A method for dismantling and recycling scrapped vehicles

A technology for recycling and scrapping automobiles, which is applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems that do not meet development requirements, high labor intensity, and low processing efficiency, so as to increase adsorption effect, save costs, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

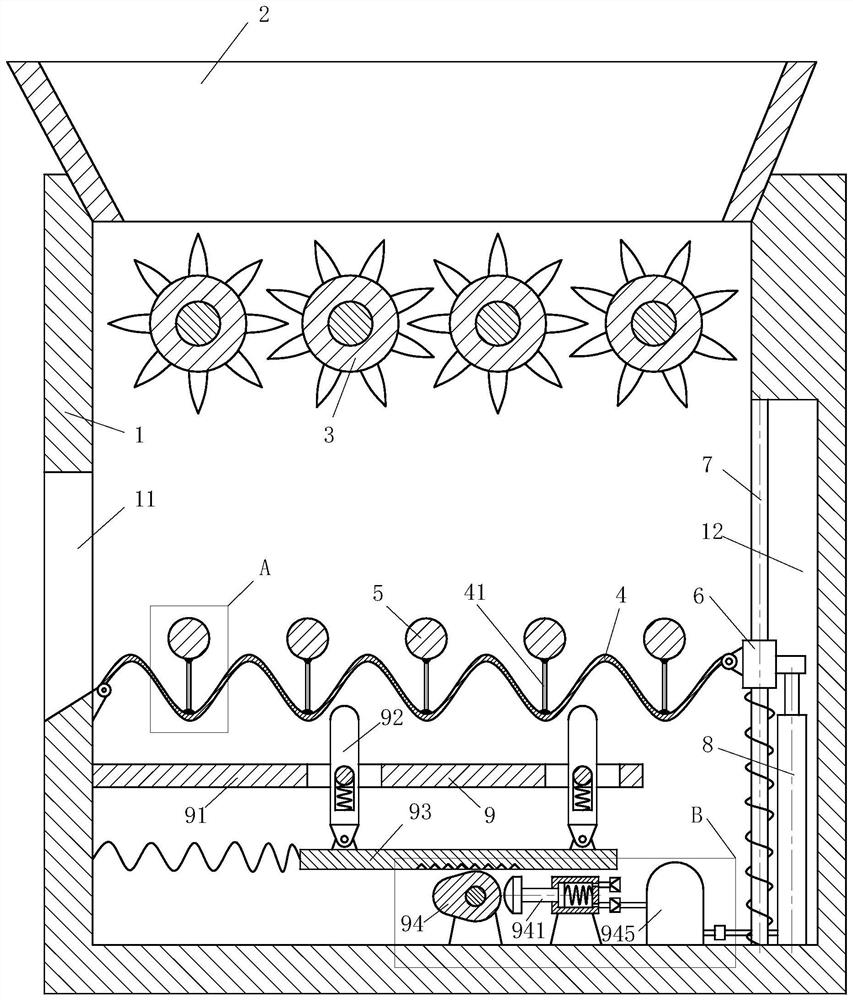

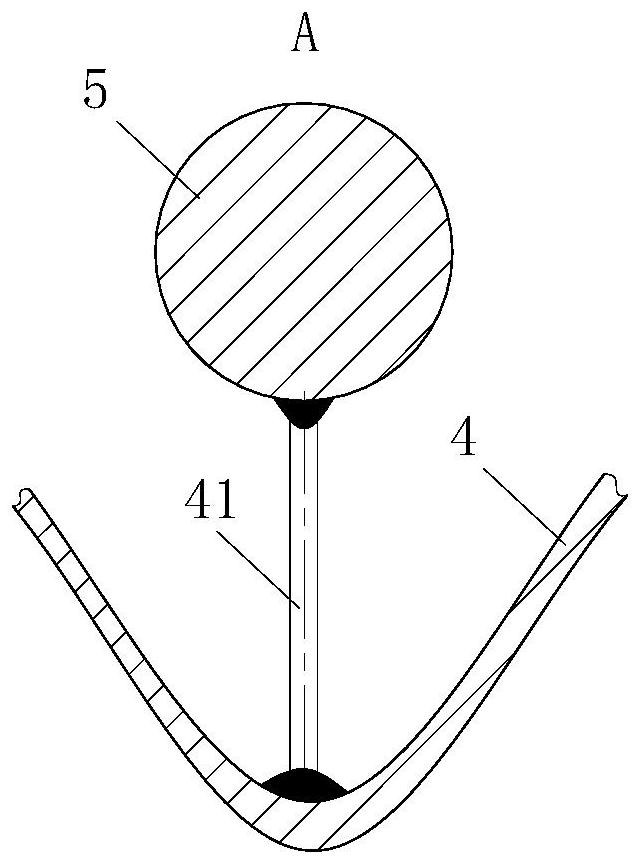

[0029] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

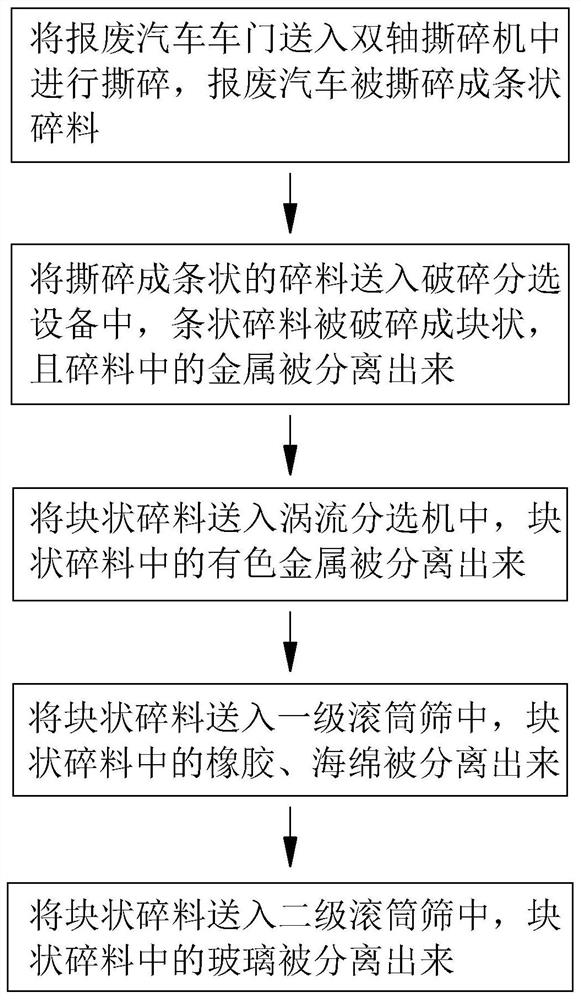

[0030] like Figure 1 to Figure 4 As shown, a method for dismantling and recycling scrapped vehicles according to the present invention, the method comprises the following steps:

[0031] Step 1: Send the door of the scrapped car into a double-shaft shredder for shredding, and the scrapped car is shredded into strips of scrap;

[0032] Step 2: The scraps shredded into strips in step 1 are sent to the crushing and sorting equipment, the strips are broken into blocks, and the metal in the scraps is separated;

[0033] Step 3: The blocky debris in step 2 is sent to the eddy current separator, and the non-ferrous metals in the blocky debris are separated;

[0034] Step 4: The blocky debris in step 3 is sent to the first-level trommel screen, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com