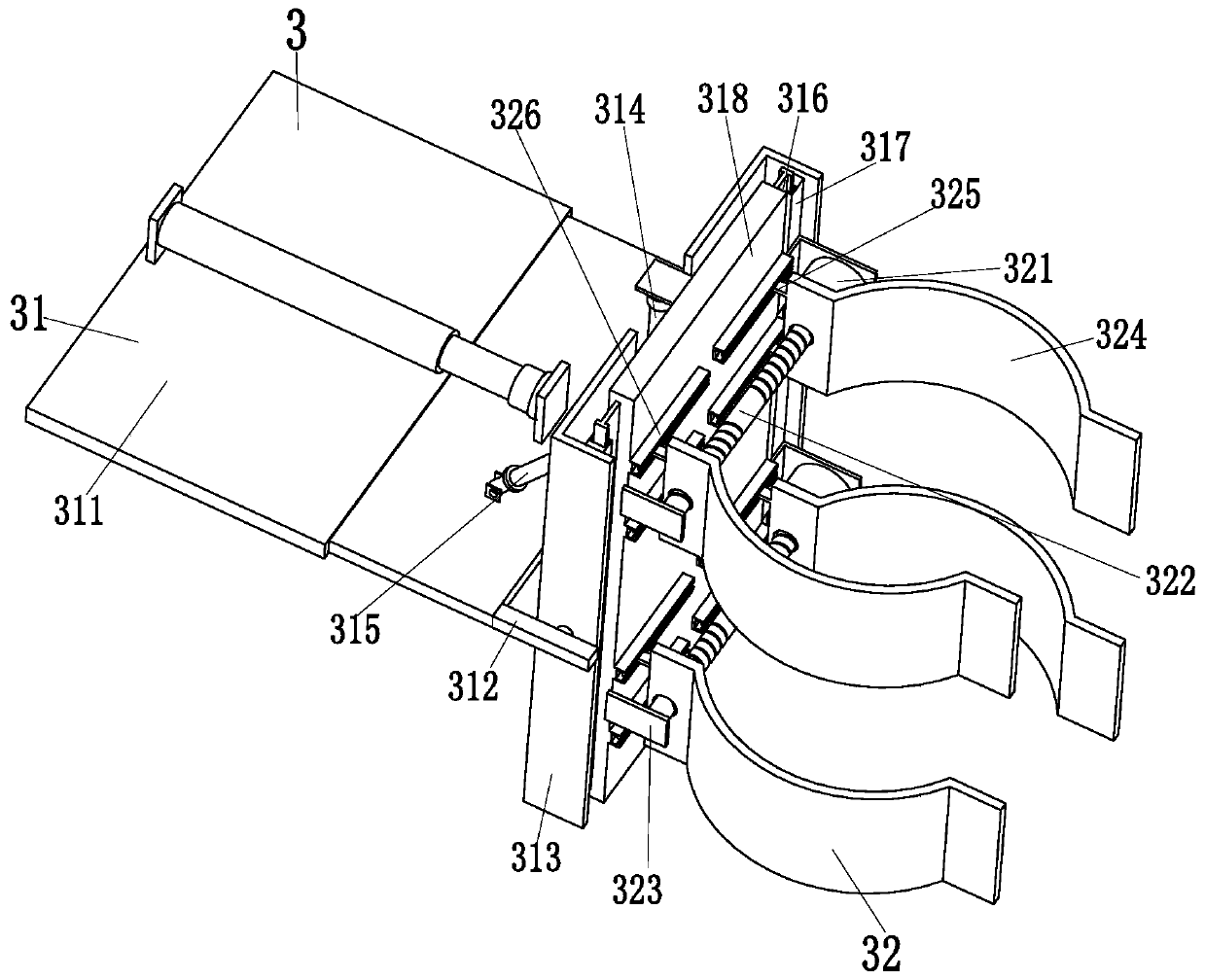

[0025] The arch rod installation device 3 includes an adjusting and pushing mechanism 31 and a clamping mechanism 32. The adjusting and pushing mechanism 31 is installed on the side wall of the main board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com