Replaceable forming mold and soldering tin sleeve forming equipment and method

A technology for forming molds and forming equipment, which is applied in the field of production equipment and process improvement of heat-shrinkable sleeves, can solve the problems of inability to meet production requirements, inability to automate batch production, and low processing efficiency, so as to achieve convenient repair and maintenance, and convenient Mounting and dismounting, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

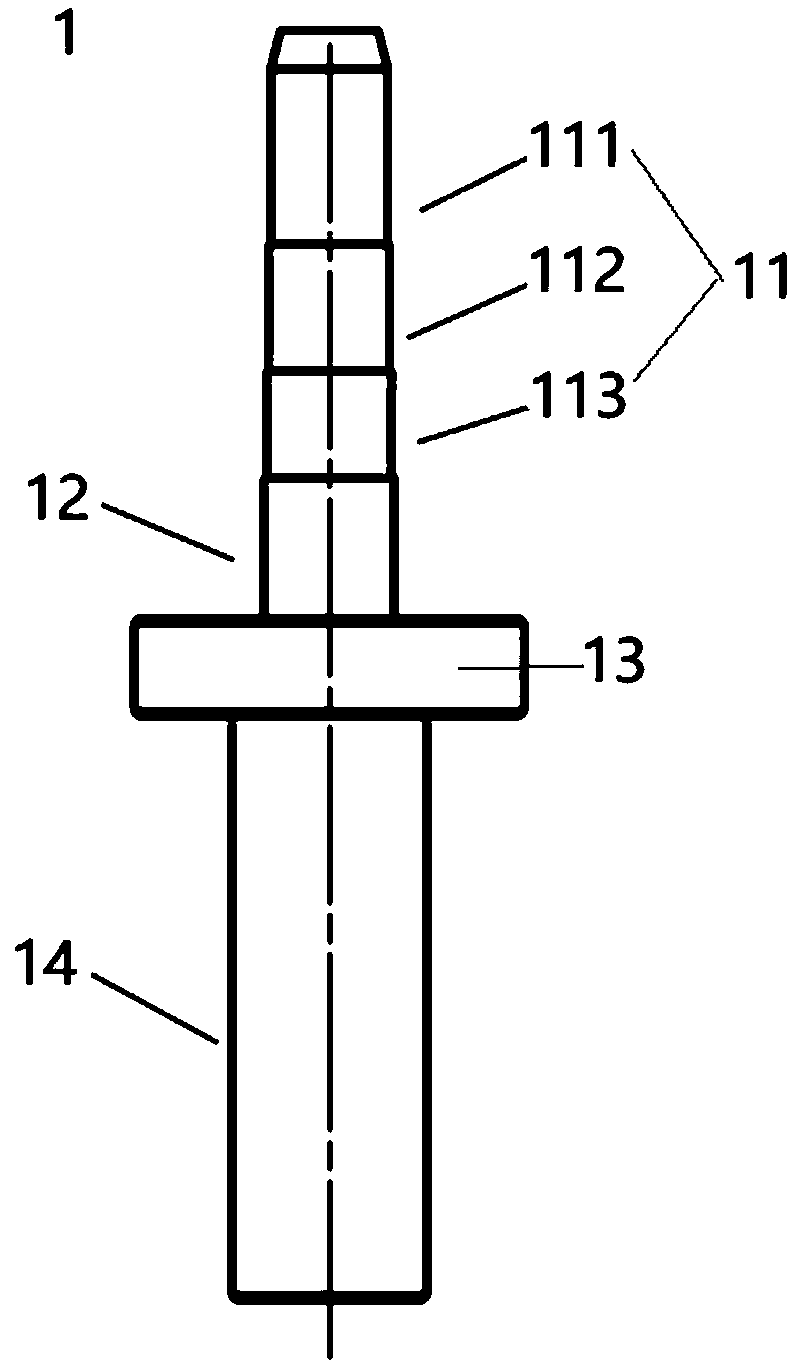

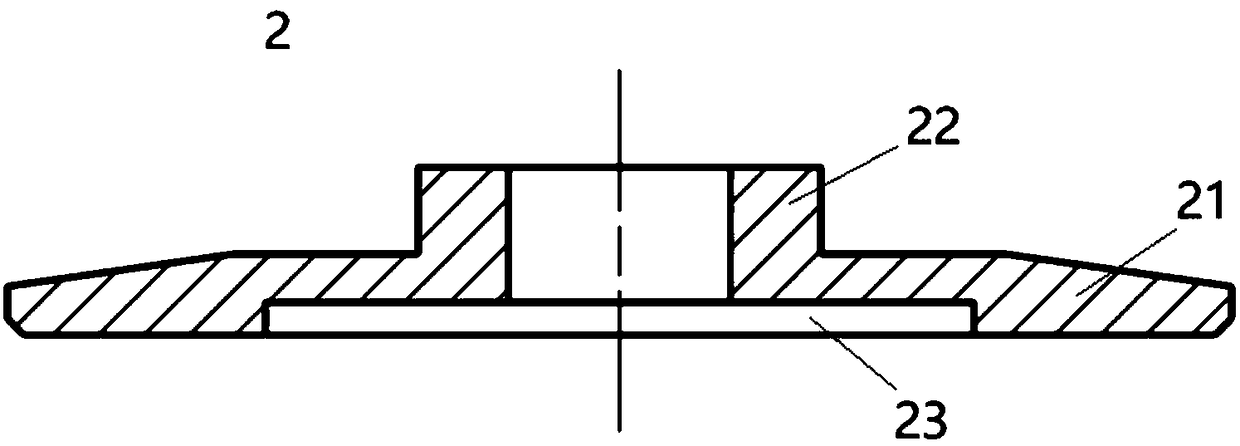

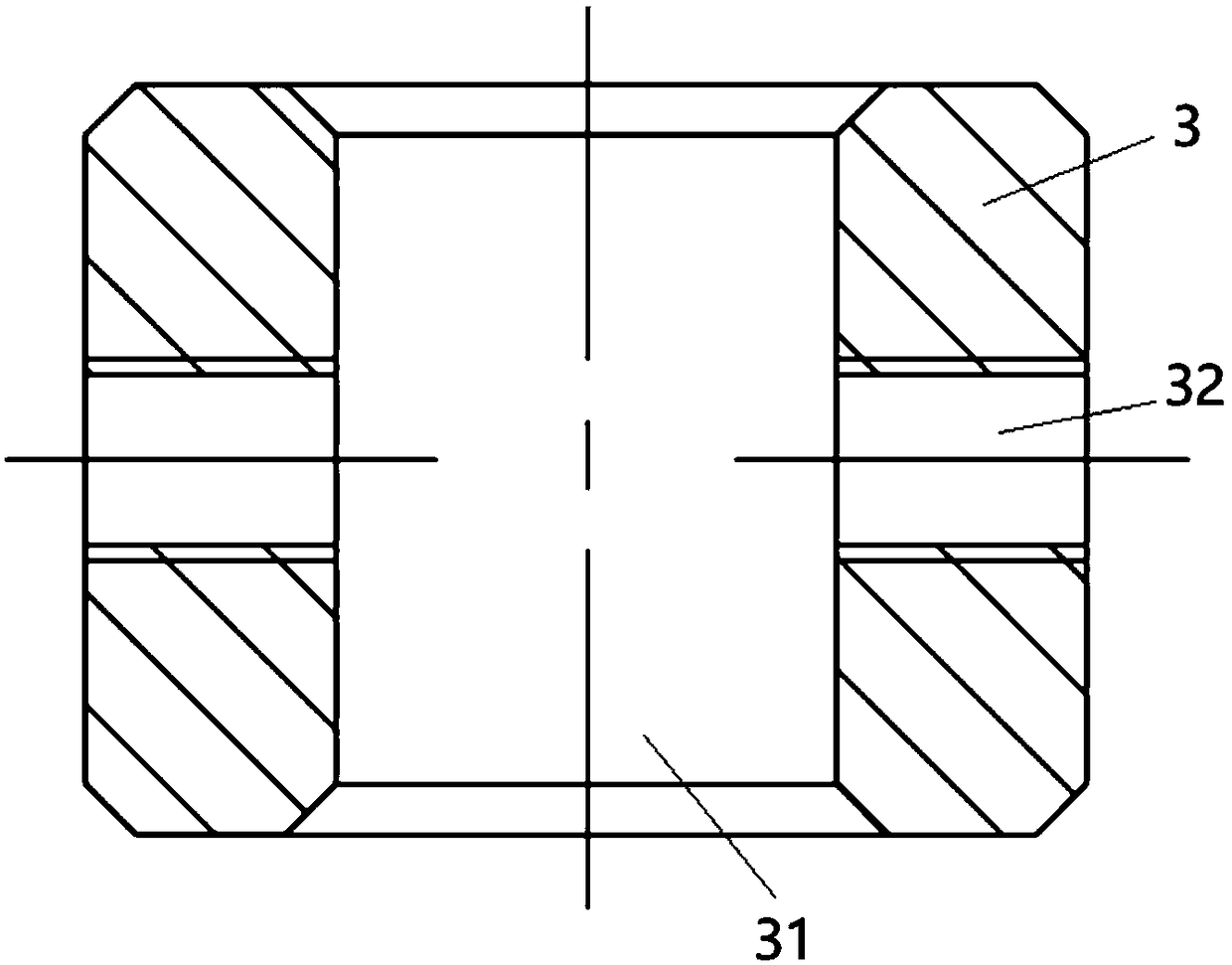

[0035] Such as Figure 1~3 As shown, this specific embodiment discloses a replaceable molding die, including: a stepped shaft 1, a gasket 2 and a fixing member 3, wherein the stepped shaft 1 includes a collar step 11, a gasket step 12, The snap ring step 13 and the locking step 14, the collar step 11 includes the first step 111, the second step 112 and the third step 113 whose outer diameter increases sequentially, the third step 113 is connected with the gasket step 12, and the gasket step 12 The outer diameter of the collar step 11 is greater than the outer diameter of the third