A production line for earphone sets with shells

An earphone cover and production line technology, which is applied in the field of the production line of the earphone cover with a shell, can solve problems such as a large number of manual operations, and achieve the effect of reducing the floor space and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

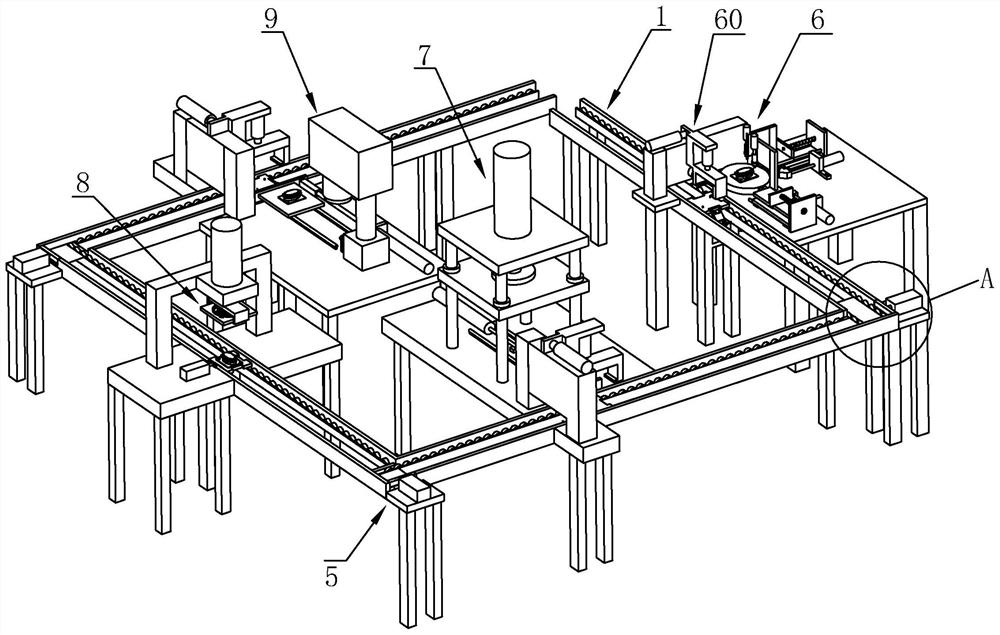

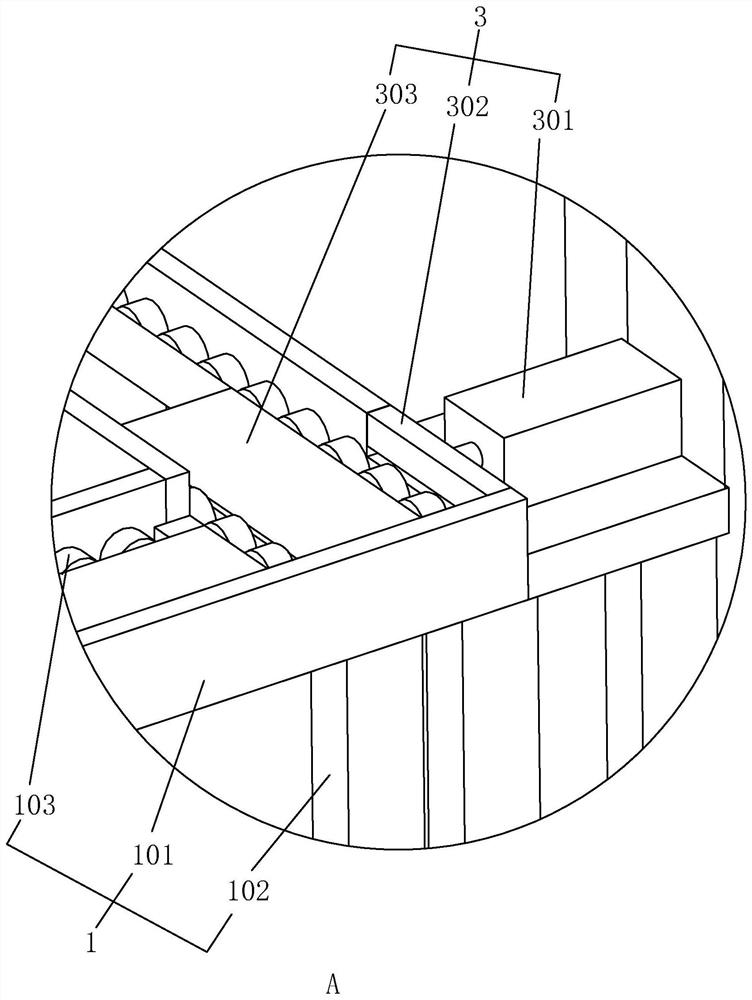

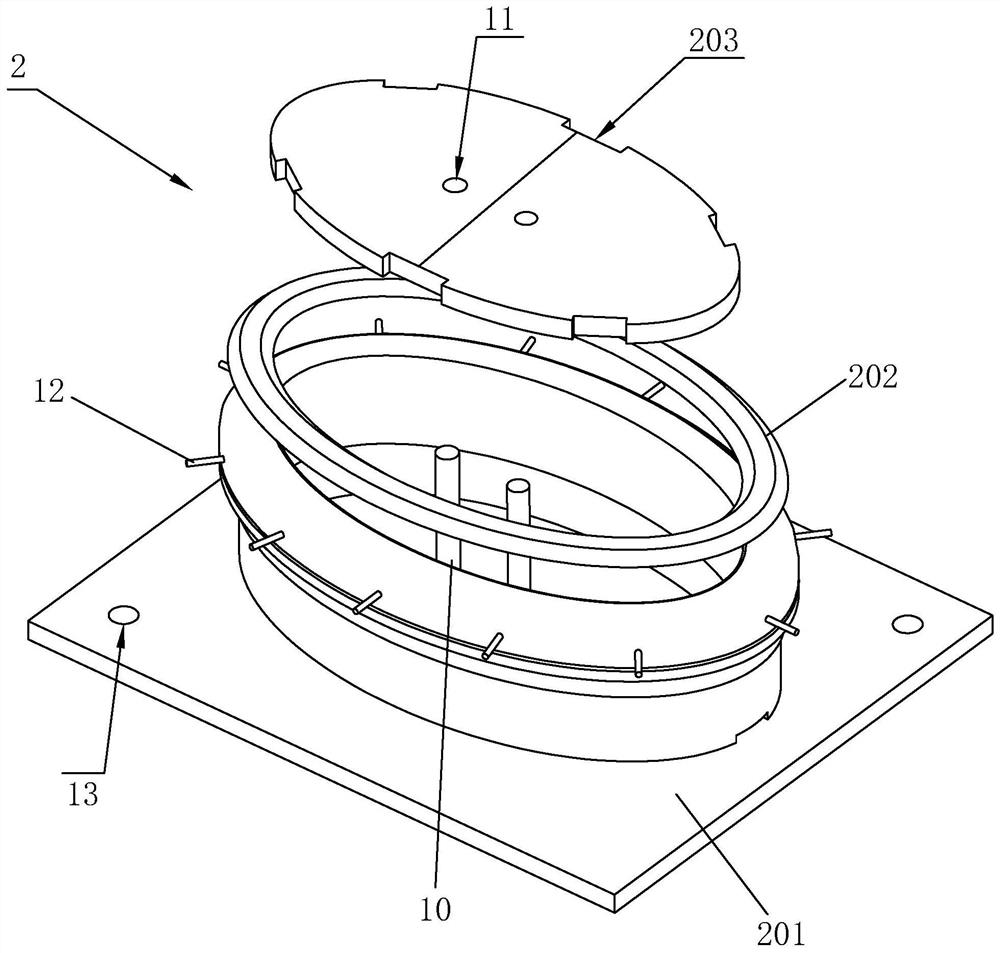

[0051] Embodiment 1: A production line for earphone sets with shells, refer to figure 1 , including a conveyor table 1, a mold 2 for mounting the dough on the plastic shell, and a stage 4 that is slidably arranged on the conveyor table 1 and used to place the mold 2 (refer to Figure 4 ), the stage 4 is fixedly provided with a stage guide column 401, and the conveying stage 1 is sequentially connected with a dispensing device 6 for dispensing the connection between the dough and the rubber shell installed in the mold 2, and the point The glued mold 2 is used to cut the scraped dough edge 7, the curling device 8 is used to paste the punched dough edge structure on the rubber shell, and the ultrasonic fusion device is used to firmly press the dough edge structure and the rubber shell 9 and a steering device 3 for changing the direction of the loading platform 4 on the conveying platform 1 .

[0052] refer to figure 1 and figure 2 , the conveying platform 1 is set in a frame ...

Embodiment 2

[0083] Embodiment 2: A production line for earphone sets with shells, refer to image 3 and Figure 14 The difference between the embodiment of the present invention and the first embodiment is that the curling device is different, and the curling device includes a square plate-shaped curling storage plate 86, four second curlings fixedly installed on the upper surface of the curling storage plate 86 The cylinder 87 and the second crimping plates 88 fixedly connected to the piston rods of the four second crimping cylinders 87 are respectively provided with crimping contact grooves 881 on one side surfaces of the four second crimping plates 88 .

[0084] Specifically, the four second curling cylinders 87 are distributed in a circular array on the upper surface of the curling storage board 86, and the lengthwise extension of the piston rods of the four second curling cylinders 87 can form a cross-shaped frame, and the four The end of the piston rod of the second crimping cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com