Threaded swing-type chain-like robot

A robot, chain-like technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large display space and single action, and achieve the effect of small size, space saving, and high controllability of movement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

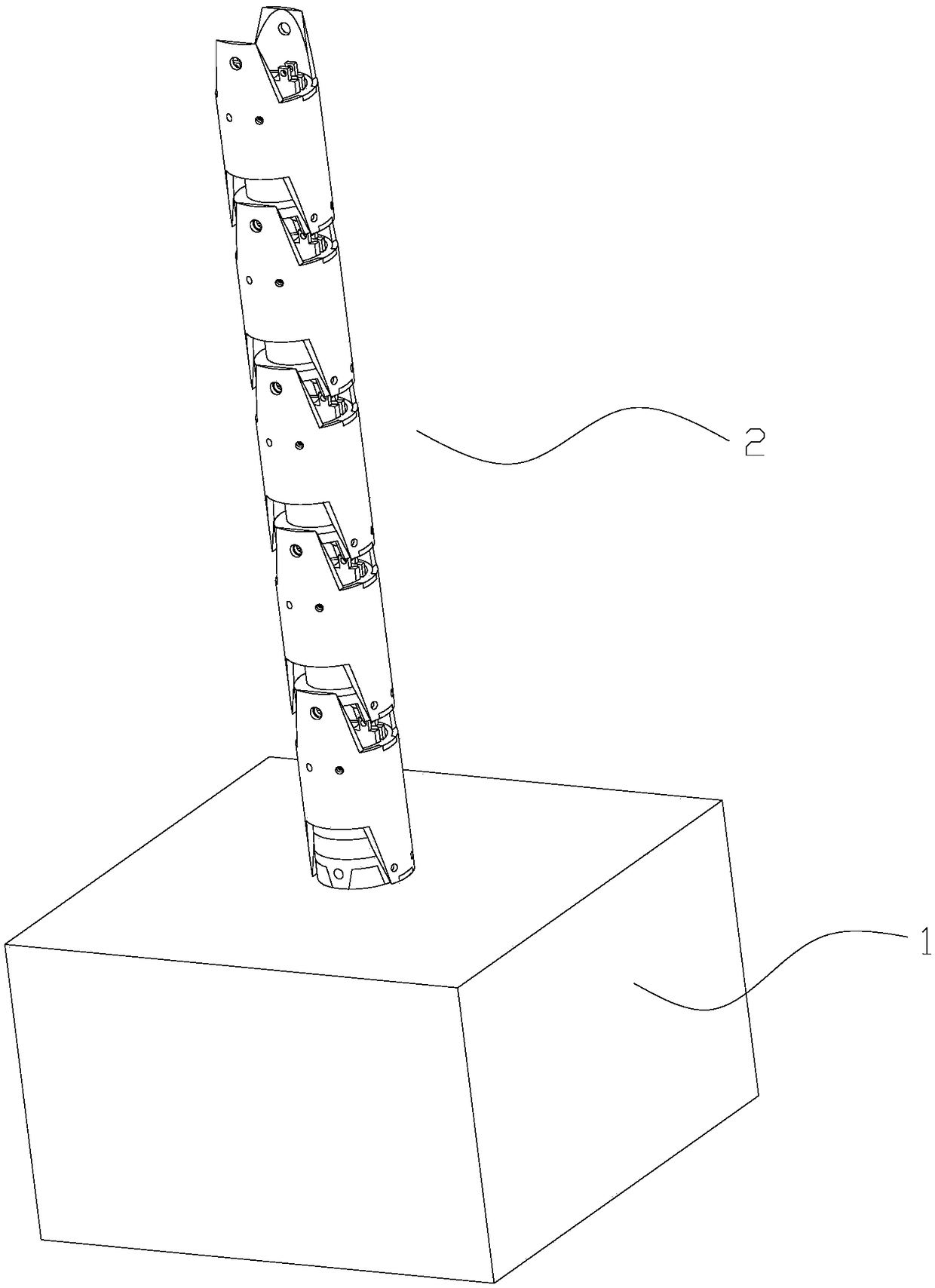

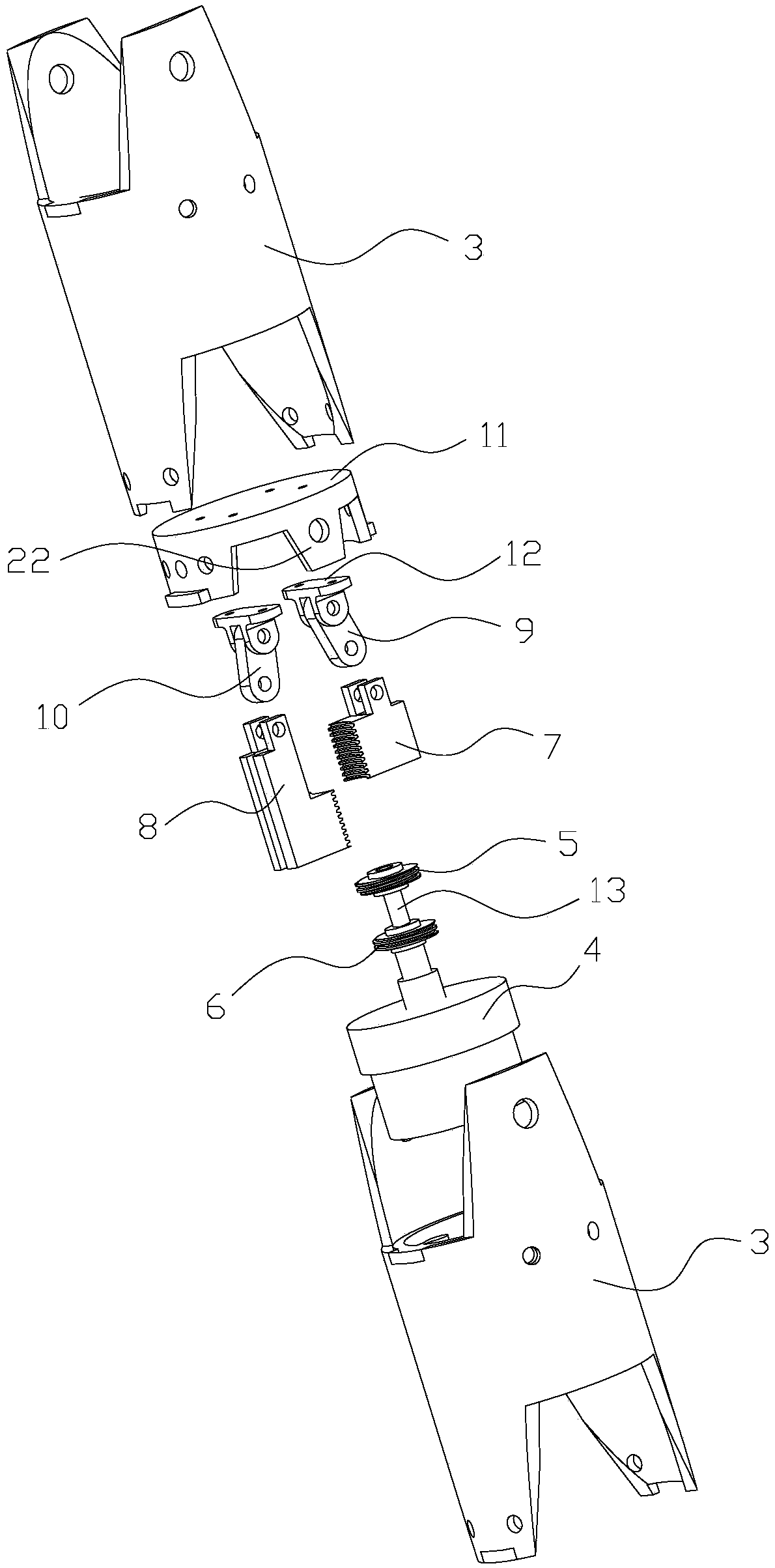

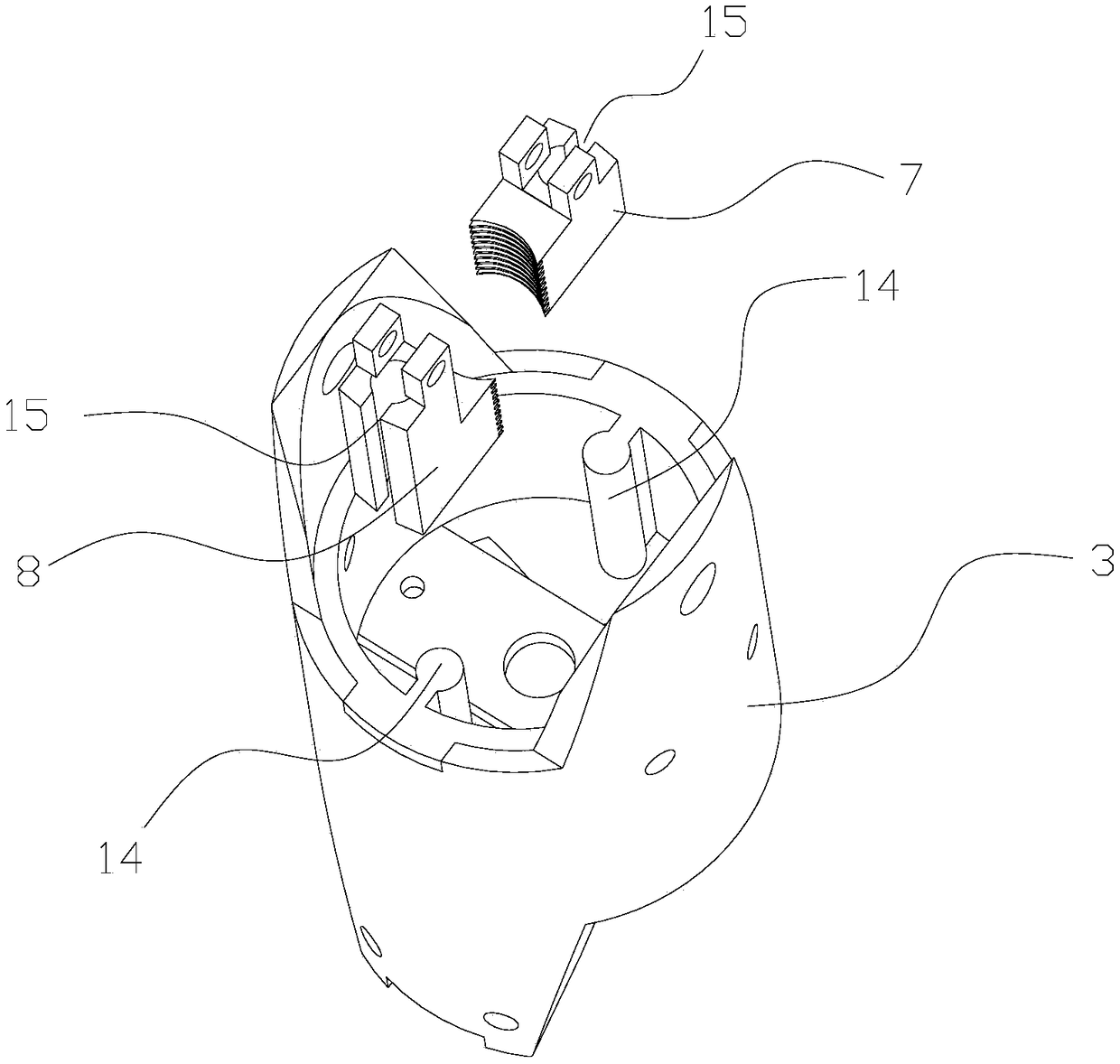

[0043] see Figure 1 to Figure 5 , the present invention discloses a threaded swinging chain robot, including a base body 1, and a manipulator body 2 installed on the base body 1; wherein, the manipulator body 2 includes a plurality of linked movable joints 3, and two adjacent movable joints The joints 3 are hinged to each other, and are driven by a joint assembly located inside the movable joint 3; a control unit is provided inside the base body 1, and each joint assembly is controlled and connected to the control unit through a circuit;

[0044] The joint assembly includes a unit motor 4, a right-handed screw rod 5, a left-handed screw rod 6, a right-hand thread transmission arm 7, a left-hand thread transmission arm 8, a first connecting rod 9, a second connecting rod 10 and a swing member 11; the unit motor 4 It is fixedly installed inside the movable section 3 located on the next floor and connected to the control unit. The unit motor 4 is connected with a right-handed sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com