Scraped vehicle resourceful treatment method

A technology for scrapped cars and treatment methods, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve problems such as water pollution, soil pollution, environmental pollution, etc., to reduce environmental pollution, improve utilization, ensure Efficient and automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

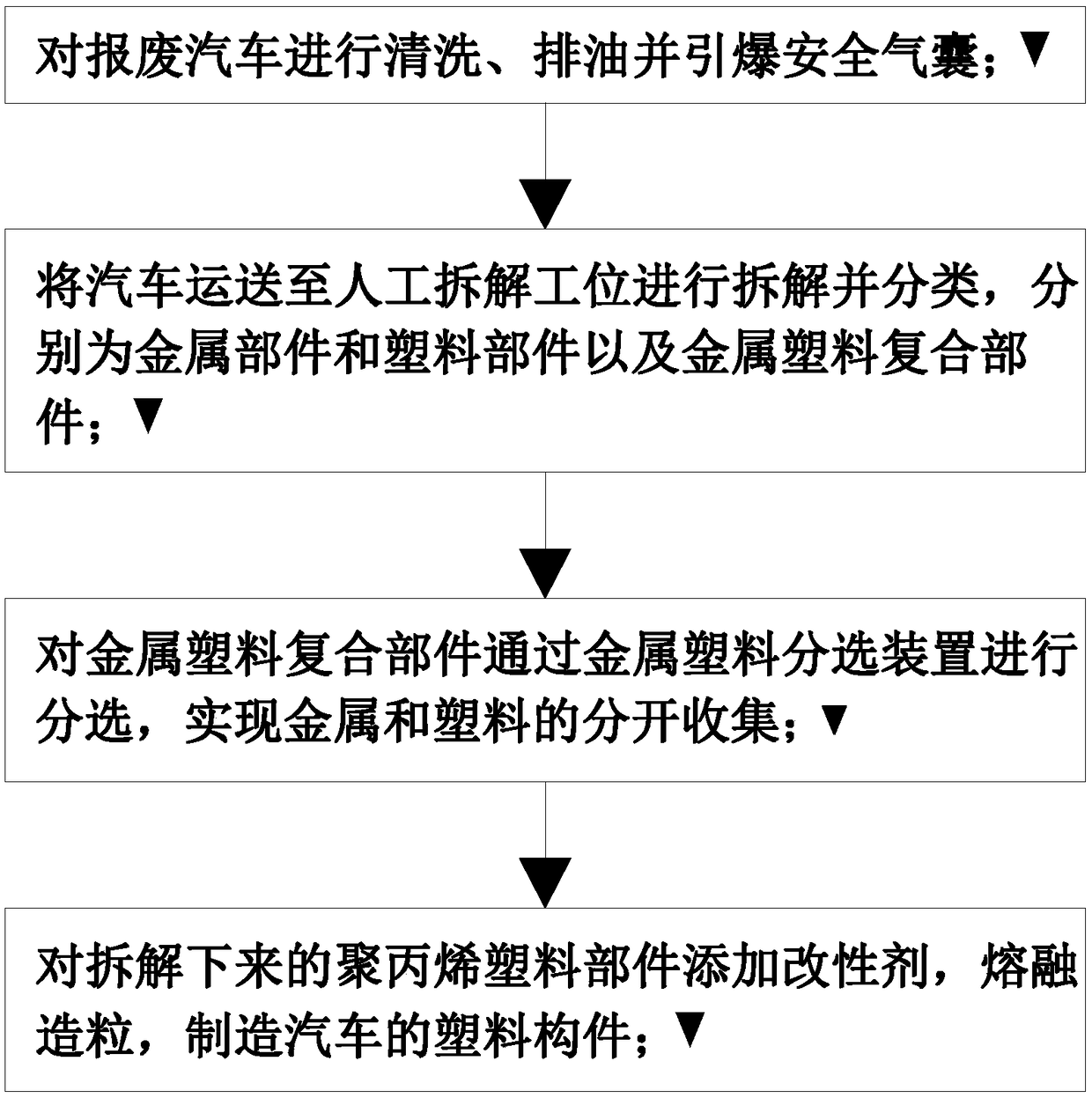

[0026] use Figure 1-Figure 4A method for recycling scrapped automobiles according to an embodiment of the present invention will be described as follows.

[0027] Such as figure 1 and figure 2 As shown in the present invention, a method for recycling scrapped automobiles, the method comprises the following steps:

[0028] Step 1: Clean the scrapped car, drain the oil and detonate the airbag;

[0029] Step 2: After step 1 is completed, the car is transported to the manual dismantling station for dismantling and classification, which are respectively metal parts, plastic parts and metal-plastic composite parts;

[0030] Step 3: Sorting the metal-plastic composite parts in step 2 through a metal-plastic sorting device to realize separate collection of metal and plastic;

[0031] Step 4: Add modifiers to the disassembled polypropylene plastic parts, melt and granulate them, and manufacture plastic components of automobiles;