step 113, and the outer diameter of the snap ring step 13 is greater than the outer diameter of the gasket step 12 and the locking step 14. Wherein, the first step 111 , the second step 112 and the third step 113 are respectively used for installing the first rubber ring, the tin ring and the second rubber ring.

[0036] In this embodiment, the gasket 2 is detachably sleeved on the gasket step 12 an...

specific Embodiment 2

[0040] This specific embodiment discloses a solder sleeve molding equipment, including: the replaceable molding die disclosed in the first specific embodiment, an operating platform and a heating device, the operating platform has a mounting hole, and the diameter of the mounting hole is larger than or It is equal to the outer diameter of the locking step in the stepped shaft, and the diameter of the installation hole is smaller than the outer diameter of the snap ring step in the stepped shaft. In this way, after the locking step of the stepped shaft passes through the operating platform, the snap ring step can be stuck on the operating platform On the upper surface of the upper surface, then fix the fixing part on the locking step, so that the fixing part is stuck on the lower surface of the operating platform, and the axial positioning of the stepped shaft can be completed through the cooperation of the snap ring step, the fixing part and the operating platform. After the st...

specific Embodiment 3

[0045] This specific embodiment discloses a method for forming a solder sleeve. The method specifically adopts the solder sleeve forming equipment in Embodiment 2. The automatic ring adding method includes the steps:

[0046] S10: Thread the locking step in the stepped shaft into the installation hole of the operating platform, and the snap ring step in the stepped shaft is stuck on the upper surface of the operating platform;

[0047] S20: Fix the fixing part on the locking step in the ladder shaft, and the fixing part is stuck on the lower surface of the operation platform;

[0048] S30: set the gasket on the gasket step;

[0049] S40: Sleeve the first rubber ring, the tin ring, and the second rubber ring on the first step, the second step, and the third step of the collar steps in sequence;

[0050] S50: Put the heat-shrinkable sleeve on the gasket after passing through the step of the collar;

[0051] S60: Heat the heat-shrinkable sleeve located at the collar through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com