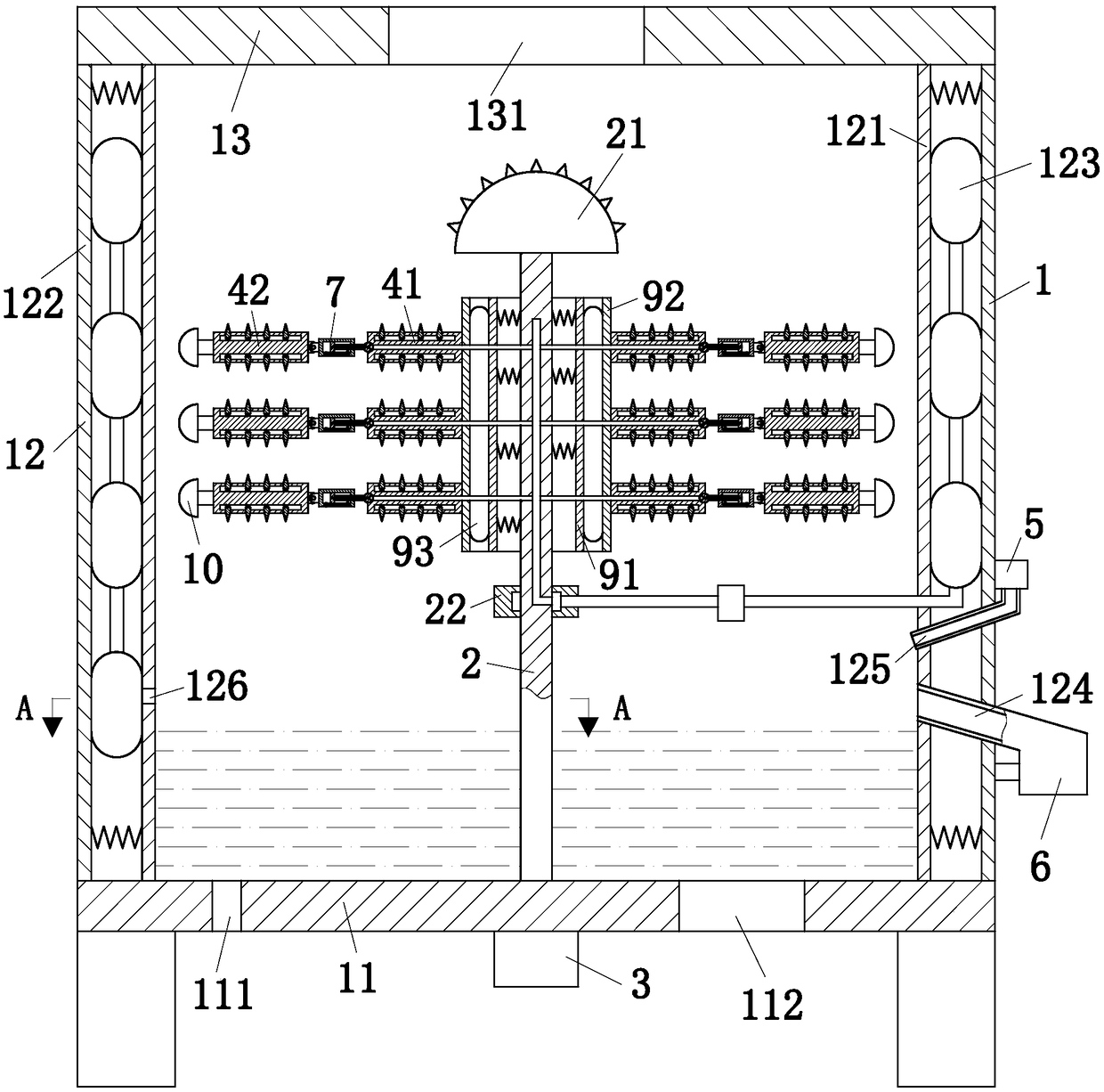

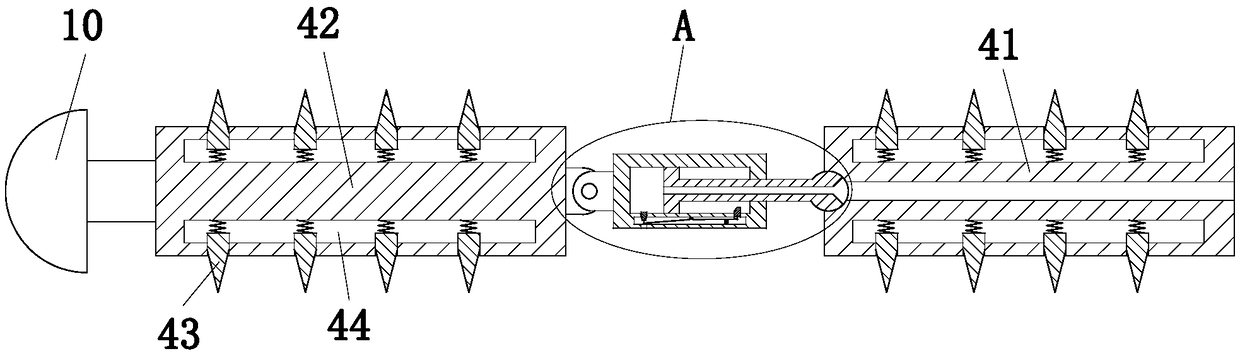

[0032] Wherein, the metal-plastic sorting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com